A treatment method for waste tires based on pyrolysis

A technology for waste tires and treatment methods, which is applied in the direction of products, reagents, educts, etc., can solve the problem of being unable to maintain the rubber expansion state for a long time, and achieve the effects of speeding up the process, speeding up uniform mixing, and optimizing the pyrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

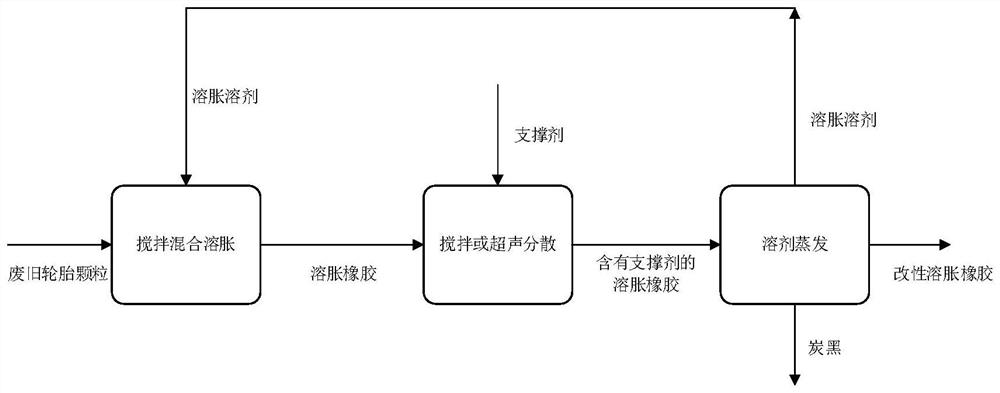

[0040] A processing method based on pyrolysis waste tires, comprising the steps of:

[0041]First, waste tires are crushed to obtain waste tire rubber particles with an average particle size of 13 mm; the waste tire rubber particles and toluene swelling solvent are stirred and mixed for 1 hour according to a mass ratio of 1:3, and the swelling process is completed for 3 hours; SiO2 of 10% weight of the dry weight of waste tire rubber particles is added in the rubber swelling solution, wherein SiO2 is used as the proppant powder, and the particle size range of SiO2 is 50 μm-150 μm; the rubber swelling solution added with the proppant powder is stirred, and the stirring speed is The temperature is 120r / min, and the stirring time is 100min; after that, it is heated to 120°C and evaporated at 120°C to evaporate the swelling solvent with toluene; finally, it is filtered to separate the swollen rubber particles, and the swelled rubber particles are used as Pyrolysis raw materials ar...

Embodiment 2

[0043] A processing method based on pyrolysis waste tires, comprising the steps of:

[0044] First, the waste tires are crushed to obtain waste tire rubber particles with an average particle size of 16mm; the waste tire rubber particles and carbon tetrachloride swelling solvent are stirred and mixed for 1 hour according to the mass ratio of 1:5, and then placed for 1 hour to complete Swelling treatment: adding potassium chloride with 20% weight of the dry weight of waste tire rubber particles to the rubber swelling solution, wherein potassium chloride is used as the proppant powder; stirring the rubber swelling solution added with the proppant powder, the stirring speed is 120r / min, the stirring time is 60min; then heated to 90°C, and the carbon tetrachloride swelling solvent was evaporated under the environment of 90°C, the obtained swollen rubber particles and carbon black, the swelled rubber particles were used as pyrolysis raw materials for pyrolysis operation , to comple...

Embodiment 3

[0046] A processing method based on pyrolysis waste tires, comprising the steps of:

[0047] First, crush the waste tires to obtain waste tire rubber particles with an average particle size of 16 mm; stir and mix the waste tire rubber particles and cyclohexane swelling solvent at a mass ratio of 1:4 for 1 hour, and leave for 2 hours to complete swelling Treatment; iron oxide with 10% weight of the dry weight of waste tire rubber particles is added to the rubber swelling solution, wherein iron oxide is used as proppant powder, and the particle size range of iron oxide is 500nm-20μm; for the rubber swelling solution added with proppant powder Stirring is carried out at a stirring speed of 120r / min, and at the same time ultrasonically assisted stirring is carried out at a power of 20kHz and 400W for a stirring time of 120min; then heated to 90°C, and the cyclohexane swelling solvent is evaporated under an environment of 90°C to obtain The swollen rubber particles and carbon black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com