Wire saw machining center and operation method thereof

An operation method and technology of a machining center, which can be used in work accessories, stone processing equipment, fine work devices, etc., and can solve the problems of inability to process curved slices, troublesome slicing, and limitation of processing slice varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

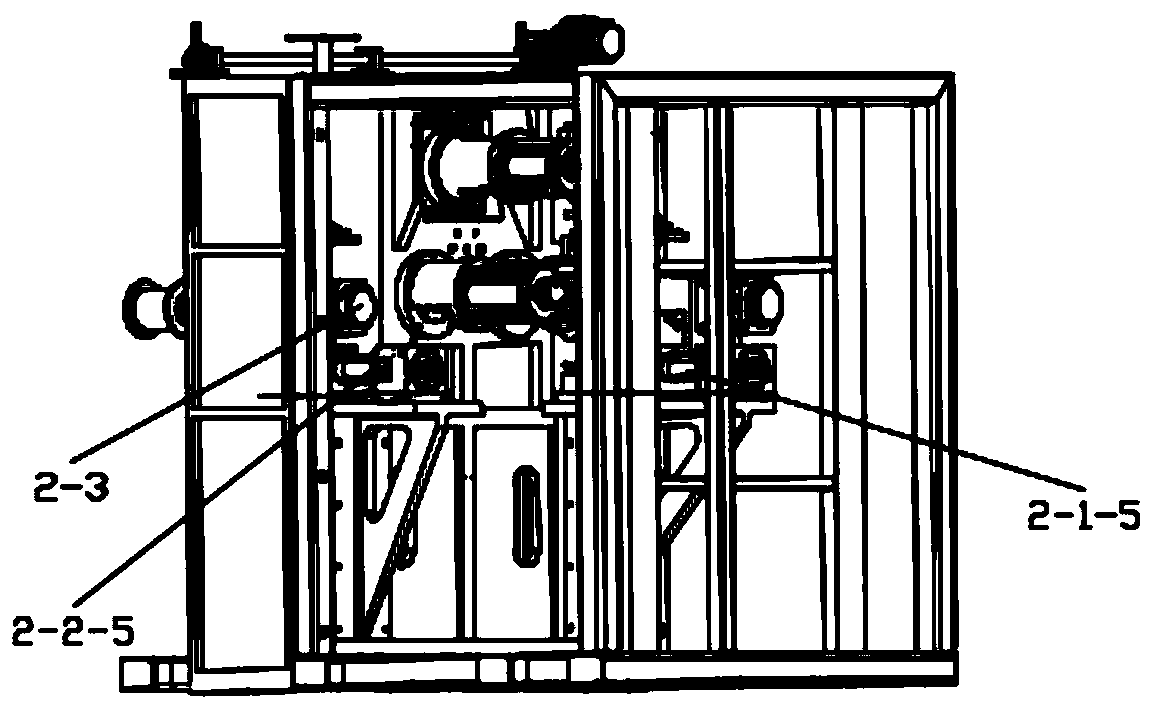

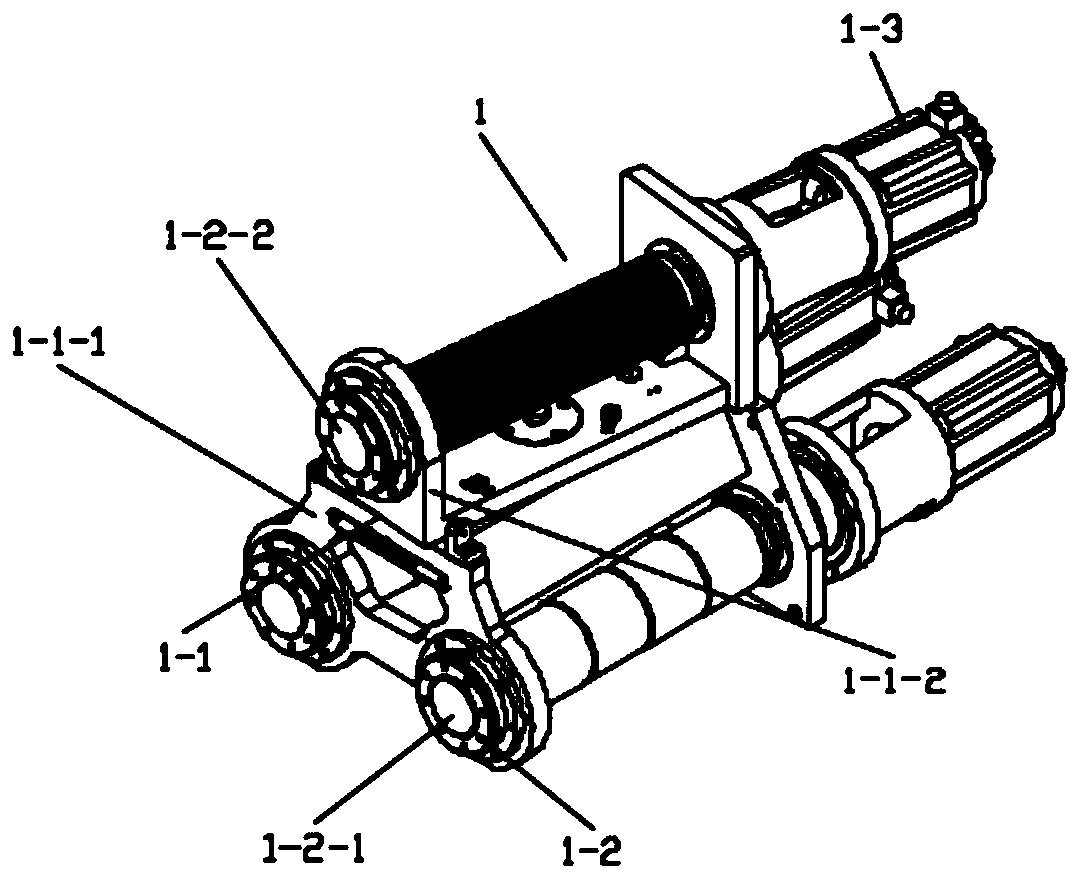

[0152] like Figure 1 to Figure 8As shown, this embodiment provides a wire saw machining center, including a wire saw cutting mechanism 1, a steel wire retracting mechanism 2, and a worktable 3. The wire saw cutting mechanism 1 includes a knife rest 1-1 and a roller 1-2. The knife rest 1-1 is divided into a knife rest lower body 1-1-1 and a knife rest upper body 1-1-2. The lower frame body 1-1-1 and the upper body 1-1-2 of the tool rest are rotatably connected, and the roller 1-2 includes an upper roller 1-2-2 and two lower rollers 1-2-1, one of which is The upper roller 1-2-2 is rotatably connected with the upper body 1-1-2 of the tool rest, and the two lower rollers 1-2-1 are rotatably connected with the lower body 1-1-1 of the tool rest, and two The bottom roller 1-2-1 and one of the top rollers 1-2-2 are respectively driven and connected to the roller servo motor 1-3, the roller 1-2 is wound with a steel wire 0, and the steel wire 0 Reciprocate along the X direction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com