Test method and evaluation method for hydrogen-induced cracking of small-diameter thin-walled pipes

An evaluation method and technology for thin-walled tubes, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as very sensitive crack thickness rate, obvious differences in crack geometric dimensions, and no unified regulations on the definition of crack length and thickness. , to achieve the effect of expanding the scope of inspection and improving the possibility of finding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The test method for hydrogen-induced cracking of small-diameter thin-walled pipes includes the following steps:

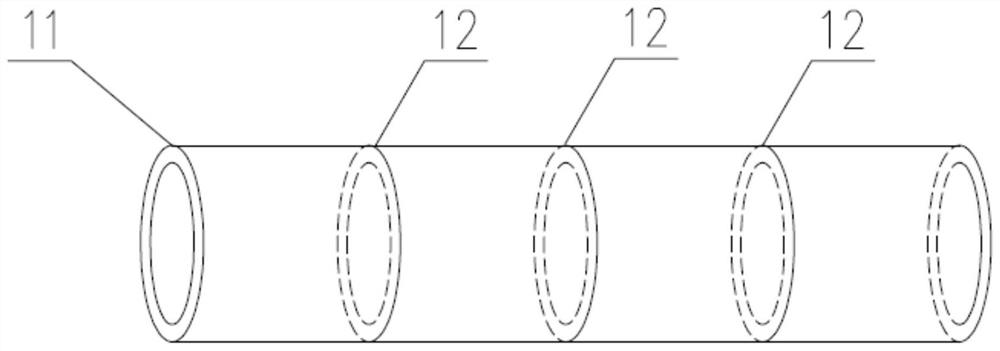

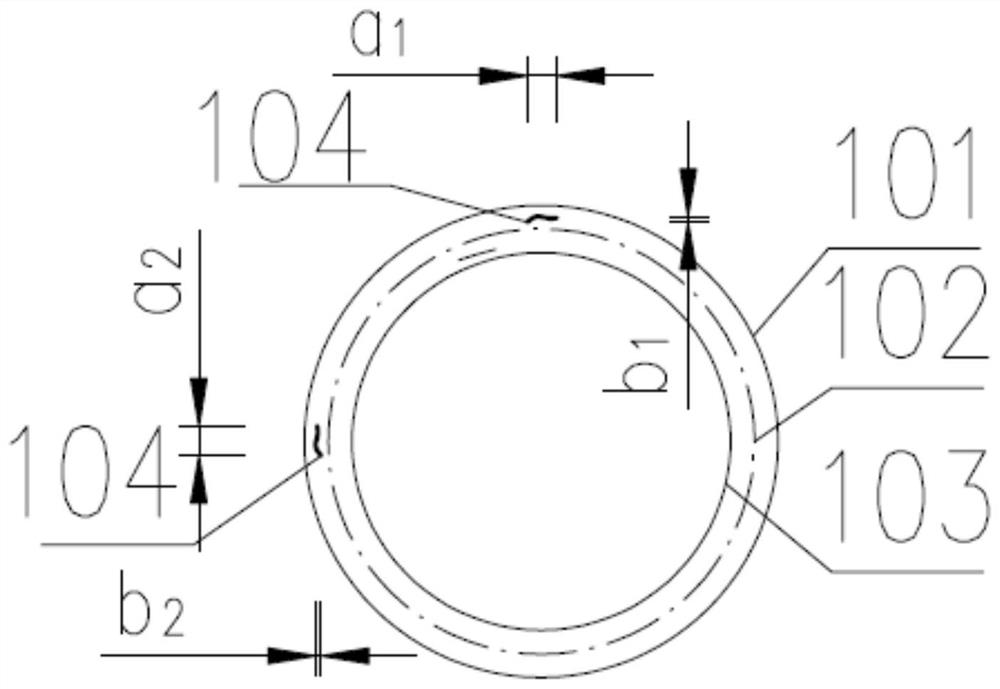

[0035] S1. The small-diameter thin-walled pipe is treated with the outer wall 101 and the inner wall 103 to remove the oxide layer or rust layer, to ensure the set wall thickness of the small-diameter thin-walled pipe, and then cut into three rings with a unit length of 100±1mm along the length direction. The pipe section is used as the original sample pipe; the three samples are respectively labeled as 10(HSC)-HIC-11, 10(HSC)-HIC-12, and 10(HSC)-HIC-13.

[0036] In the scheme, the small-diameter thin-walled pipe adopts 10 (HSC) steel pipe resistant to hydrogen sulfide corrosion. The specification is Φ25*2.5mm. After the inner wall 103 and the outer wall 101 are finished, a pipe section of 100±1 mm is cut, and the length direction is along the rolling direction of the steel pipe. Use 320# sandpaper to grind the surface of the sample in one direction to for...

Embodiment 2

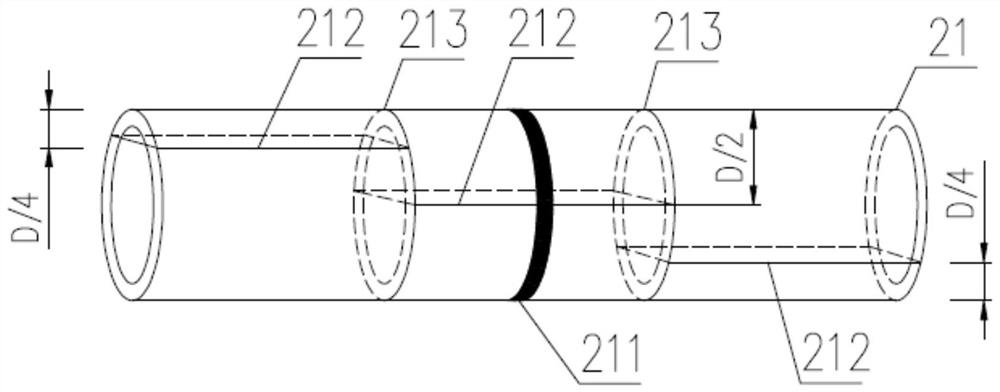

[0066] The difference from Example 1 is that the sample in this example is a circular weld sample 21 . When obtaining the metallographic inspection surface, such as figure 2 As shown, the girth weld sample 21 is divided into three equal sections in the length direction to form three weld sample sub-sections, and the equal section is the sample section 213; each weld sample sub-section is parallel to the axially cut The upper surface is used as the metallographic inspection surface 212 , that is, three metallographic inspection surfaces 212 are obtained. The distance from each metallographic inspection surface 212 to the upper surface of the corresponding weld sample subsection is different. In this embodiment, the distances from the metallographic inspection surface 212 to the upper surface of the corresponding weld sample subsection are D / 4, D / 2, 3D / 4. A total of 9 inspection surfaces were obtained for the three samples, which were respectively labeled as 111, 112, 113, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com