Preparation method of amorphous MoS2-modified CoS/Co0.85Se heterogeneous nanotube array electrocatalyst

A technology of nanotube arrays and electrocatalysts, applied in physical/chemical process catalysts, chemical instruments and methods, nanotechnology, etc., can solve the problems of long preparation time, cumbersome operation, high energy consumption, etc., and achieve easy control and good repeatability , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

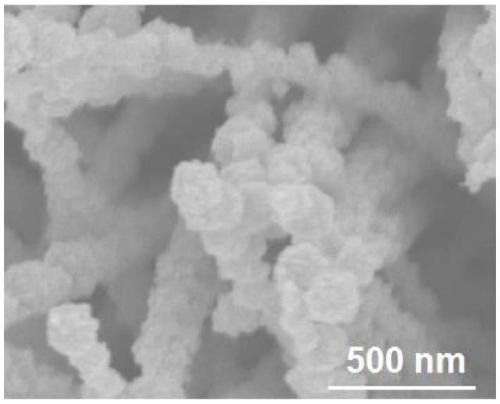

[0024] First cut out a nickel foam of 2cm×4cm, put it in 3M hydrochloric acid (HCl) and ultrasonically clean it for 15 minutes, wash it with water and ethanol in turn, and dry it under vacuum at 60°C for 3 hours for later use. Then using water as solvent, add 0.69g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.18g ammonium fluoride (NH 4 F) and 0.72g urea (CO(NH) 2 ), formed a 35ml homogeneous solution by ultrasonic dispersion. The above solution was transferred to a reactor, and a piece of pretreated nickel foam (2cm×4cm) was added into the reactor, and reacted at 120°C for 9 hours. After the reaction, cool to room temperature, wash with distilled water and absolute ethanol, and dry in vacuum at 60°C to obtain Co(CO 3 ) 0.5 (OH) nanorod arrays.

[0025] Take 1g of selenium powder (Se) and dissolve it in 35ml of ethanol and N,N-dimethylformamide (DMF) mixed solution (v:v=2:5), after ultrasonication for 10 minutes, transfer it to the reaction kettle, and then Add the above-pr...

Embodiment 2

[0028] First cut out a nickel foam of 2cm×4cm, put it in 3M hydrochloric acid (HCl) and ultrasonically clean it for 15 minutes, wash it with water and ethanol in turn, and dry it under vacuum at 60°C for 3 hours for later use. Then using water as solvent, add 0.69g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.18g ammonium fluoride (NH 4 F) and 0.72g urea (CO(NH) 2 ), through ultrasonic dispersion, prepared into a 35ml solution. The above solution was transferred to a reactor, and a piece of pretreated nickel foam (2cm×4cm) was added into the reactor, and reacted at 120°C for 9 hours. After the reaction, cool to room temperature, wash with distilled water and absolute ethanol, and dry in vacuum at 60°C to obtain Co(CO 3 ) 0.5 (OH) nanorod arrays.

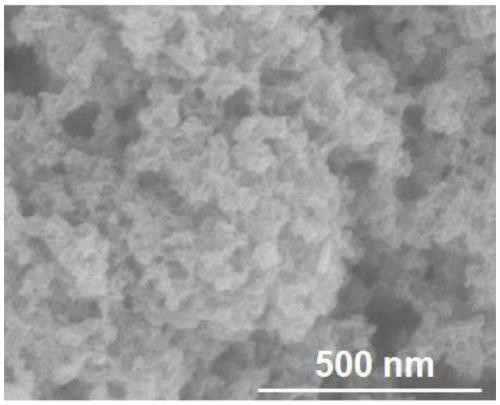

[0029] Take 0.91g ((NH 4 ) 2 MoS 4 ) was dissolved in 35ml of ethanol and N,N-dimethylformamide (DMF) mixed solution (v:v=2:5), after ultrasonication for 10 minutes, it was transferred to the reaction kettle, and then the above-...

Embodiment 3

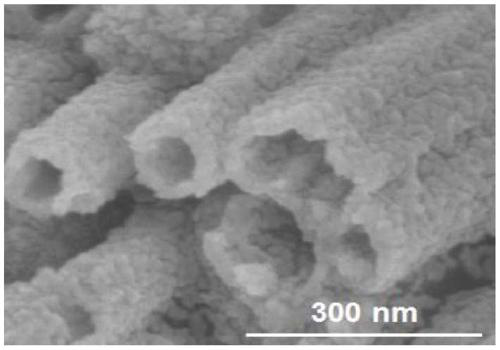

[0032] First cut out a nickel foam of 2cm×4cm, put it in 3M hydrochloric acid (HCl) and ultrasonically clean it for 15 minutes, wash it with water and ethanol in turn, and dry it under vacuum at 60°C for 3 hours for later use. Then using water as solvent, add 0.69g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.18g ammonium fluoride (NH 4 F) and 0.72g urea (CO(NH) 2 ), was dispersed by ultrasound to prepare a 35ml homogeneous solution. The above solution was transferred to a reactor, and a piece of pretreated nickel foam (2cm×4cm) was added into the reactor, and reacted at 120°C for 9 hours. After the reaction, cool to room temperature, wash with distilled water and absolute ethanol, and dry in vacuum at 60°C to obtain Co(CO 3 ) 0.5 (OH) nanorod arrays.

[0033] Get 1g selenium powder (Se) and 0.91g ((NH 4 ) 2 MoS 4 ) was dissolved in 35ml of ethanol and N,N-dimethylformamide (DMF) mixed solution (v:v=2:5), after ultrasonication for 10 minutes, it was transferred to the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com