Thermal gas flowmeter and application thereof

A technology of thermal gas flow and gas flow channel, which is applied in the application of thermal effects to detect fluid flow, etc., can solve the problems of large influence by installation conditions and poor measurement accuracy, and achieve no risk of clogging, little influence, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

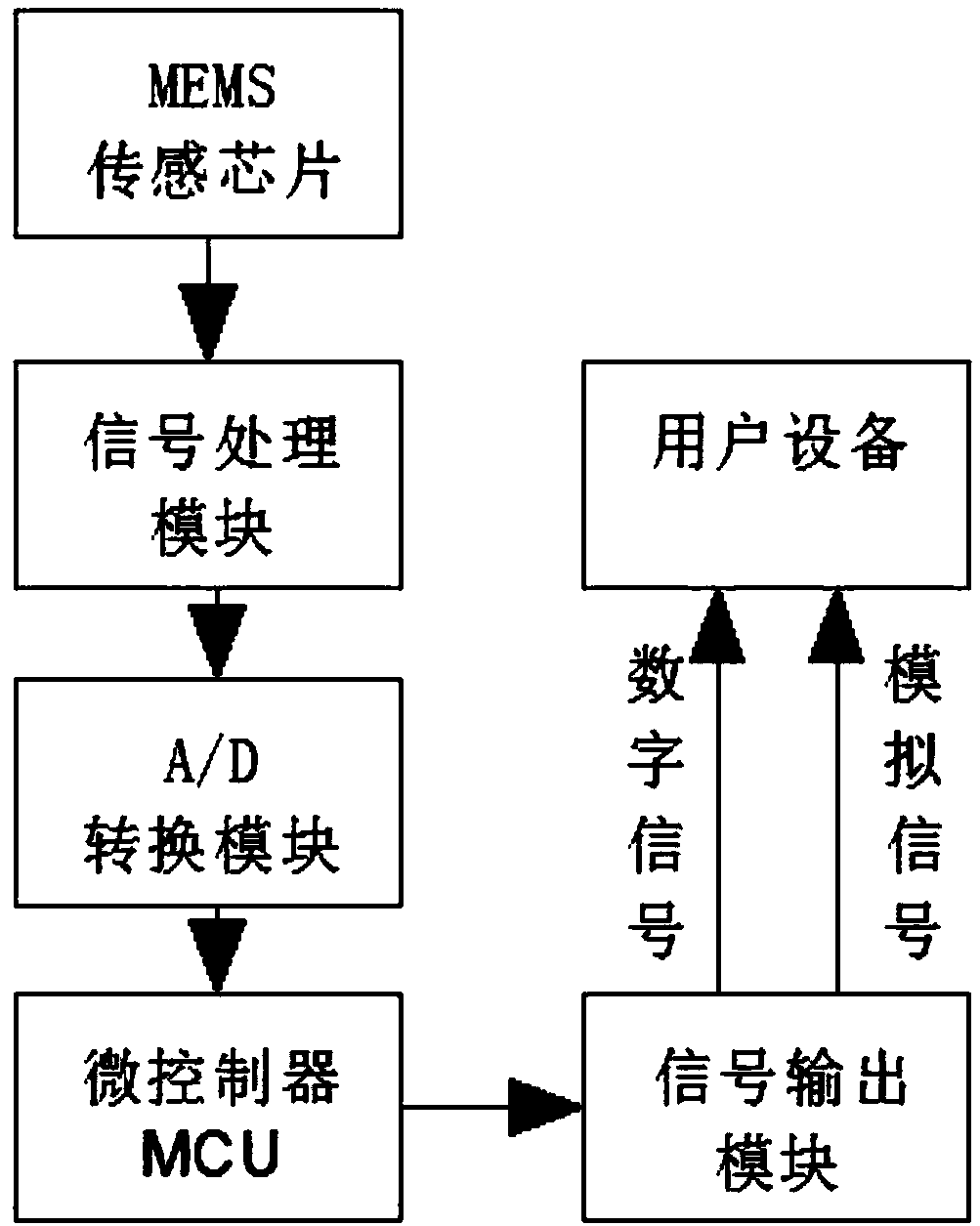

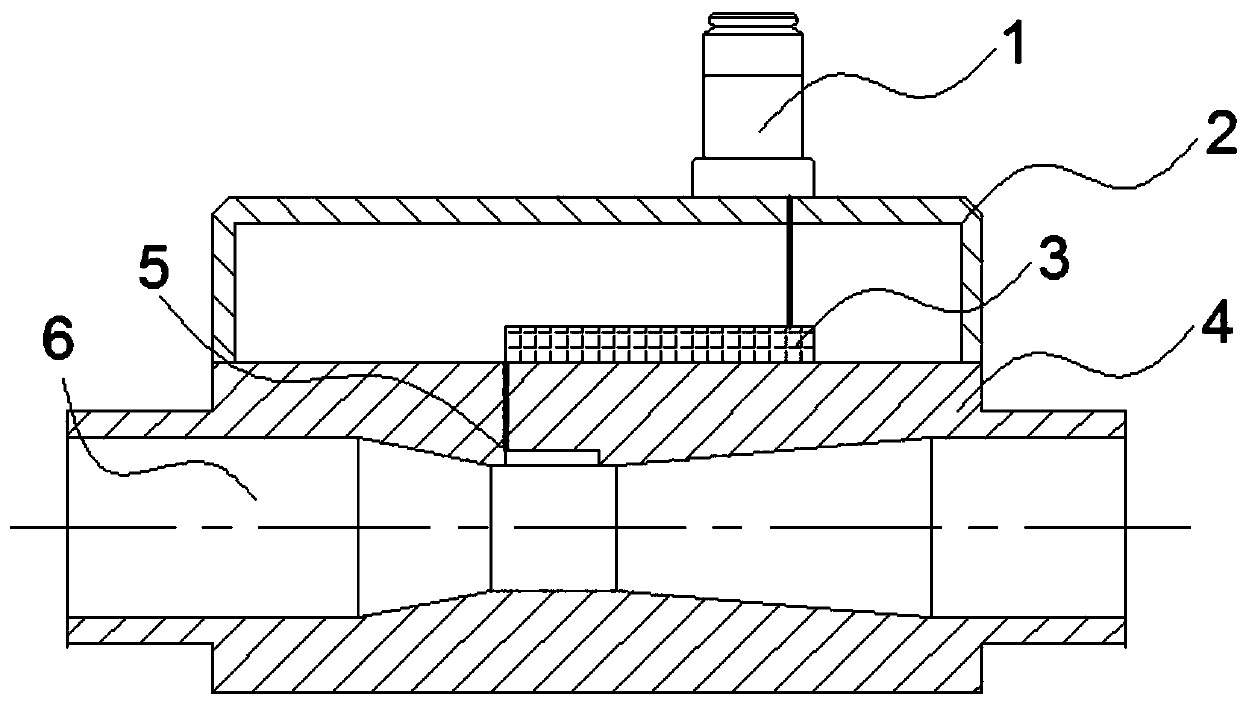

[0025] A thermal gas flow meter such as figure 2 As shown, including aviation plugs, circuit housings, PCB circuits, gas flow channel housings, MEMS hardware systems, and gas flow channels; such as figure 1 As shown, the MEMS hardware system includes a MEMS sensor chip, a signal processing module, an A / D conversion module, a microprocessor MCU, and a signal output module.

[0026] The MEMS chip is embedded in the inner wall of the gas flow channel and connected to the PCB circuit. The PCB circuit is placed in the circuit shell and connected to the aviation plug. The gas flow channel is a Venturi structure.

[0027] The aviation plug is used for power supply and data transmission to the PCB circuit.

[0028] The PCB circuit integrates heat source circuit, bridge circuit, signal adjustment circuit, microcontroller, communication module, etc. Realize the reading, conversion and transmission of MEMS chip data.

[0029] The MEMS sensor chip integrates a heat source unit and a t...

Embodiment 2

[0037] A thermal gas flow meter such as figure 2 As shown, including aviation plugs, circuit housings, PCB circuits, gas flow channel housings, MEMS hardware systems, and gas flow channels; such as figure 1 As shown, the MEMS hardware system includes a MEMS sensor chip, a signal processing module, an A / D conversion module, a microprocessor MCU, and a signal output module.

[0038] The MEMS chip is embedded in the inner wall of the gas flow channel and connected to the PCB circuit. The PCB circuit is placed in the circuit shell and connected to the aviation plug. The gas flow channel is a Venturi structure.

[0039] The aviation plug is used for power supply and data transmission to the PCB circuit.

[0040] The PCB circuit integrates heat source circuit, bridge circuit, signal adjustment circuit, microcontroller, communication module, etc. Realize the reading, conversion and transmission of MEMS chip data.

[0041] The MEMS sensor chip integrates a heat source unit and a t...

Embodiment 3

[0049] A thermal gas flow meter such as figure 2 As shown, including aviation plugs, circuit housings, PCB circuits, gas flow channel housings, MEMS hardware systems, and gas flow channels; such as figure 1 As shown, the MEMS hardware system includes a MEMS sensor chip, a signal processing module, an A / D conversion module, a microprocessor MCU, and a signal output module.

[0050] The MEMS chip is embedded in the inner wall of the gas flow channel and connected to the PCB circuit. The PCB circuit is placed in the circuit shell and connected to the aviation plug. The gas flow channel is a Venturi structure.

[0051] The aviation plug is used for power supply and data transmission to the PCB circuit.

[0052] The PCB circuit integrates heat source circuit, bridge circuit, signal adjustment circuit, microcontroller, communication module, etc. Realize the reading, conversion and transmission of MEMS chip data.

[0053] The MEMS sensor chip integrates a heat source unit and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com