Heavy-load high-temperature self-lubricating rolling bearing and processing technology

A high-temperature self-lubricating, rolling bearing technology, applied in the mechanical field, can solve problems such as easy failure, damage, and high noise, and achieve the effect of improving safety and stability and ensuring lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

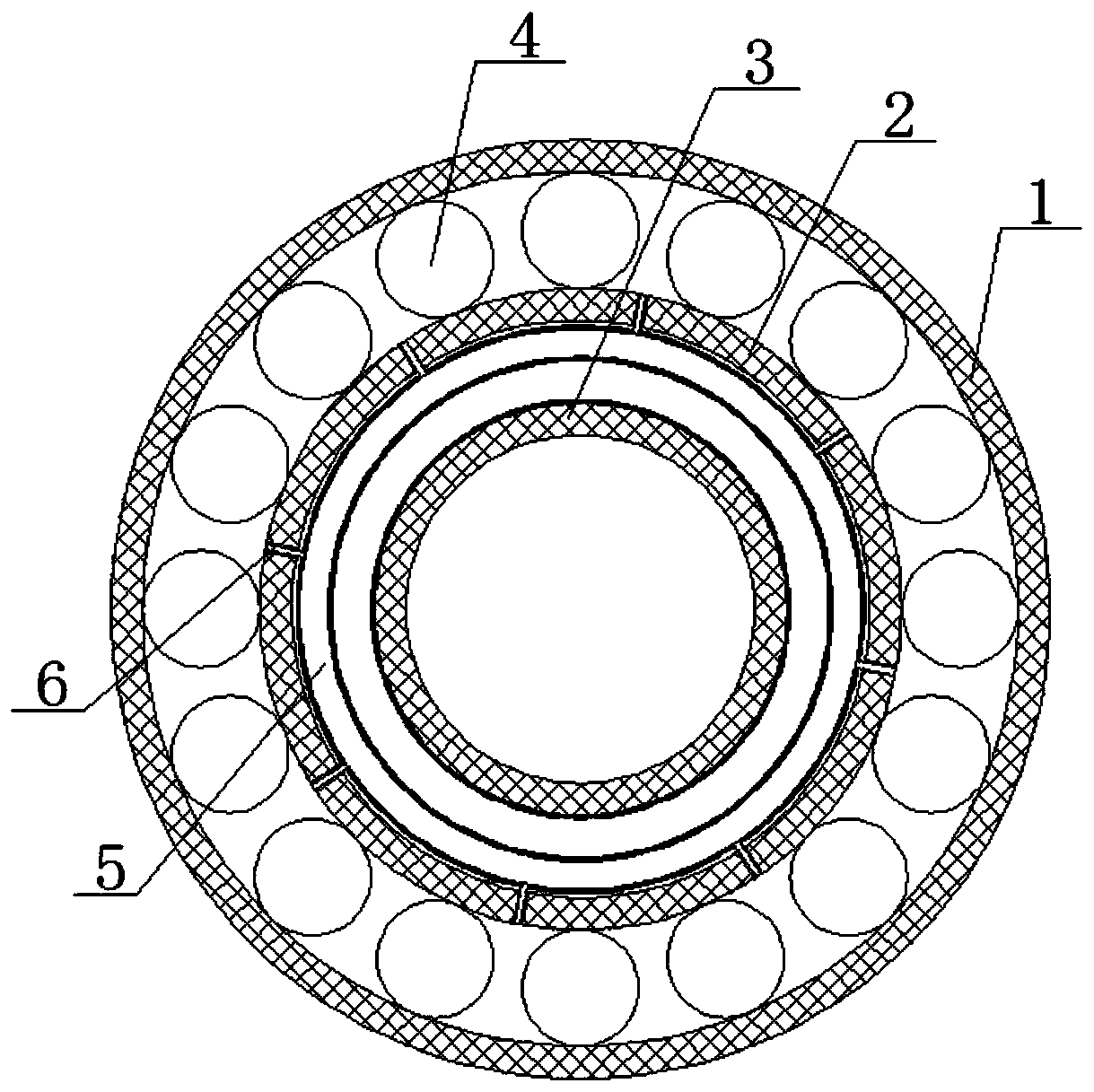

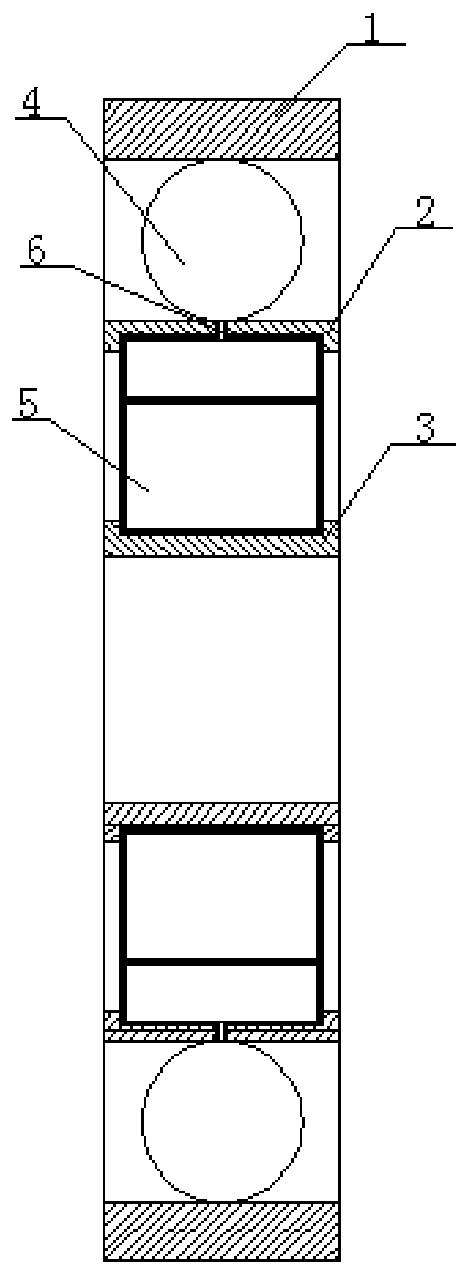

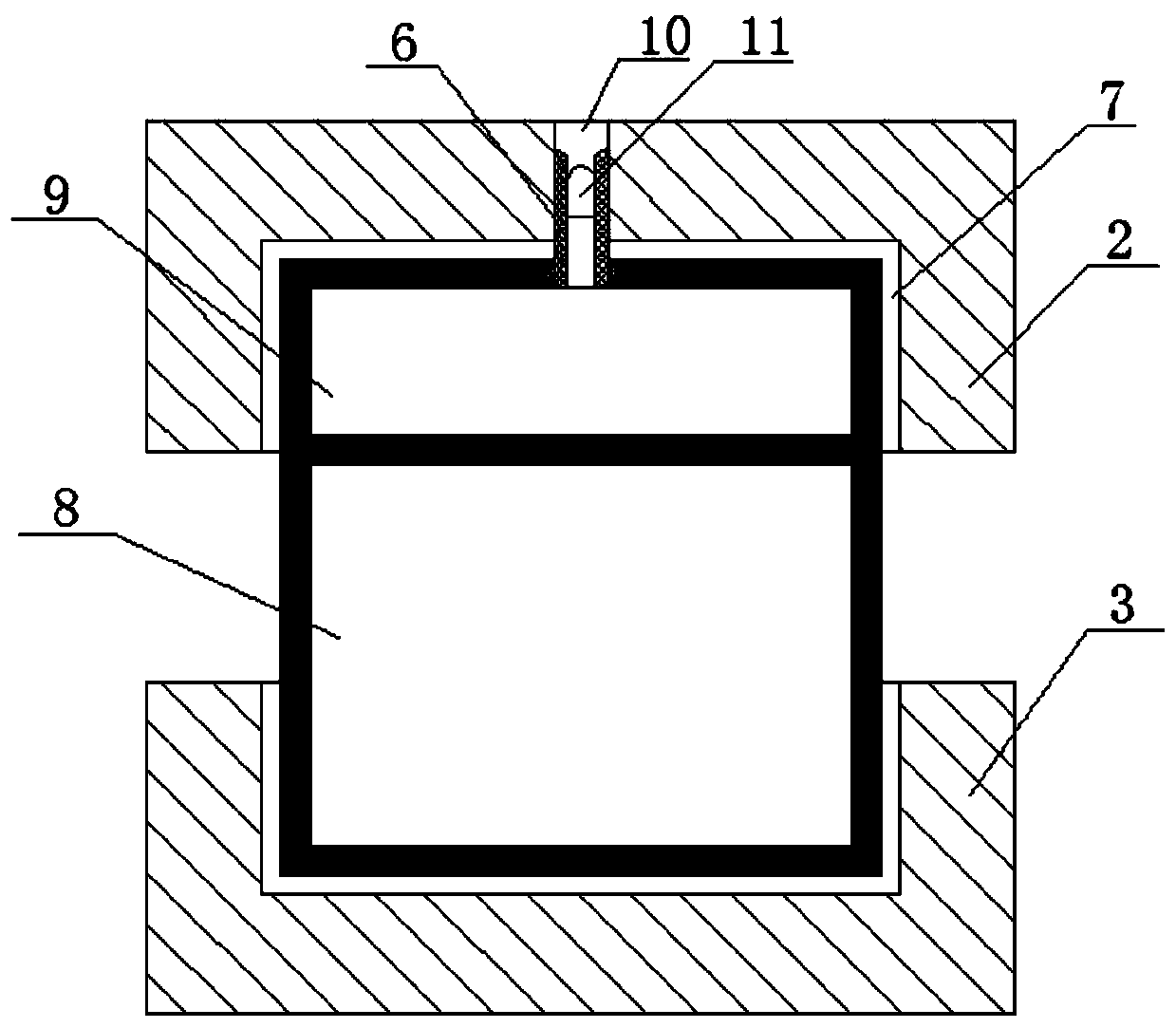

[0034] Such as figure 1 and figure 2 The heavy-duty high-temperature self-lubricating rolling bearing shown includes an inner ring 3, an outer ring 1, and an intermediate ring 2 arranged between the inner ring 3 and the outer ring 1, and the inner ring 3, the intermediate ring 2, and the outer ring 1 concentrically, a ball set 4 is provided between the middle ring 2 and the outer ring 1, the outer ring 1 rotates relative to the middle ring 2 according to the ball set 4, the middle ring 2 is fixedly connected with the inner ring 3, and the A lubricating cavity is formed between the intermediate ring 2 and the inner ring 3, and a lubricant extruding device 5 is arranged in the lubricating cavity, and the lubricant extruding device 5 communicates with the lubricant spout 10 penetrating the intermediate ring 2, and the lubricating agent When the lubricant extruding device 5 is heated, the lubricant extruding device 5 extrudes the lubricant in the lubricant extruding device 5 to ...

Embodiment 2

[0043] On the basis of Example 1, in order to seal the bearing, avoid falling dust, and at the same time ensure its heat dissipation, such as Figure 5 and Figure 6 A seal ring 16 is fixed between the two sides of the outer ring 1 and the middle ring 2, and an annular channel 19 concentric with the center of the seal ring 16 is arranged in the seal ring 16. The two seal rings 16 The side is respectively provided with a plurality of inner holes 18 and outer holes 17 extending into the seal ring 16. The inner holes 18 and outer holes 17 communicate with the annular channel 19, and the inner holes 18 and outer holes 17 are arranged in a staggered manner. The sealing ring 16 is also provided with a fixing hole 20 passing through the sealing ring 16 . The inner hole 18 is located on the inner side, and the heat generated will enter the annular channel 19 through the inner hole to increase its heat conduction surface, and at the same time, the heat entering the annular channel wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com