Method for recovering crude oil in petroleum oil sludge and comprehensively recycling residual mud and sand

A technology for resource utilization and sludge, applied in chemical instruments and methods, petroleum industry, sludge treatment, etc., can solve the problems of secondary air pollution, coking combustion of sludge, waste of resources, etc., to avoid waste, reduce viscosity, and make full use of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

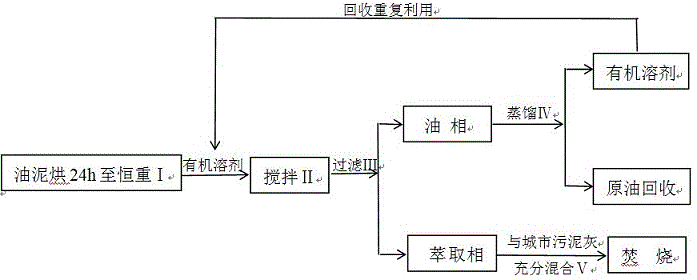

[0032] A method for recovering crude oil in petrochemical sludge and utilizing mud and sand resources, the steps of which are:

[0033] (1) Pretreatment of petrochemical sludge (I), bake the sludge at 105°C for 24 hours to constant weight, and measure its calorific value. Described oil sludge uses oxygen bomb type calorimeter to measure its calorific value, and concrete steps are as follows:

[0034] ① Fill the outer barrel with water (about 18kg);

[0035] ② Weighing: Weigh a certain quality sample (accurate to 0.0002g) and put it into a combustion dish;

[0036] ③ Install the ignition wire: put the oxygen bomb cover on the bullet bracket, take an ignition wire about 10cm long, put the ignition wire in good contact with the sample, and hang the two ends on two ignition wire rods with diagonal seams (one of the rods is also a combustion dish bracket), and lock it with a small locking sleeve;

[0037] ④ Oxygenation: Add 10ml of distilled water into the oxygen bomb, tighten t...

Embodiment 2

[0045] A method for recovering crude oil in petrochemical sludge and utilizing mud and sand resources, the steps of which are:

[0046] A. Mix 10g of oil sludge with 80g of 1,2-dichloroethane, and stir at 40°C for 10min at a speed of 20r / s.

[0047] B. Filtrate for 20 minutes after stirring, recover the organic solvent by distillation, and obtain the separated crude oil at the same time;

[0048]C. The oil sludge in the raffinate phase is fully mixed with the municipal sludge ash at a ratio of 1:2. The experiment can be obtained: the recovery rate of organic solvent is 96%, the recovery rate of crude oil is 43%, the calorific value of the remaining sludge is 24111J / g, and the calorific value of the mixed sludge is 7929J / g.

[0049] Other steps are the same as in Example 1.

Embodiment 3

[0051] A method for recovering crude oil in petrochemical sludge and utilizing mud and sand resources, the steps of which are:

[0052] A. Mix 10g of oil sludge with 80g of ethyl acetate, and stir at 35°C for 10min at a speed of 20r / s.

[0053] B. Filtrate for 20 minutes after stirring, recover the organic solvent by distillation, and obtain the separated crude oil at the same time;

[0054] C. The oil sludge in the raffinate phase is fully mixed with the municipal sludge ash at a ratio of 1:2. The experiment can be obtained: the recovery rate of organic solvent is 95%, the recovery rate of crude oil is 52%, the calorific value of the remaining sludge is 21643J / g, and the calorific value of the mixed sludge is 8192.3J / g.

[0055] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com