Hydraulic vibration damper, in particular for a vehicle chassis

A hydraulic shock absorber and chassis technology, which is applied in the direction of liquid shock absorber, shock absorber, spring/shock absorber functional characteristics, etc., can solve the problems of unfavorable check valve service life and wear, and adverse effects on comfort, etc. Achieving reduced noise levels, improved comfort, and reduced demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the various figures, identical parts are always provided with the same reference numerals and will therefore generally also be referred to or mentioned only once in each case.

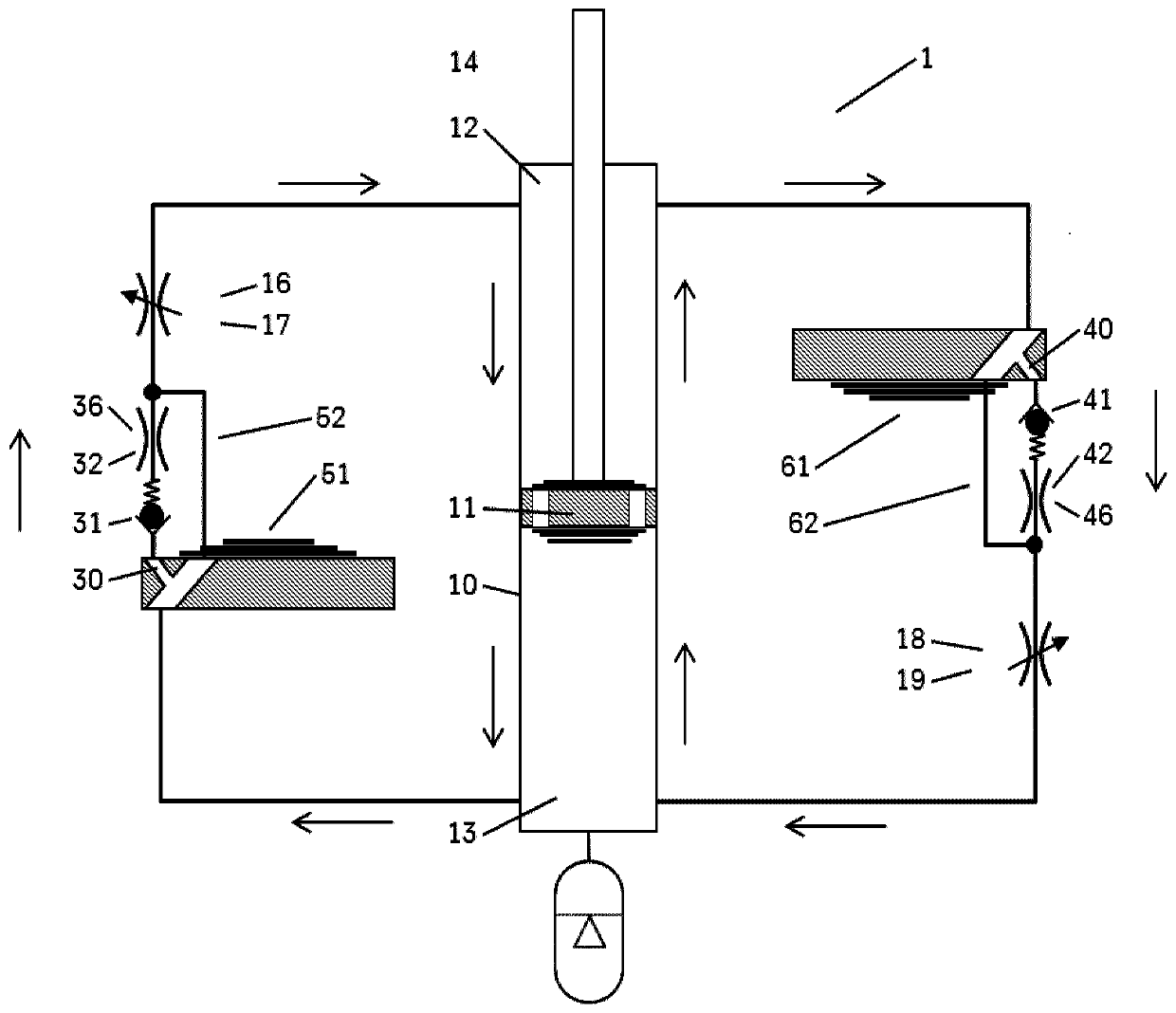

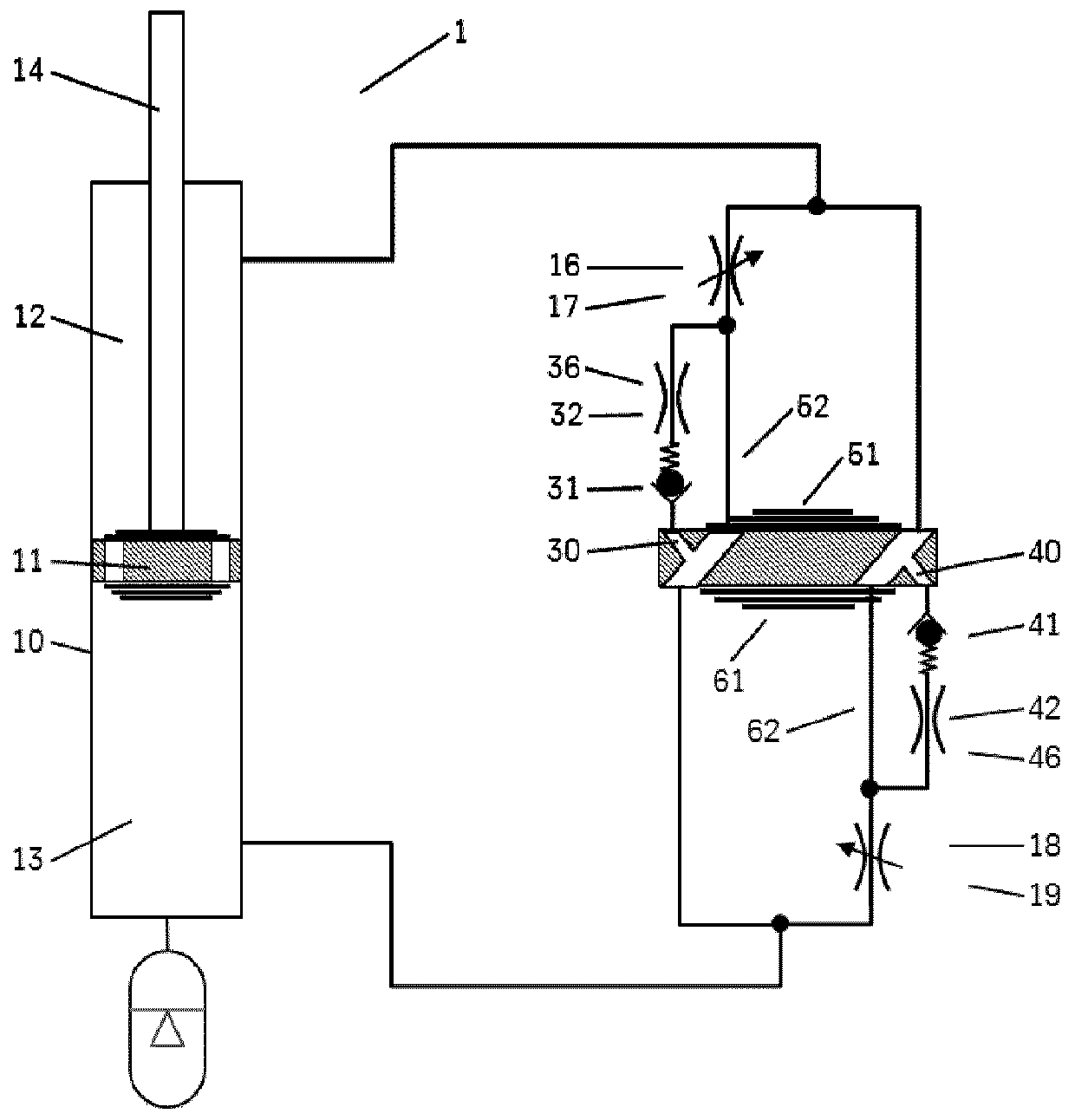

[0039] figure 1 A block diagram showing the hydraulic flow in the shock absorber 1 according to an exemplary embodiment of the present invention. Arrows pointing upwards indicate the direction of flow in the compression phase of the piston 11 , and arrows pointing downwards indicate the direction of flow in the rebound phase of the piston 11 . Piston 11 includes a piston rod 14 and divides cylinder 10 into a first working chamber 12 and a second working chamber 13 . Two sub-ducts 30, 40 of the bypass duct 20 are shown. Here, the sub-pipe 30 includes a check valve 31 connected in series and a throttle valve 32 connected in series as part of a throttle mechanism 36 with said check valve 31 . In this case, the blocking direction of the non-return valve 31 points to the side facing away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com