A kind of treatment method of hazardous solid waste oil sludge

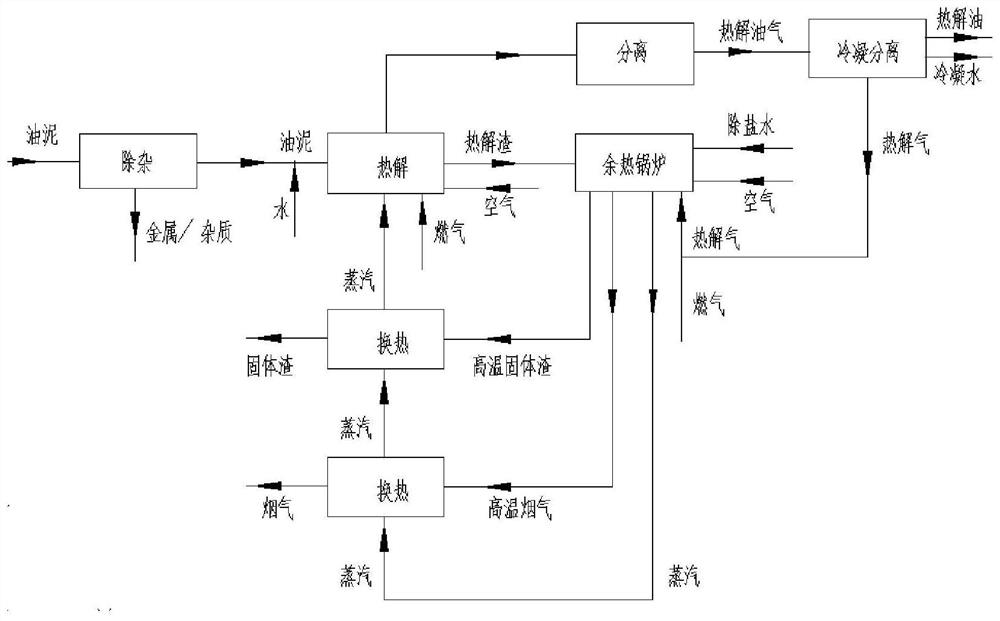

A treatment method and technology of oil sludge, which is applied in the direction of pyrolysis treatment of sludge, petroleum industry, energy input, etc., can solve the problems of increasing solid or organic pollution, ineffective use of pyrolysis oil, treatment, etc., and simplifies the pretreatment process of oil sludge , easy to control, flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

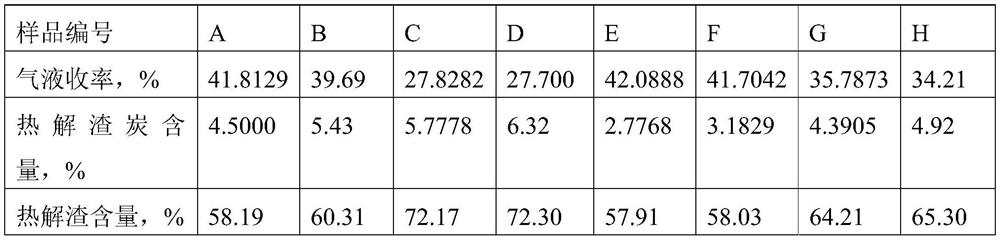

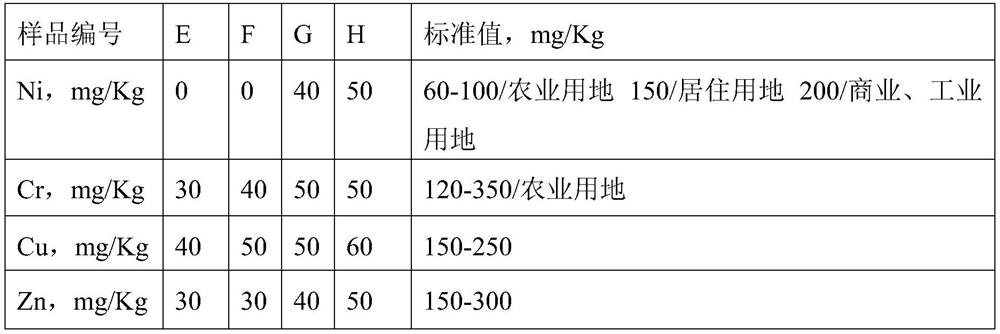

Embodiment 1

[0070] Weigh 43g of oil sludge 1 and place it in a pyrolyzer. According to the method of the present invention, a steam flow rate of 0.5L / min is introduced, and it is pyrolyzed at 550°C and 10kPa for 35min. The pyrolysis slag is sampled and analyzed, and then decarbonized by high-temperature combustion. Pyrolysis oil gas is collected and measured through condensation and separation. The obtained sample number is E, and the evaluation of the pyrolysis performance of the oil sludge is shown in Table 2. The correlation analysis of pyrolysis slag after combustion is shown in Table 3.

Embodiment 2

[0072] Weigh 52g of oil sludge 1 and place it in a pyrolyzer. According to the method of the present invention, a steam flow rate of 0.7L / min is introduced, and it is pyrolyzed at 600°C and 30kPa for 50min. The pyrolysis slag is sampled and analyzed, and then decarbonized by high-temperature combustion. Pyrolysis oil gas is collected and measured through condensation and separation. The obtained sample number is F, and the evaluation of the pyrolysis performance of the oil sludge is shown in Table 2. The correlation analysis of pyrolysis slag after combustion is shown in Table 3.

Embodiment 3

[0074] Weigh 46g of oil sludge 2 and place it in the pyrolyzer, feed steam flow rate 0.6L / min and water flow rate 0.1L / min according to the method of the present invention, and pyrolyze it at 550°C and 20kPa for 40min, and the pyrolysis slag is subjected to high temperature after sampling and analysis. Combustion to remove carbon. Pyrolysis oil gas is collected and measured through condensation and separation. The obtained sample number is G. The evaluation of the sludge pyrolysis performance is shown in Table 2. The correlation analysis of pyrolysis slag after combustion is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com