Cyclic sedimentation method and device, and method for producing dry organic fertilizer powder

A settling device and organic fertilizer technology, applied in organic fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of large area, production capacity impact, pipeline blockage, etc., and achieve high removal rate, low cost, and occupation of site area. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

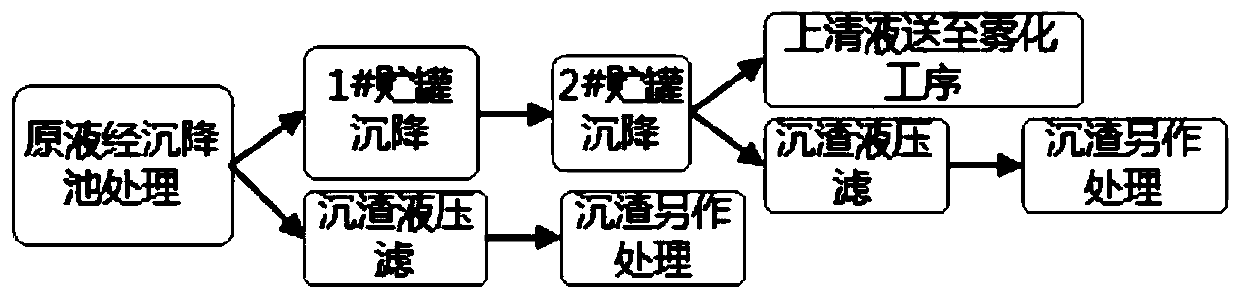

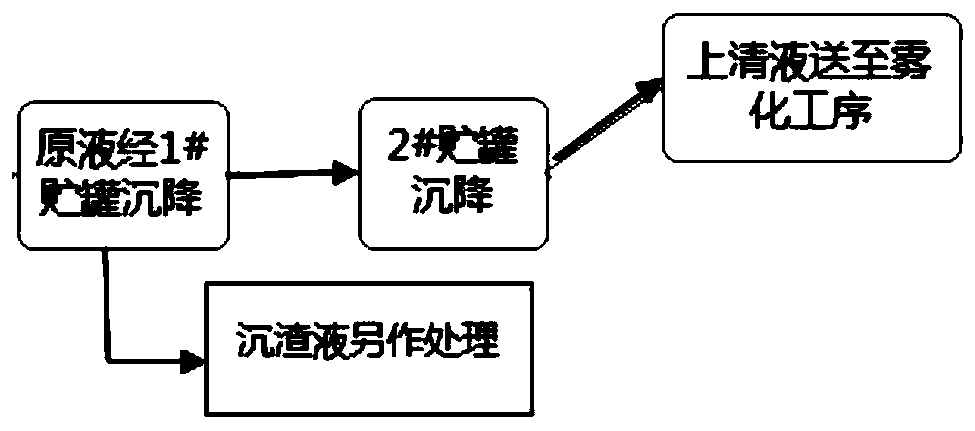

[0050] Factory C has been improved and has Figure 4 The shown circulation sedimentation process equipment of the present invention comprises two storage tanks, a total of about 2400 tons of storage capacity, see Figure 5 An implementation form of the illustrated circulation settling device. Two storage tanks have been adopted to carry out the circulation sedimentation process on the molasses alcoholic fermentation concentrated solution with a Brix of about 60 ° Bx, namely:

[0051] Step 1. Use the molasses alcoholic fermentation concentrate with a Brix of about 60°Bx as the stock solution, add the stock solution to the first storage tank and let stand for 4 hours, then transfer the supernatant of the first storage tank to the second storage tank Let stand for 1 hour;

[0052] Step 2, transfer the stock solution containing sediment and colloid in the lower layer of the second storage tank to the first storage tank and leave it for 5 hours, then transfer the supernatant of t...

Embodiment 2

[0057] Factory C has Figure 4 The shown circulation sedimentation process equipment of the present invention comprises two storage tanks, a total of about 2400 tons of storage capacity, see Figure 5 An implementation form of the illustrated circulation settling device. Two storage tanks have been adopted to carry out the circulation sedimentation process on the molasses alcoholic fermentation concentrated solution with a Brix of about 60 ° Bx, namely:

[0058] Step 1, using the molasses alcoholic fermentation concentrated solution with a Brix of about 60 ° Bx as the stock solution, adding the stock solution to be treated in the first storage tank and standing for 4 hours, then transferring the supernatant of the first storage tank to the second storage tank Stand in the jar for 1 hour;

[0059] Step 2, transfer the bottom layer of the second storage tank to the stock solution containing sediment and colloid in the first storage tank and leave standstill for 5 hours, then t...

Embodiment 3

[0063] Factory C has Figure 4 The shown circulation sedimentation process equipment of the present invention comprises two storage tanks, a total of about 2400 tons of storage capacity, see Figure 5 An implementation form of the illustrated circulation settling device. Two storage tanks have been adopted to carry out the circulation sedimentation process on the molasses alcoholic fermentation concentrated solution with a Brix of about 60 ° Bx, namely:

[0064] Step 1, using the molasses alcoholic fermentation concentrated solution with a Brix of about 60 ° Bx as the stock solution, the stock solution was left to stand for 4 hours in the first storage tank, and then the supernatant of the first storage tank was transferred to the second storage tank to statically set for 1 hour;

[0065] Step 2, in the first storage tank, add new stock solution to be treated (that is, the molasses alcoholic fermentation concentrated liquid that the Brix is about 60°Bx), while the bottom lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com