Building garbage concrete-brick mixed self-repairing concrete and preparation method thereof

A self-healing, concrete technology, applied in the field of intelligent building materials, can solve problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment includes the following steps:

[0042] Recycled coarse aggregate and recycled brick aggregate are obtained from residential or commercial construction waste:

[0043] (1) Regenerated coarse aggregate and recycled brick aggregate are crushed stone and brick crushed by a jaw crusher, and the sieved particle size is 5-15mm;

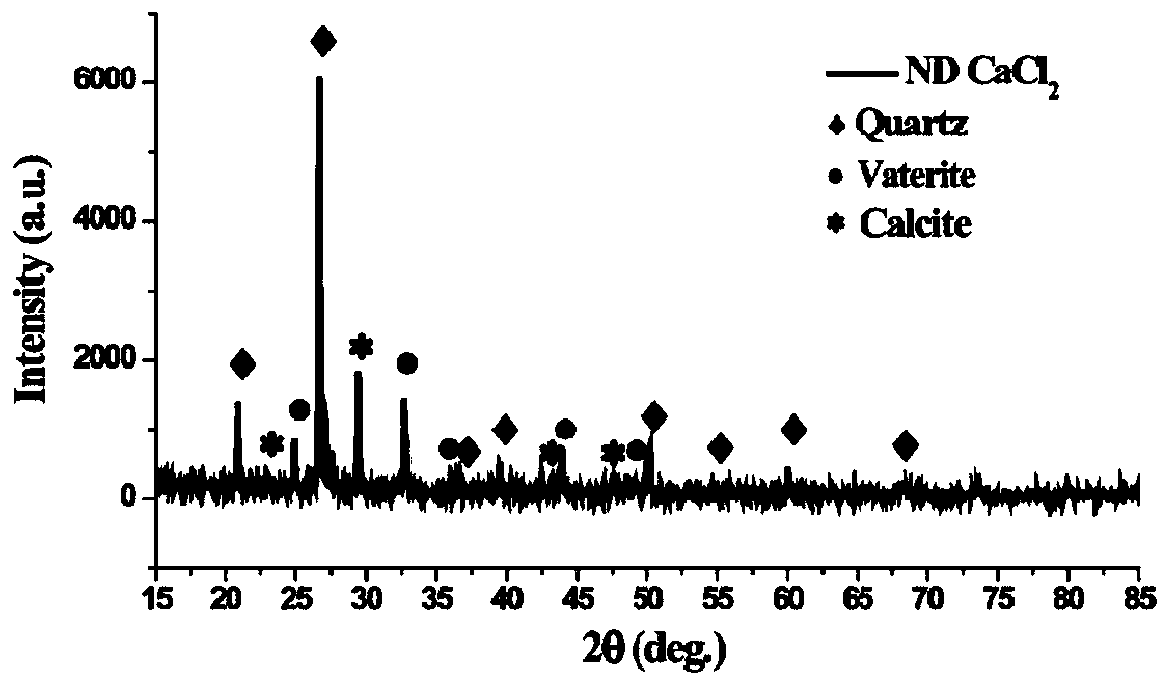

[0044] (2) Bacillus Pasteurella was purchased from Shaanxi Provincial Institute of Microbiology. The microbial culture medium was cultured according to the conventional culture method, with a pH value of 7, shake culture for 12 hours, and place it at low temperature (0-4°C) for 12 hours before vacuum impregnation. Hours later, the bacterial solution was diluted to an OD value of 1.3, and the concentration of Bacillus pasteurianus was 10 10 cell / mL. The microbial culture medium is composed of organic protein mixed with sodium carbonate solution and sodium bicarbonate solution. The mass ratio of organic protein and inorganic sodium sal...

Embodiment 2

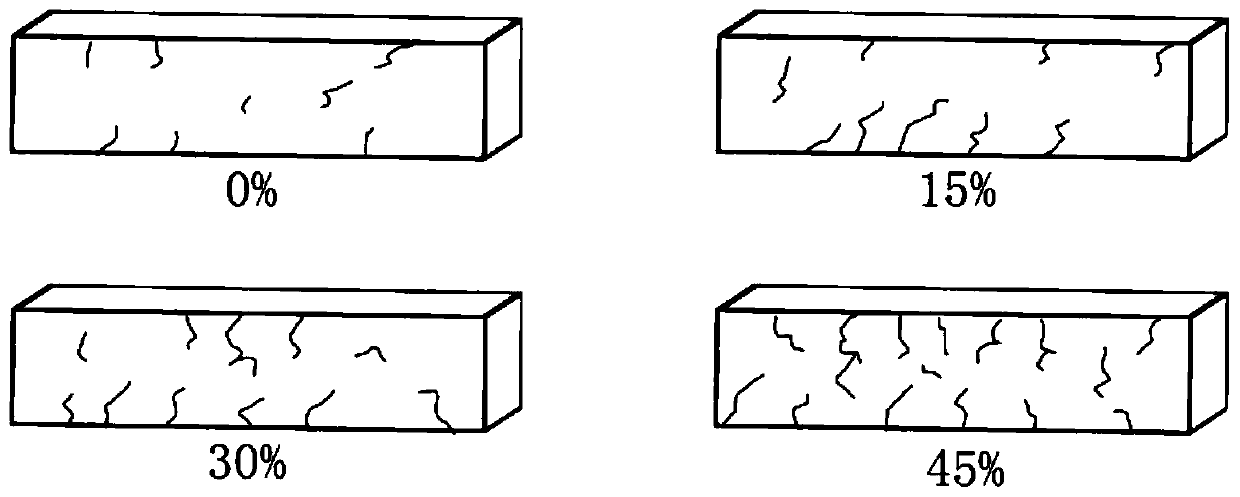

[0050] This embodiment provides a self-repairing concrete mixed with concrete and bricks in construction waste, wherein the mass ratio of water, cement, sand and stone is 0.41:1.00:1.14:2.94.

[0051] The preparation method of the concrete-brick mixed self-repairing concrete is basically the same as that of Example 1; the difference is that the total volume of the self-repairing recycled concrete-brick mixture accounts for 15% of the raw materials for self-repairing concrete preparation.

Embodiment 3

[0053] This embodiment provides a self-repairing concrete mixed with concrete and bricks in construction waste, wherein the mass ratio of water, cement, sand and stone is 0.41:1.00:1.14:2.80.

[0054] The preparation method of the above-mentioned concrete-brick mixed self-repairing concrete is basically the same as that of Example 1; the difference is that the total volume of the self-repairing recycled concrete-brick mixture accounts for 45% of the raw materials for preparing the self-repairing concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com