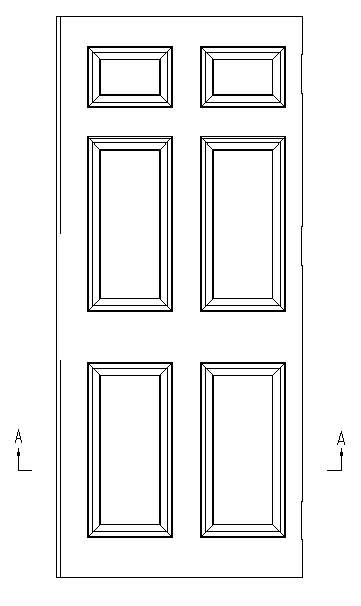

Steel-wood composite door

A composite door and steel-wood technology, which is applied in the field of steel-wood composite doors, can solve the problems of low-grade pure steel doors, high cost of wooden milling doors, and lack of aesthetic appearance, etc., and achieve low cost and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

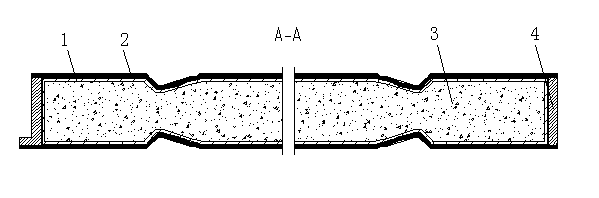

[0011] Such as Figure 1-2 As mentioned above, the present invention includes a steel skeleton 1, a wooden outer panel 2, and an inner filler 3. The steel skeleton 1 is formed of two U-shaped steel materials rolled and welded by two steel plates to form a hollow skeleton. The steel skeleton 1 is filled with the inner filler 3, the inner filler 3 is a whole piece of perlite fireproof board, and the whole piece of perlite fireproof board is used to replace the fireproof board formed by splicing small pieces, which prevents the fireproof board formed by splicing small pieces. The upper part of the steel-wood composite door loses its fireproof and heat insulation performance due to the sinking of the board for a long time. The inner and outer surfaces of the steel skeleton 1 are provided with the wooden outer board 2. The side of the steel skeleton 1 is bounded by solid wood 4, so that the overall appearance of the steel-wood composite door is neat and tidy.

[0012] The steel-wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com