Preparation method and application of modified carbon nanotube adsorbent

A technology of magnetic carbon nanotubes and multi-walled carbon nanotubes, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as poor adhesion uniformity and low adsorption capacity of metal ions, and achieve adhesion Strong junction, convenient magnetization and cross-linking treatment, corrosion resistance to chemical media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

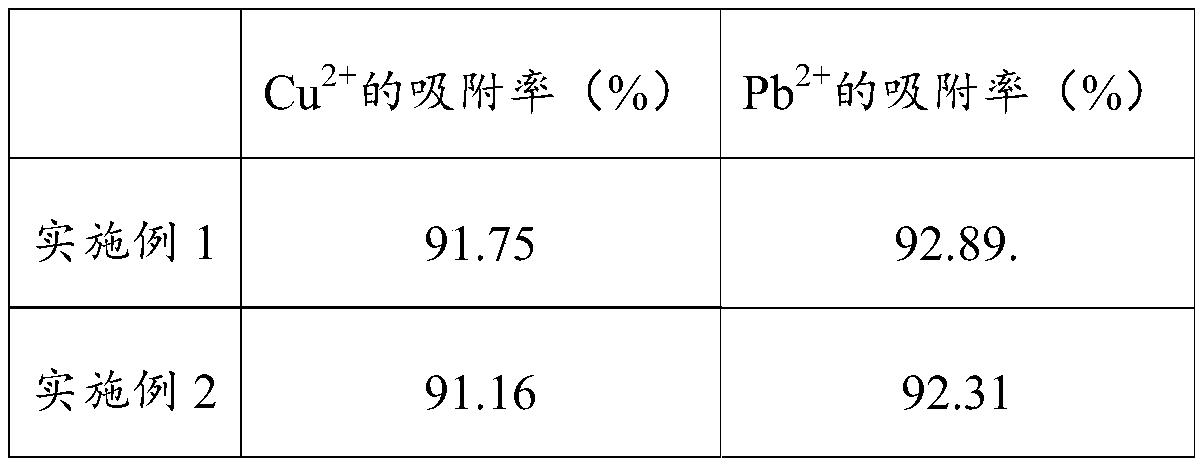

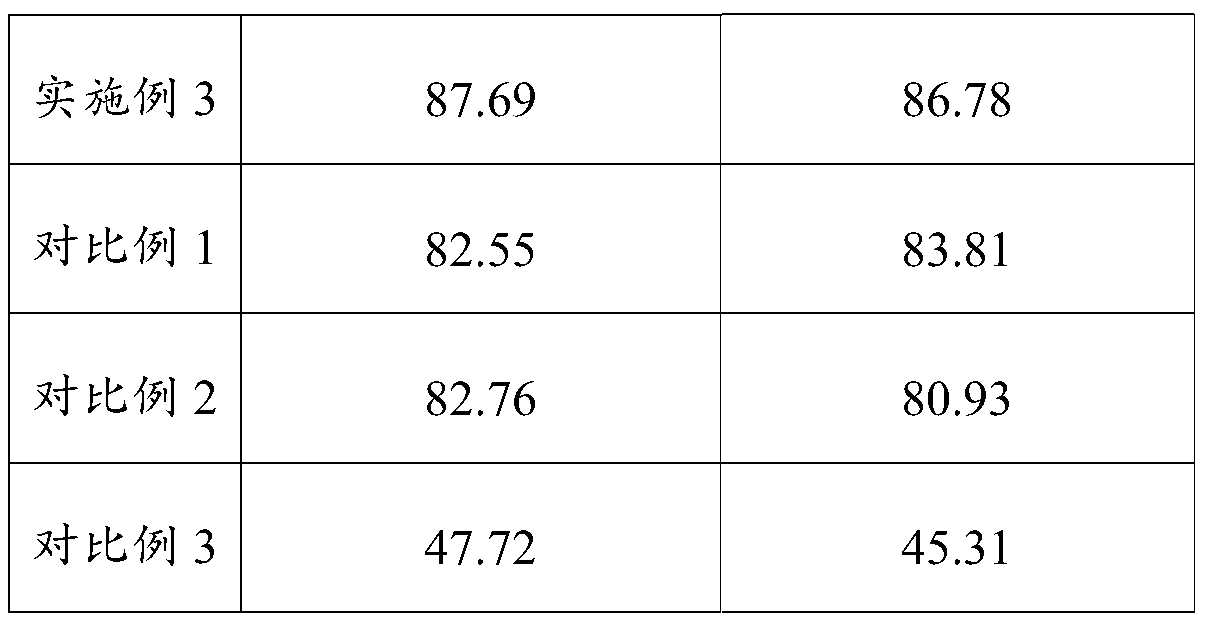

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a modified carbon nanotube adsorbent, comprising the following steps:

[0031] (1) Purification steps: first use an analytical balance to accurately weigh 6g of multi-walled carbon nanotubes and place them in a beaker, add a mixed acid solution of 180ml of concentrated sulfuric acid and 60ml of concentrated nitric acid, ultrasonically disperse for 35min at room temperature, and then disperse at 80°C at 800r / min speed, stirred with a magnetic stirring device for 3 hours, after standing for 12 hours once, diluted 8 times with pure water, and stood for 10 hours for the second time, then washed the precipitate alternately with ultrapure water and absolute ethanol and suction filtered , in a constant-temperature vacuum drying oven at 80°C for 12 hours at a constant temperature and then grind evenly to obtain purified multi-walled carbon nanotubes;

[0032] (2) Magnetization step: take 1 g of purified multi-walled carbon nanotu...

Embodiment 2

[0036] This embodiment provides a method for preparing a modified carbon nanotube adsorbent, comprising the following steps:

[0037](1) Purification steps: first use an analytical balance to accurately weigh 6g of multi-walled carbon nanotubes and place them in a beaker, add a mixed acid solution of 200ml of concentrated sulfuric acid and 70ml of concentrated nitric acid, ultrasonically disperse for 50min at room temperature, and then disperse at 90°C at 1000r / min speed, stir with a magnetic stirring device for 4 hours, after standing for 15 hours once, dilute 10 times with pure water, and let stand for 12 hours for the second time, then alternately wash the precipitate with ultrapure water and absolute ethanol and suction filter , and then in a constant temperature vacuum drying oven, carry out constant temperature drying at 90° C. for 15 hours, and then grind evenly to obtain purified multi-walled carbon nanotubes;

[0038] (2) Magnetization step: take 1 g of purified mult...

Embodiment 3

[0042] This embodiment provides a method for preparing a modified carbon nanotube adsorbent, comprising the following steps:

[0043] (1) Purification steps: first use an analytical balance to accurately weigh 6g of multi-walled carbon nanotubes and place them in a beaker, add a mixed acid solution of 200ml of concentrated sulfuric acid and 70ml of concentrated nitric acid, ultrasonically disperse for 50min at room temperature, and then disperse at 90°C at 1000r / min speed, stir with a magnetic stirring device for 4 hours, after standing for 15 hours once, dilute 10 times with pure water, and let stand for 12 hours for the second time, then alternately wash the precipitate with ultrapure water and absolute ethanol and suction filter , and then in a constant temperature vacuum drying oven, carry out constant temperature drying at 90° C. for 15 hours, and then grind evenly to obtain purified multi-walled carbon nanotubes;

[0044] (2) Magnetization step: take 1 g of purified mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com