Insulin flexible particles and preparation thereof

A kind of insulin and flexible technology, which is applied in the field of flexible insulin particles and its preparations, can solve the problems of flexibility and hypoglycemic effect, and limit the development and application of insulin non-injection preparations, and achieve high transmucosal transport capacity and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Insulin / phospholipid complex

[0070] Take 60 mg of insulin, feed the mass ratio of insulin: phospholipid according to 1:3, 1:5, 1:10, 1:20, 1:50, and prepare as follows:

[0071]Dissolve 60 mg of insulin in 6 mL of methanol solution containing 0.1% trifluoroacetic acid; dissolve 180 mg, 300 mg, 600 mg, 1200 mg and 3000 mg of soybean lecithin in 54 mL of dichloromethane, and mix the above two solutions to form a clear solution. The solution was rotary evaporated under reduced pressure at 37°C until the solvent was evaporated to dryness, placed in a vacuum oven, dried and then scraped into a closed container to obtain a series of insulin-phospholipid complexes, labeled as complex I, II, III, IV, V.

Embodiment 2

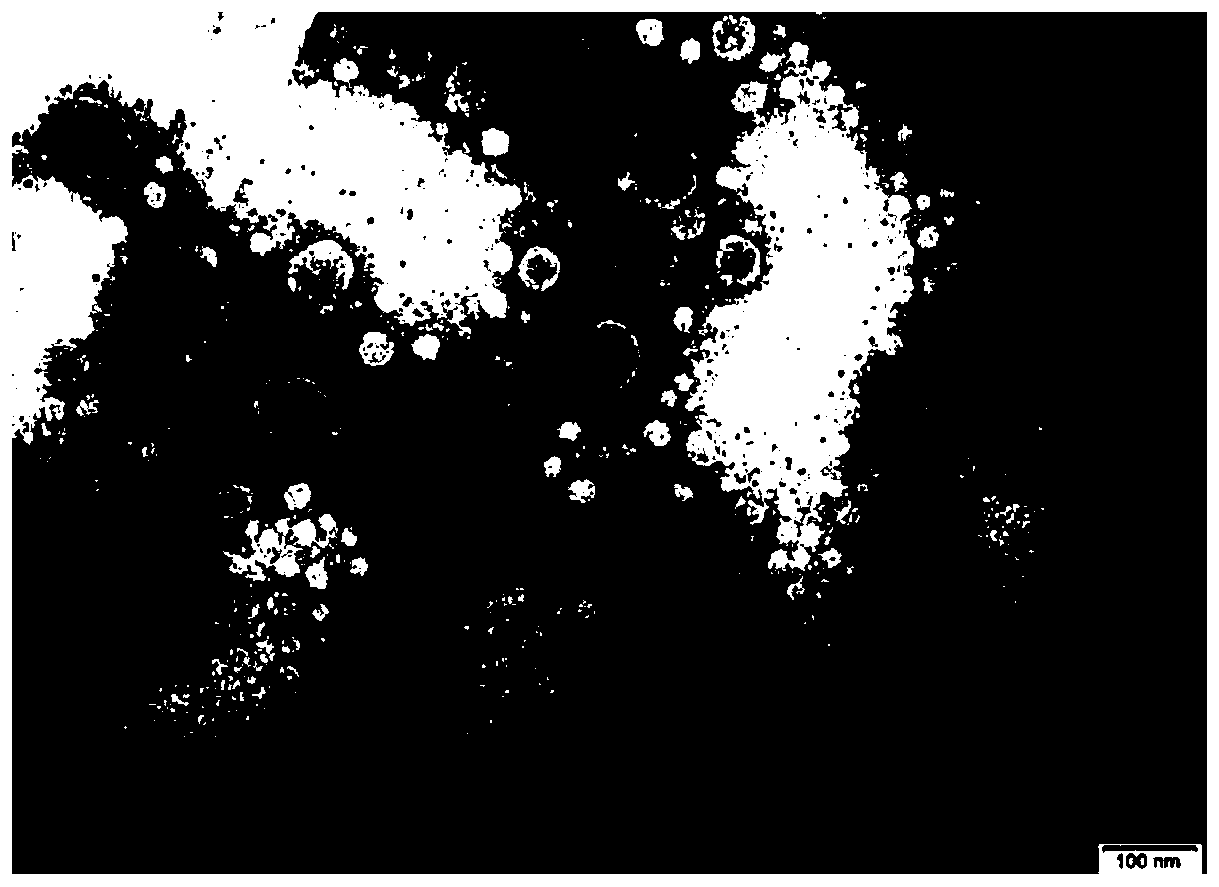

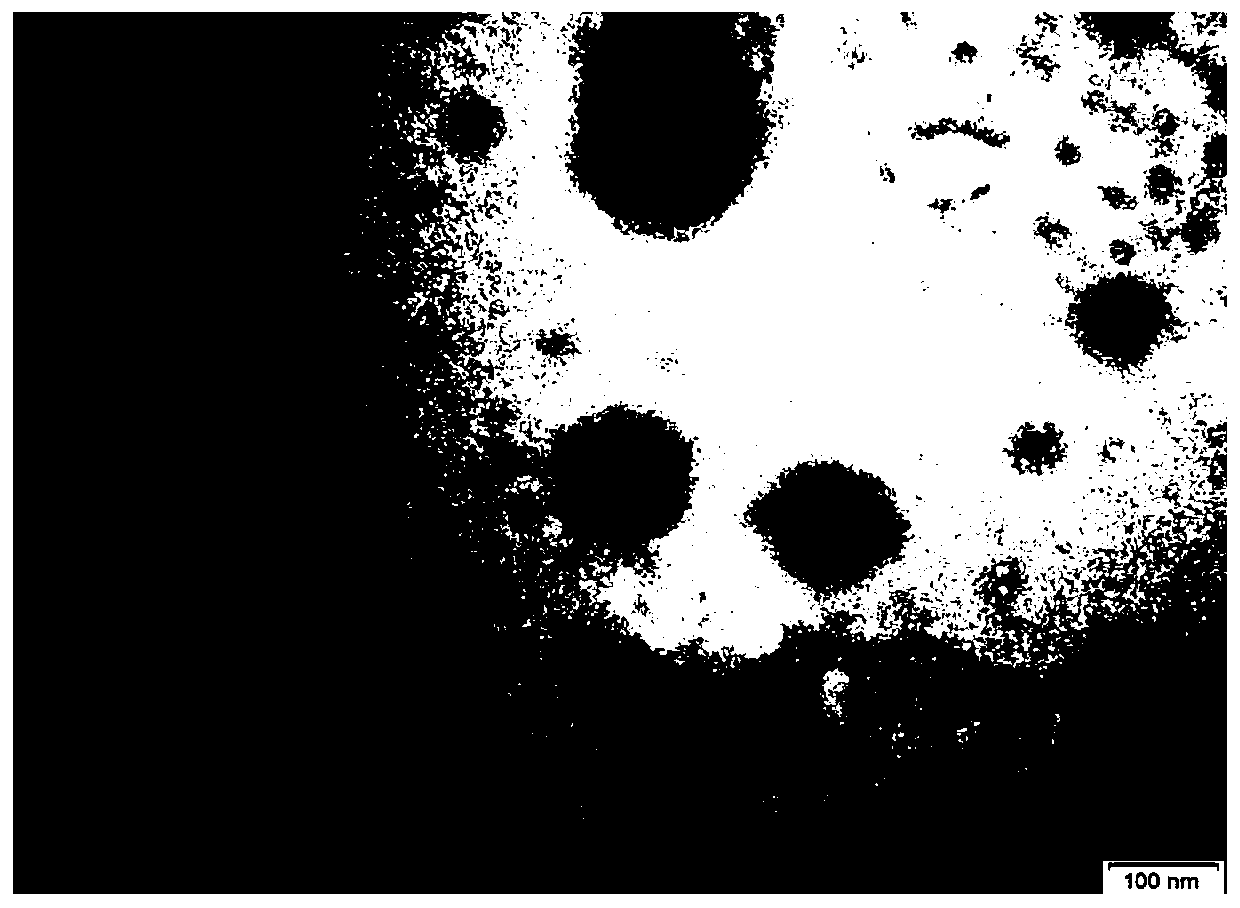

[0072] Example 2: Using insulin / phospholipid complexes as intermediate carriers to prepare flexible insulin particles

[0073] Take 660 mg of insulin / phospholipid complex III prepared in Example 1, and dissolve it together with 400 mg of Tween20 and 100 mg of sodium deoxycholate in 20 ml of a mixed solvent (chloroform:methanol=3:1) to form a clear solution. The solution was rotary evaporated under reduced pressure at 37°C until the solvent evaporated to dryness to obtain a dry film. Use 20mL of phosphate buffer (0.02mol / L) to hydrate the formed film for 30min. After the hydration is completed, the probe is ultrasonically dispersed (150W, 1min / time, 4 times in total) and passed through the membrane (0.22μm) to obtain Flexible microparticles with insulin / phospholipid complexes as intermediate carriers. The particle size measured by the laser particle size analyzer is 80.57±0.68nm, the PDI is 0.268±0.011, the zeta potential is -25.27±0.85mV, the encapsulation rate is 72.06±1.84%...

Embodiment 3

[0075] Example 3: Using insulin / phospholipid complexes as intermediate carriers to prepare flexible insulin particles

[0076] Take 660 mg of insulin / phospholipid complex III prepared in Example 1 and 400 mg of Tween20 and dissolve them together in 20 mL of dichloromethane to form a clear solution. The solution was rotary evaporated under reduced pressure at 37°C until the solvent evaporated to dryness to obtain a dry film. Dissolve 100 mg of sodium deoxycholate in 20 mL of phosphate buffer (0.02 mol / L) to obtain a phosphate buffer of sodium deoxycholate. Use the phosphate buffer solution of sodium deoxycholate to hydrate the formed film for 30 minutes. After the hydration is completed, the probe is ultrasonically dispersed (150W, 1min / time, 4 times in total) and passed through the membrane (0.22μm) to obtain insulin / phospholipid complex is the flexible particle of the intermediate carrier. The particle size measured by the laser particle size analyzer is 84.57±0.65nm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com