A method of boron coating

A technology of coating boron and boron powder, which is applied in the field of neutron detection, can solve the problems of low raw material utilization rate and long processing time, and achieve the effects of rich variety, reduced occupation time, and small shape restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In this example, we used nano-sized boron powder particles to coat boron on the aramid paper honeycomb base material with an aspect ratio of 30:1 to make a new thermal neutron converter.

[0088] The boron coating method includes the following steps:

[0089] i) prepare the substrate, clean the surface, weigh and record;

[0090] ii) Coating resin layer

[0091] Prepare an appropriate amount of base resin solution according to the following formula and mix well.

[0092] Resin: curing agent: solvent=250:62.5:1000 (weight ratio).

[0093] Completely immerse the base material in the resin solution for 20 minutes, take out the base material, drain it slightly, and bake it in an oven at 140°C for 30-40 minutes to fully harden the resin and evaporate the solvent completely.

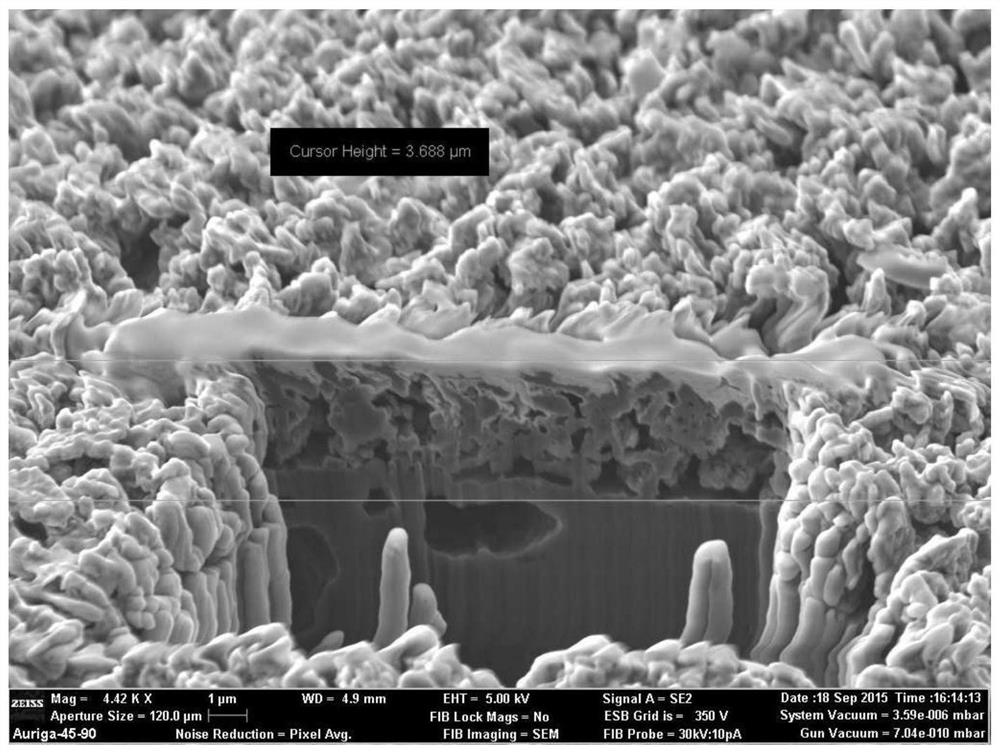

[0094] After the temperature of the substrate dropped to room temperature, the weight was recorded. The weight gain was 3.9g, and the thickness of the resin layer was about 1.5μm in a single increase...

Embodiment 2

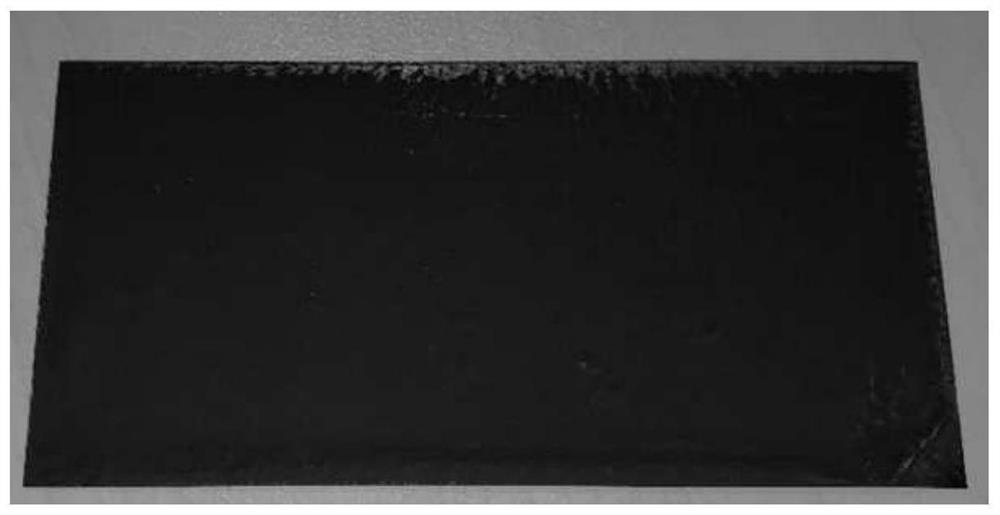

[0106] In this embodiment, we use nano-sized boron powder particles to coat boron on an aluminum substrate with a length of 100 mm and a width of 50 mm to make a new thermal neutron converter. Experiments have proved that when the aluminum substrate is coated with boron, a better surface effect can be obtained by directly coating the boron-containing coating without coating the resin layer.

[0107] The boron coating method includes the following steps:

[0108] i) prepare the substrate, clean the surface, weigh and record;

[0109] ii) Applying a boron-containing coating

[0110] Prepare an appropriate amount of boron-containing resin solution according to the following formula, and mix well.

[0111] Nanoscale boron powder: resin: curing agent: solvent=180:16:4:1000 (weight ratio)

[0112] It is required that the ratio of boron powder: (resin + curing agent) is about 9:1; solute (boron powder + resin + curing agent): solvent is about 1:5.

[0113] Completely immerse the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com