Tuning peg planting equipment of piano sound source

A peg and sound source technology, which is applied in the field of peg implantation equipment, can solve the problems that the peg axis is not easy to align, affect the sound quality of the piano sound source, and reduce the stability of the peg, so as to optimize the production process, improve the stability, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

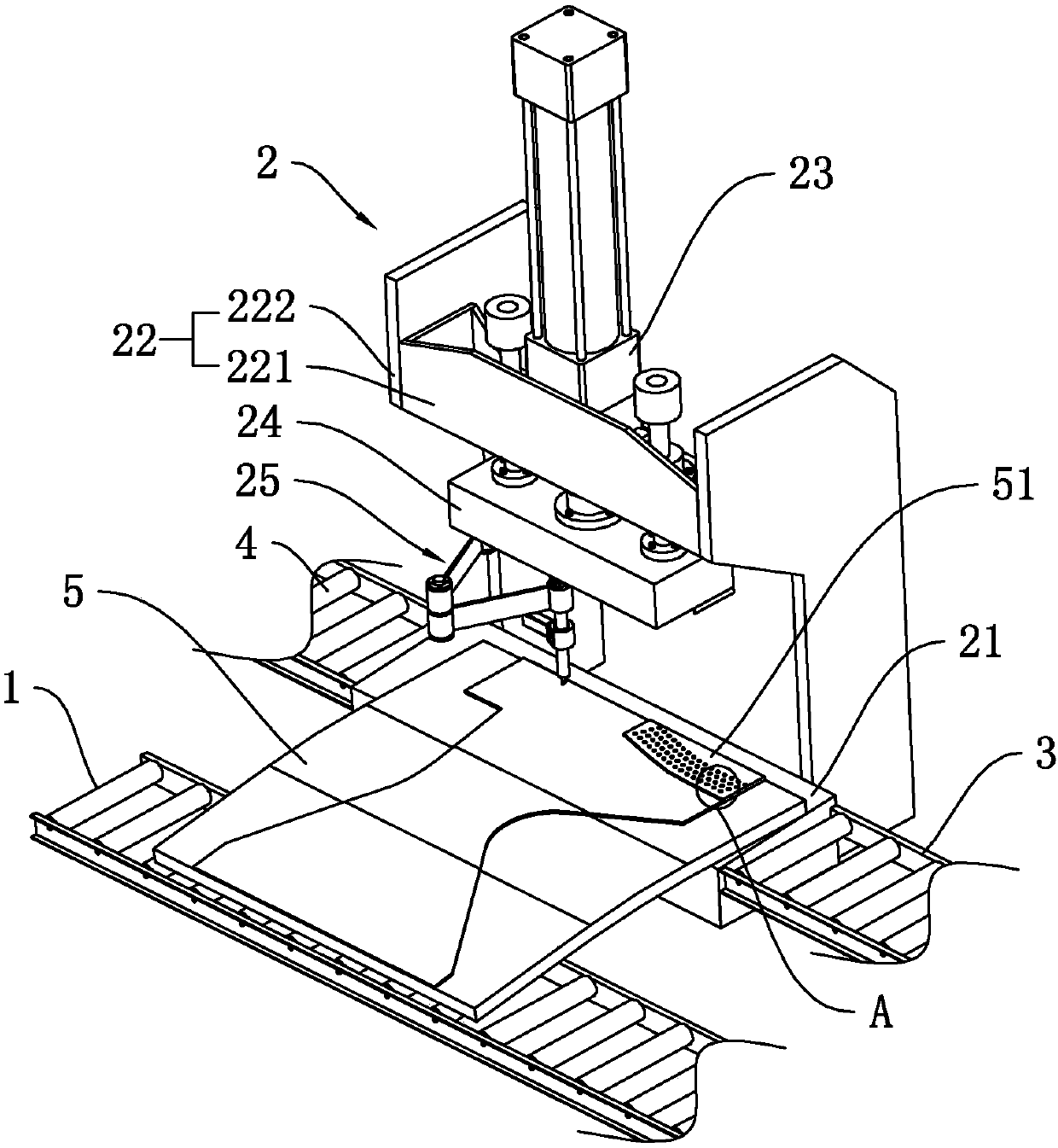

[0055] as attached figure 1 As shown, a peg insertion device for a piano sound source includes a conveying roller belt 1, a peg insertion device 2 located on one side of the conveying roller belt 1, and an entering roller belt 4 and a removing roller belt 3. The peg loading device 2 includes a hanger 22 and a bearing platform 21 , the hanger 22 includes supports 222 on both sides and a mounting platform 221 fixed between the two supports 222 . The pressure bearing platform 21 is fixed on the ground and is located directly below the installation platform 221 , and the length direction of the pressure bearing platform 21 is parallel to the conveying roller belt 1 . The entering roller belt 4 and the removing roller belt 3 are respectively fixed on the two ends of the installation platform 221 in the length direction, and the length direction of the water entering roller belt and the removing roller belt 3 is parallel to the length direction of the delivery roller belt 1 .

[00...

Embodiment 2

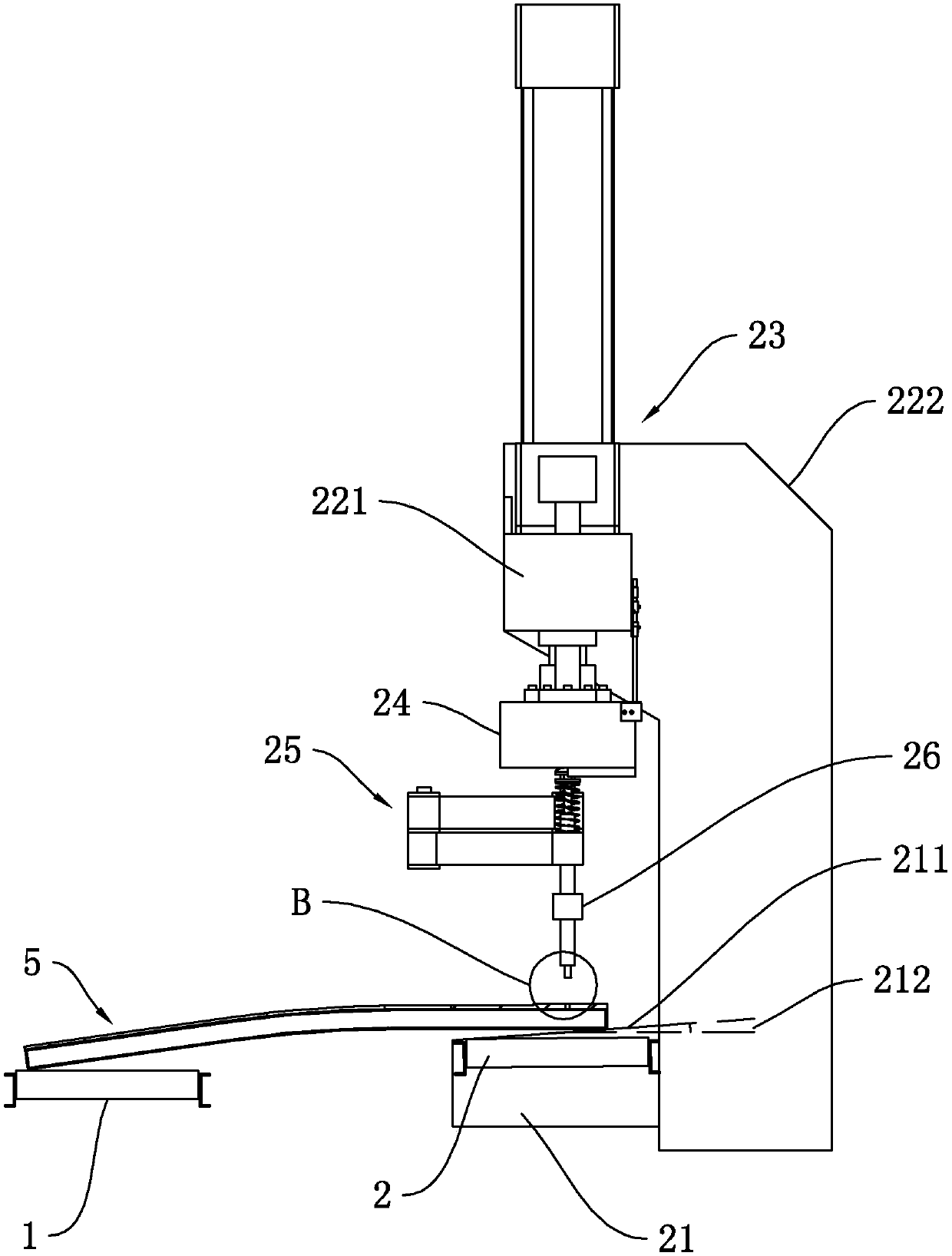

[0085] as attached Figure 12 As shown, a peg insertion device for a piano sound source is improved on the basis of Embodiment 1. A pressure bearing frame 267 is fixed inside the fixing ring 262, and the pressure bearing frame 267 includes two parallel pressure bearing plates 2671 up and down. And several pressure-bearing columns 2672 vertically connecting the outer edges of the two pressure-bearing plates 2671. The mounting column 261 includes an upper column 2612 and a lower column 2613 , the lower end of the upper column 2612 is fixed to the upper surface of the pressure frame 267 , and the upper end of the lower column 2613 is fixed to the lower surface of the pressure frame 267 .

[0086] The shaft loader also includes a rotating drive part 268, which is fixed on the inner wall of the pressure frame 267, and the rotating drive assembly can be determined according to the actual situation, and a micro motor is selected here. There is a rotary switch 2641 on the handle 264,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com