Vanadium extraction method of ultralow-silicon vanadium-titanium molten iron converter

A kind of molten iron, vanadium and titanium technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for extracting vanadium in an ultra-low silicon vanadium-titanium molten iron, wherein the mass content of Si in the ultra-low silicon vanadium-titanium molten iron is <0.1%;

[0052] The described converter vanadium extraction method comprises the steps:

[0053] Step (1), adding ultra-low silicon vanadium titanium molten iron and pig iron into the converter, followed by blowing;

[0054] When the mass content of Si in ultra-low silicon vanadium-titanium molten iron is (0.1%-0.02%X), X is a positive number, and the mass ratio of pig iron to ultra-low silicon vanadium-titanium molten iron is (0.5+0.5X): 51;

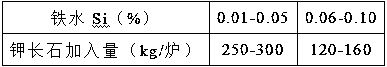

[0055] Step (2), after the blowing and ignition is completed, potassium feldspar is added for slag adjustment;

[0056] When the mass content of Si in ultra-low silicon vanadium-titanium hot metal is [0.01%, 0.05%], the mass ratio of potassium feldspar to ultra-low silicon vanadium-titanium hot metal is 0.25:51; when the mass content of Si in ultra-low si...

Embodiment 2

[0059] A method for extracting vanadium in an ultra-low silicon vanadium-titanium molten iron, wherein the mass content of Si in the ultra-low silicon vanadium-titanium molten iron is <0.1%;

[0060] The described converter vanadium extraction method comprises the steps:

[0061] Step (1), adding ultra-low silicon vanadium titanium molten iron and pig iron into the converter, followed by blowing;

[0062] When the mass content of Si in ultra-low silicon vanadium-titanium molten iron is (0.1%-0.02%X), X is a positive number, and the mass ratio of pig iron to ultra-low silicon vanadium-titanium molten iron is (0.5+0.5X): 53;

[0063] Step (2), after the blowing and ignition is completed, potassium feldspar is added for slag adjustment;

[0064] When the mass content of Si in ultra-low silicon vanadium-titanium hot metal is [0.01%, 0.05%], the mass ratio of potassium feldspar to ultra-low silicon vanadium-titanium hot metal is 0.30:53; when the mass content of ultra-low silicon ...

Embodiment 3

[0071] A method for extracting vanadium in an ultra-low silicon vanadium-titanium molten iron, wherein the mass content of Si in the ultra-low silicon vanadium-titanium molten iron is <0.1%;

[0072] The described converter vanadium extraction method comprises the steps:

[0073] Step (1), adding ultra-low silicon vanadium titanium molten iron and pig iron into the converter, followed by blowing;

[0074] When the mass content of Si in ultra-low silicon vanadium-titanium molten iron is (0.1%-0.02%X), X is a positive number, and the mass ratio of pig iron to ultra-low silicon vanadium-titanium molten iron is (0.5+0.5X): 52;

[0075] Step (2), after the blowing and ignition is completed, potassium feldspar is added for slag adjustment;

[0076] When the mass content of Si in ultra-low silicon vanadium-titanium hot metal is [0.01%, 0.05%], the mass ratio of potassium feldspar to ultra-low silicon vanadium-titanium hot metal is 0.28:52; when the mass content of Si in ultra-low si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com