Beneficiation method for bastnaesite

A beneficiation method and bastnaesite technology, applied in flotation, solid separation and other directions, can solve the problems of little effect of sodium iron amphibole, and achieve the effects of good rare earth concentrate quality, stable index and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

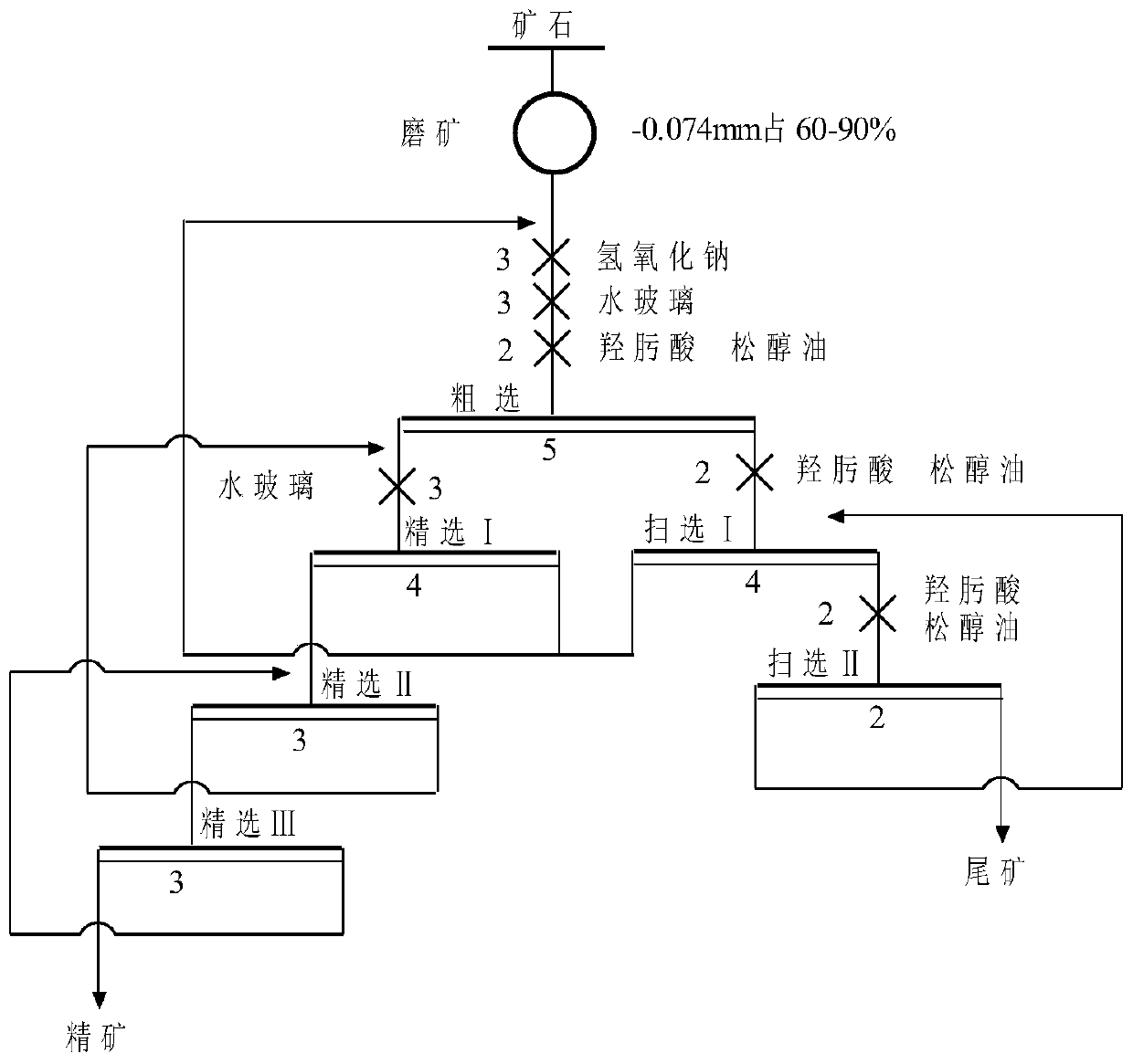

Image

Examples

Embodiment 1

[0034] A rare earth mine in Sichuan, the ore contains 4.16% REO, the main rare earth minerals are bastnaesite, pericite, allanite, iron minerals are hematite, limonite, and gangue minerals are mainly quartz and fluorite , barite, calcite, feldspar, sodium iron amphibole, muscovite, etc.

[0035] The beneficiation steps are as follows:

[0036] Pretreatment: mix the ore with water, the ore mass percentage concentration is 20%, and grind the ore to -0.074mm in a ball mill to account for 90%.

[0037] Adding agents: sodium hydroxide: add 100 grams per ton of ore; water glass: add 4000 grams per ton of ore; hydroxamic acid: add 4000 grams per ton of ore; pinitol oil: add 30 grams per ton of ore.

[0038] Stirring: Add the above-mentioned agents into the slurry in order, and stir while adding. After the last agent is added, continue to stir for 5 minutes.

[0039] Flotation: 3-10 minutes of flotation to obtain the rough concentrate of rare earth ore, and the rough concentrate is ...

Embodiment 2

[0042] A rare earth mine in Shandong, the ore contains 3.22% REO, the main rare earth minerals are bastnaesite, bastnaesite, ceriapatite, monazite and so on. Gangue minerals include calcite, barite, sodium iron amphibole, quartz, fluorite, mica and so on.

[0043] The beneficiation steps are as follows:

[0044] Pretreatment: mix the ore and water, the ore mass percentage concentration is 70%, and grind the ore to -0.074mm in a ball mill to account for 60%.

[0045]Adding agents: sodium hydroxide: add 900 grams per ton of ore; water glass: add 2000 grams per ton of ore; hydroxamic acid: add 1500 grams per ton of ore; pinitol oil: add 200 grams per ton of ore.

[0046] Stirring: Add the above-mentioned agents into the slurry in order, and stir while adding. After the last agent is added, continue to stir for 3 minutes.

[0047] Flotation: 3-10 minutes of flotation to obtain the rough concentrate of rare earth ore, and the rough concentrate is selected twice to obtain the rare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com