Preparation method of porous carbon material, supercapacitor electrode and supercapacitor

A technology of porous carbon materials and supercapacitors, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc., can solve the problems of supercapacitors that cannot show performance, small effective specific surface area, poor conductivity, etc. , to achieve good wetting effect, good wetting effect and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

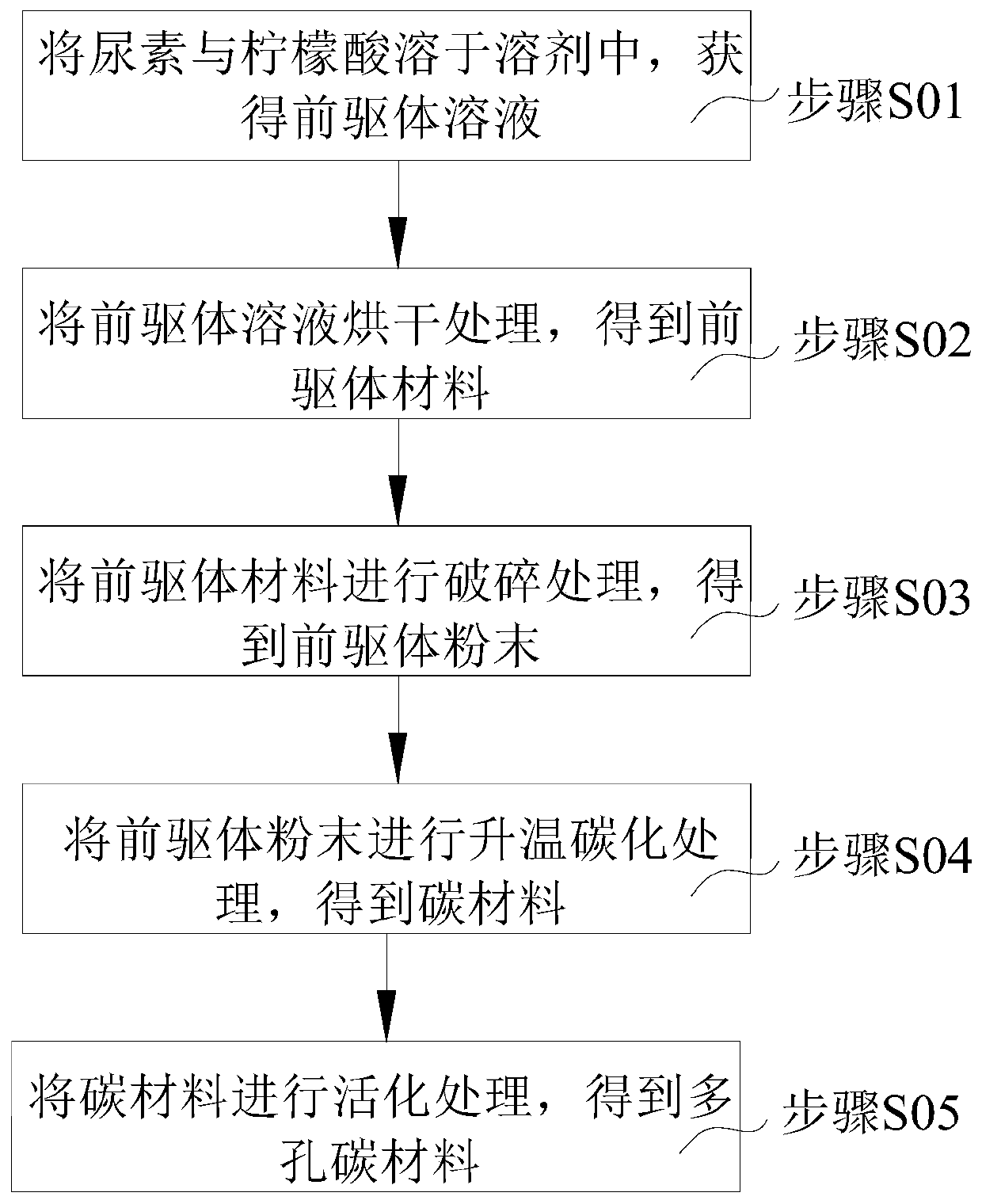

[0029] see figure 1 , the preparation method of the porous carbon material, comprising the following steps:

[0030] Step S01. Dissolving urea and citric acid in a solvent to obtain a precursor solution:

[0031] Step S02. Drying the precursor solution to obtain a precursor material;

[0032] Step S03. Crushing the precursor material to obtain precursor powder;

[0033] Step S04. heating the precursor powder to (700-1000) °C at a heating rate of (2-10) °C / min, carbonizing the precursor powder, and obtaining a carbon material with regular morphology;

[0034] Step S05. Mix the carbon material with an activator under a protective atmosphere, first raise the temperature to (360-400)°C at a heating rate of (2-10)°C / min, and keep warm for (20-30)min; then continue to (2-10) °C / min heating rate to (600-800) °C, and keep warm for (60-120) min to activate the carbon material to obtain a porous carbon material.

[0035] The above-mentioned preparation method will be explained in mo...

Embodiment 1

[0053] A preparation method of a porous carbon material and a supercapacitor. Wherein the preparation method of the porous carbon material comprises the following steps:

[0054] S11. Dissolve 4.2g of citric acid and 1.2g of urea in 10mL of deionized water and sonicate for 3min to obtain a colorless uniform solution;

[0055] S12. Put the solution prepared in step S11 in an oven, set the temperature of the oven at 120° C., react for 24 hours, and cool it down to room temperature naturally to obtain a precursor material;

[0056] S13. Grinding the precursor material into powder, sealed and stored for later use;

[0057] S14. Place the powder prepared above in a corundum crucible, put the crucible into a tube furnace, and feed argon gas to keep the flow rate of argon gas at 50mL / min; the tube furnace starts heating from room temperature, and the heating rate is 5°C / min, heated to 800°C and kept for 60min, then cooled to room temperature to obtain a carbon material with a regul...

Embodiment 2

[0074] A method for preparing a porous carbon material, comprising the steps of:

[0075] S21. Dissolve 2 g of citric acid and 12 g of urea in 50 mL of deionized water and sonicate for 3 min to obtain a colorless uniform solution;

[0076] S22. Put the solution prepared in step S21 in an oven, set the temperature of the oven to 200° C., and cool it down to room temperature naturally after reacting for 12 hours to obtain a precursor material;

[0077] S23. Grinding the precursor material into powder, sealed and stored for later use;

[0078] S24. Place the powder prepared above in a corundum crucible, put the crucible into a tube furnace, and feed argon gas to keep the flow rate of argon gas at 50mL / min; the tube furnace starts heating from room temperature, and the heating rate is 2°C / min, heating to 900°C for 50min, then cooling to room temperature to obtain carbon materials with regular morphology;

[0079] S25. Mix and grind 300 mg of the carbon material obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com