Pre-oxidized fiber core spun yarn and manufacturing method thereof

A manufacturing method and technology of pre-oxygenated filaments, which are applied in the directions of yarn, textile and papermaking, conjugated synthetic polymer rayon, etc., can solve the problems of low mechanical strength of preoxygenated filaments, less application of preoxygenated filaments, and unsuitable skin contact. , to achieve excellent thermal insulation effect, suitable textile processing performance, improve wear resistance and wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

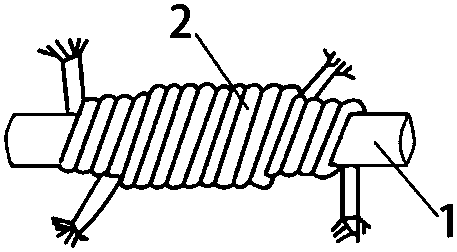

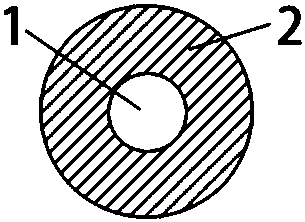

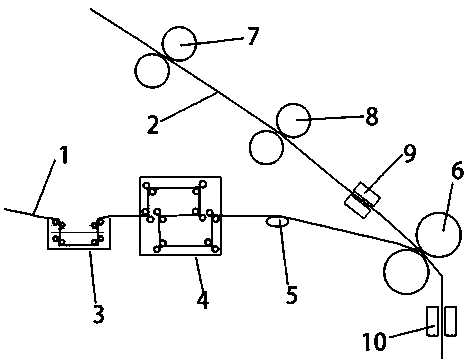

[0032] Refer to attached Figure 1-3 , this embodiment provides a kind of manufacture method of pre-oxidized silk core-spun yarn, comprises the following steps:

[0033] S1. Put 5 kg of ordinary polyacrylonitrile resin with an isotacticity of 20% and 2 kg of high isotactic polyacrylonitrile resin with 45% isotacticity into a high-speed mixer and stir and mix for 10 hours to obtain a mixed resin.

[0034] S2. Add 5kg of the above-mentioned mixed resin and 12kg of dimethylformamide into the reactor, and control the temperature of the reactor to rise to 200°C at a constant speed within 2 hours, so that the mixed resin and dimethylformamide are kept at a constant temperature of 200°C After continuous stirring and mixing for 4 hours under the same conditions, the reaction kettle is vacuumed and degassed, and then the mixed materials are filtered to obtain the spinning stock solution.

[0035] S3. First use the dry-wet spinning technology to process the spinning stock solution thro...

Embodiment 2

[0039] Refer to attached Figure 1-3 , this embodiment provides a kind of manufacture method of pre-oxidized silk core-spun yarn, comprises the following steps:

[0040] S1. Put 5 kg of ordinary polyacrylonitrile resin with an isotacticity of 10% and 4 kg of high isotactic polyacrylonitrile resin with a isotacticity of 55% into a high-speed mixer and mix for 10 hours to obtain a mixed resin.

[0041] S2. Add 5kg of the above mixed resin and 15kg of dimethylformamide into the reactor, and control the temperature of the reactor to rise to 250°C at a constant speed within 2 hours, so that the mixed resin and dimethylformamide are kept at a constant temperature of 250°C After continuous stirring and mixing for 4 hours under the same conditions, the reaction kettle is vacuumed and degassed, and then the mixed materials are filtered to obtain the spinning stock solution.

[0042] S3. First use the dry-wet spinning technology to process the spinning stock solution through the screw ...

Embodiment 3

[0046] Refer to attached Figure 1-3 , this embodiment provides a kind of manufacture method of pre-oxidized silk core-spun yarn, comprises the following steps:

[0047] S1. Putting 5 kg of ordinary polyacrylonitrile resin with an isotacticity of 5% and 3 kg of high isotactic polyacrylonitrile resin of 50% into a high-speed mixer and stirring and mixing for 10 hours to obtain a mixed resin.

[0048] S2. Add 5kg of the above-mentioned mixed resin and 12kg of dimethylformamide into the reactor, and control the temperature of the reactor to rise to 200°C at a constant speed within 2 hours, so that the mixed resin and dimethylformamide are kept at a constant temperature of 200°C After continuous stirring and mixing for 4 hours under the same conditions, the reaction kettle is vacuumed and degassed, and then the mixed materials are filtered to obtain the spinning stock solution.

[0049] S3. First use the dry and wet spinning technology to process the spinning stock solution throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com