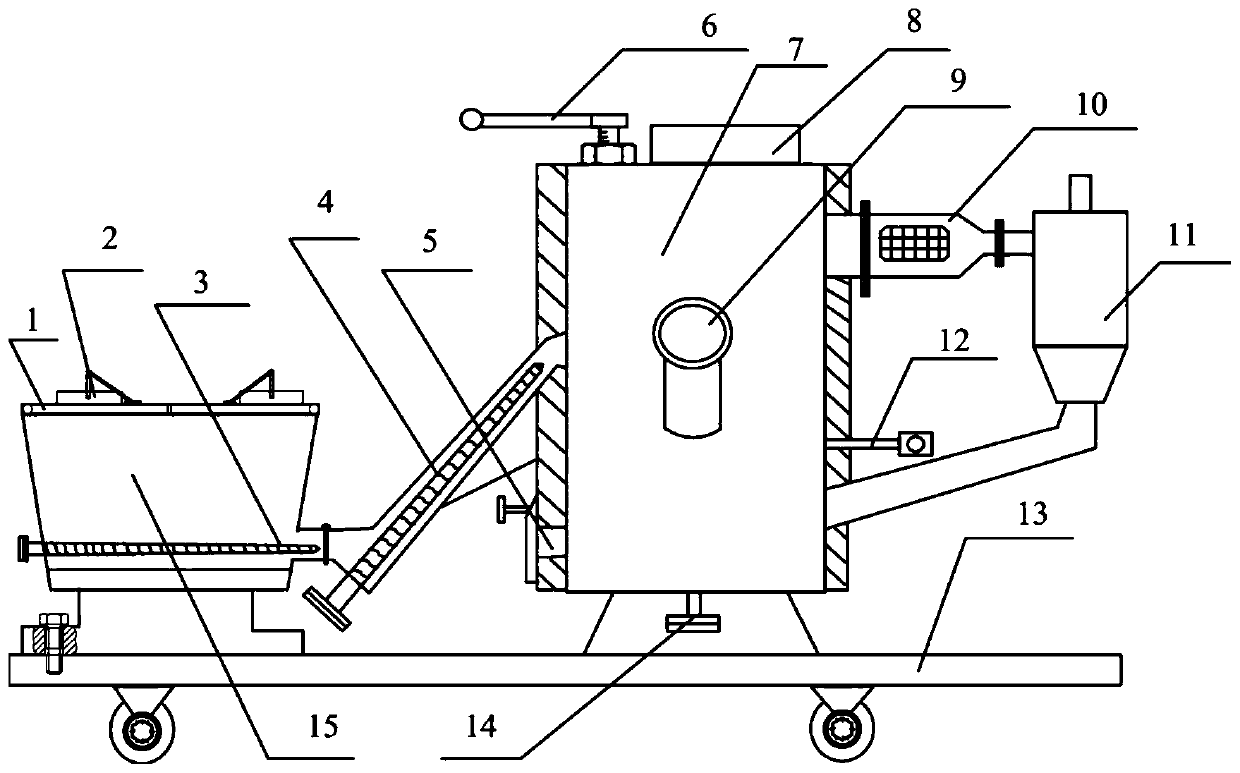

Inclined feeding type agricultural and forestry biomass particle combustion furnace

A biomass combustion furnace and biomass technology, which is applied in the combustion, combustion method, combustion equipment and other directions of solid fuel, can solve problems such as incompatibility, achieve sufficient combustion, ensure personal and property safety, and save manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

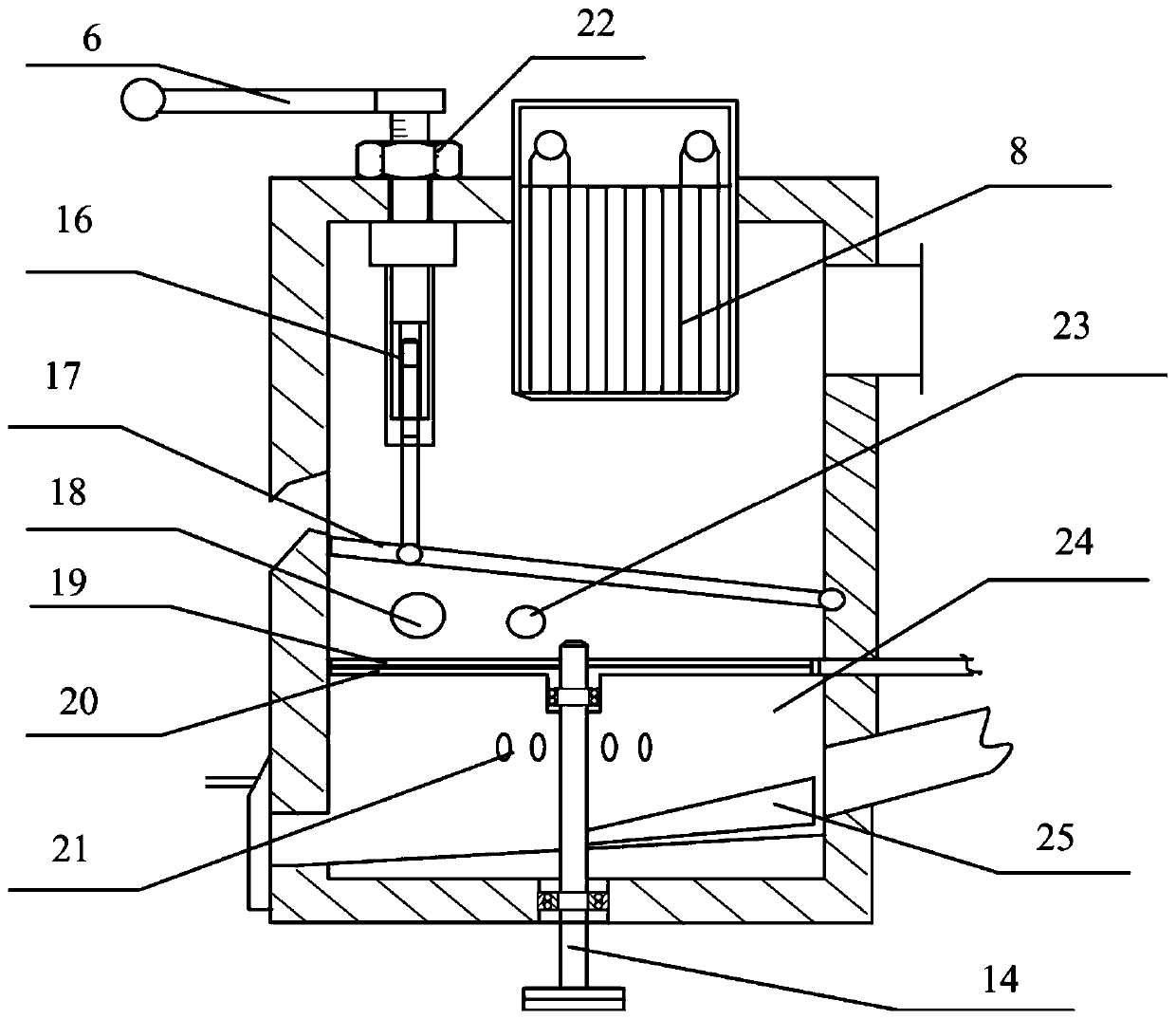

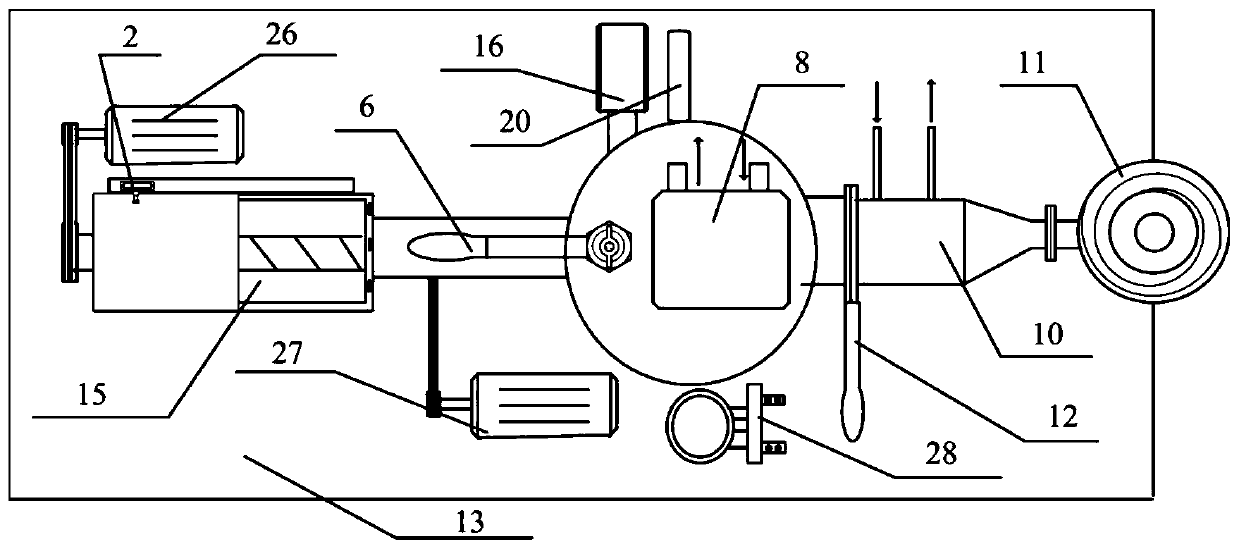

Method used

Image

Examples

Embodiment 2

[0073] A rural family adopts the present invention to heat the family room. The family has indoor heating equipment. Here, the heat exchanger 8 in the furnace of the present invention is directly connected to the interface of the original heating equipment. The heat exchange outside the furnace and the waste heat utilization device 10 Connect the hot water insulation tank of the family to provide domestic hot water. And the feeding bin 15 is slightly lower than the ground, and the bulk biomass material can be easily poured into the bin. Due to factors such as capital and site, the tail gas purification device 11 is not used, and the control system is not used in the whole process. It is to realize the function of automatic feeding and automatic ash discharge. The ash falls into a large container slightly below the ash outlet and is manually cleaned the next day.

[0074] The biomass scraps mainly burned are corn stalks, wheat straws, and the mixture of the above scraps and co...

Embodiment 3

[0076] A grain drying enterprise adopts the patent of the present invention as the energy supply device, and sends the air preheated by the heat exchange and waste heat utilization device 10 outside the furnace into the biomass combustion furnace through the fan 18, mainly preheating the cold air, and passing it through the fan 18. It is passed into the furnace, and the air required for combustion is preheated to achieve the purpose of energy saving. At this time, all the systems mentioned in the present invention are adopted, including the control system and the detection system. And it is integrated into the control cabinet with its drying system. At this time, the circulating medium in the heat exchanger 8 in the furnace is the heat carrier air of the drying box. A cyclone dust collector, that is, an exhaust gas purification device 11, is arranged to remove dust from the flue gas and discharge it into the atmosphere. At the same time, the temperature sensor is arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com