Three-dimensional graphene foam/natural polysaccharide-based hydrogel composite scaffold and its preparation method

A graphene foam, natural polysaccharide technology, applied in general culture methods, biochemical equipment and methods, cell culture supports/coatings, etc., can solve the problem of maintaining three-dimensional structural integrity, spatial discontinuity, insufficient flexibility, etc. problem, to achieve the effect of good conductivity, less defects and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

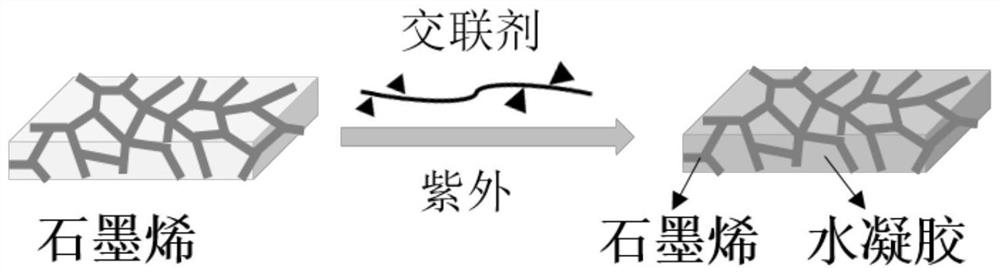

[0023] Another aspect of the embodiment of the present invention also provides a preparation method of a three-dimensional graphene foam / natural polysaccharide-based hydrogel composite scaffold, comprising:

[0024] Provide three-dimensional graphene foam;

[0025] Double bond modification is performed on the natural polysaccharide to obtain a natural polysaccharide cross-linking agent;

[0026] And, the natural polysaccharide cross-linking agent and the photoinitiator are mixed and added to the three-dimensional graphene foam, and reacted under ultraviolet light to obtain the three-dimensional graphene foam / natural polysaccharide-based hydrogel composite scaffold.

[0027] Further, the natural polysaccharide includes any one of glucan, hyaluronic acid, chitosan, and laminarin, and is not limited thereto.

[0028] Further, the molecular weight of the laminarin is 5k-500k, and the modification degree is 10%-80%.

[0029] Further, the photoinitiator includes, but is not limite...

Embodiment 1

[0044] Example 1: Preparation of three-dimensional graphene foam / laminarin-based hydrogel composite scaffold

[0045] (1) three-dimensional graphene foam is prepared by chemical vapor deposition;

[0046](2) Weigh 400 mg of laminarin, add 4 mL of dimethyl sulfoxide, 66.8 mg of 4-lutidine, and 250 mg of glycidyl methacrylate in sequence under nitrogen protection, and stir until completely dissolved. The mixed solution was stirred at room temperature in the dark for 48 h; an equimolar amount of concentrated hydrochloric acid solution was added to neutralize the 4-lutidine in the solution to terminate the reaction. The mixed solution after the reaction was dialyzed with deionized water for 5 days (molecular weight cut-off was 3.5k), and the laminarin cross-linking agent of double bond modification was obtained by freeze-drying, and the reaction was as follows:

[0047]

[0048] Among them, the molecular weight of laminarin is 5k-500k.

[0049] (3) Mix the obtained laminarin ...

Embodiment 2

[0057] Example 2: Preparation of three-dimensional graphene foam / laminarin-based hydrogel composite scaffold

[0058] (1) three-dimensional graphene foam is prepared by chemical vapor deposition;

[0059] (2) Weigh 200 mg of laminarin, add 2 mL of dimethyl sulfoxide, 33.4 mg of 4-lutidine, and 125 mg of glycidyl methacrylate in sequence under nitrogen protection, and stir until completely dissolved. The mixed solution was stirred at room temperature in the dark for 30 h; an equimolar amount of concentrated hydrochloric acid solution was added to neutralize the 4-lutidine in the solution to terminate the reaction. The reacted mixed solution was dialyzed with deionized water for 4 days (molecular weight cut-off was 2k), and lyophilized to obtain a double bond-modified laminarin cross-linking agent, wherein the molecular weight of laminarin was 5k-500k.

[0060] (3) Mix the obtained laminarin cross-linking agent with 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone uniformly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com