Novel application of waterborne polyurethane, and waterborne polyurethane cooling coating and preparation method thereof

A water-based polyurethane, a new-purpose technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

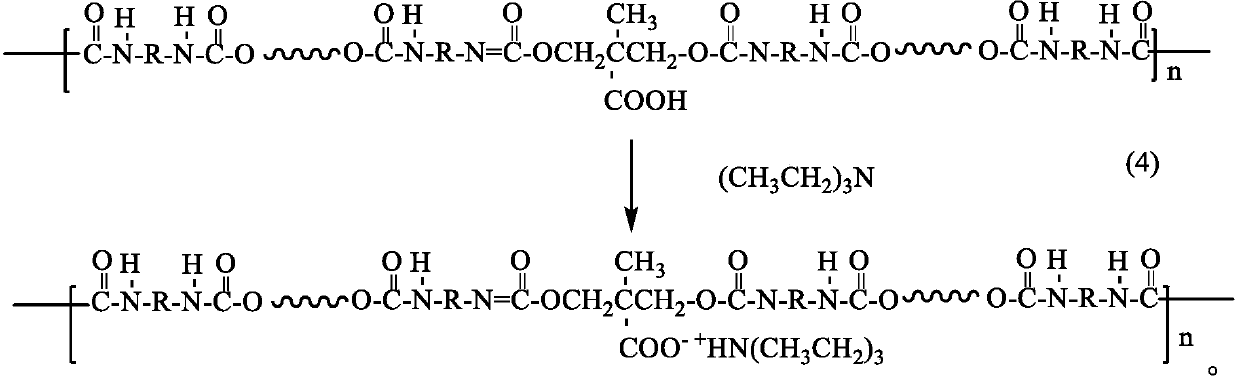

[0024] Embodiment 1: Synthesis and performance test of aqueous polyurethane emulsion

[0025] 1. Synthesis of water-based polyurethane emulsion: The raw materials and proportions (by weight and number) used are: 0.1-0.2 parts of dibutyltin dilaurate, 10-15 parts of polypropylene glycol 2000, and 1,4-butyl polyadipate 5-8 parts of diol ester, 1.3-2 parts of 2,2-dimethylolpropionic acid, 10-15 parts of isophorone diisocyanate, 0.5-0.85 parts of pentaerythritol, 6-8 parts of acetone, 1,4- 1.5-2 parts of butanediol, 0.8-1.2 parts of triethylamine, 1-2 parts of γ-aminopropyl triethoxysilane, 55-60 parts of water (deionized water).

[0026] The synthesis steps are as follows:

[0027] ① 2,2-Dimethylolpropionic acid and pentaerythritol were dehydrated under reduced pressure at 80°C for 2 hours.

[0028] ② Dry polypropylene glycol, dibutyltin dilaurate and poly-1,4-butylene adipate under reduced pressure at 120°C for 2 hours, cool down to 85°C, and add 2,2-dimethylolpropionic acid ...

Embodiment 2

[0044] Embodiment 2: preparation and performance test of waterborne polyurethane cooling coating

[0045] 1. Prepare water-based polyurethane cooling coating: raw materials and proportioning (weight and number ratio): 90-95 parts of water-based polyurethane emulsion prepared in embodiment 1, 30-50 parts of filler (filler is calcium carbonate, barium sulfate, diatomaceous earth, One or more of non-reflective fillers with low refractive index such as talcum powder, kaolin, organic bentonite), ammonia water 0-0.5 part (preferably 0.1-0.5 part), color paste 0-1 part, defoamer 0-0.8 parts (preferably 0.5-0.8 parts), dispersant 0-1.0 parts (preferably 0.5-1.0 parts), thickener 0.2-0.6 parts, leveling agent 0-2.5 parts (preferably 1.0-2.0 parts ), 0-15 parts of dipropylene glycol methyl ether (preferably 6-15 parts).

[0046] The preparation steps are as follows:

[0047] 1) Add dispersant and part of defoamer to the aqueous polyurethane emulsion prepared in Example 1 (for example,...

Embodiment 3

[0063] Embodiment 3: Indoor simulated cooling performance test.

[0064] 1. Comparative example of preparation: prepare a water-based polyurethane heat-reflecting cooling coating added with heat-reflecting fillers such as titanium dioxide, and its preparation method is the same as that of the water-based polyurethane cooling coating in Example 2. Three water-based polyurethane heat-reflective cooling coatings added with heat-reflective fillers such as titanium dioxide were prepared as comparative examples. The distribution ratios of each group of the 3 comparative examples are shown in Table 5.

[0065] Table 5 Adding the ratio of water-based polyurethane cooling coatings with heat-reflecting fillers (ratio in parts by weight)

[0066] Component / proportion (ratio by weight) Comparative example 1 Comparative example 2 Comparative example 3 Waterborne Polyurethane Emulsion 90 92 95 ammonia 0.1 0.3 0.5 color paste 0 0.5 1 Dispersant 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com