Solid pollutant remover spraying device with flange-type inlet

A spraying device and removal agent technology, applied in liquid spraying devices, spraying devices, gas treatment, etc., can solve the problem of incomplete coverage of the flue flow surface, lower pollutant absorption rate\adsorption rate, and unsatisfactory particle diffusion effect and other issues, so as to improve the level of environmental governance, avoid the impact of pressure, and ensure the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

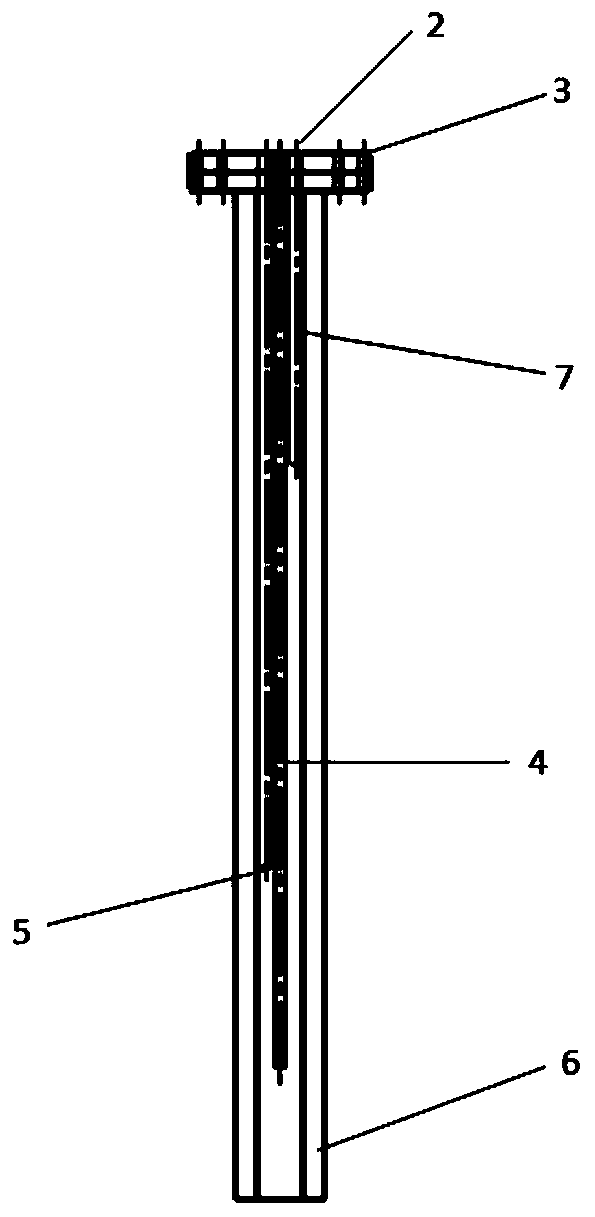

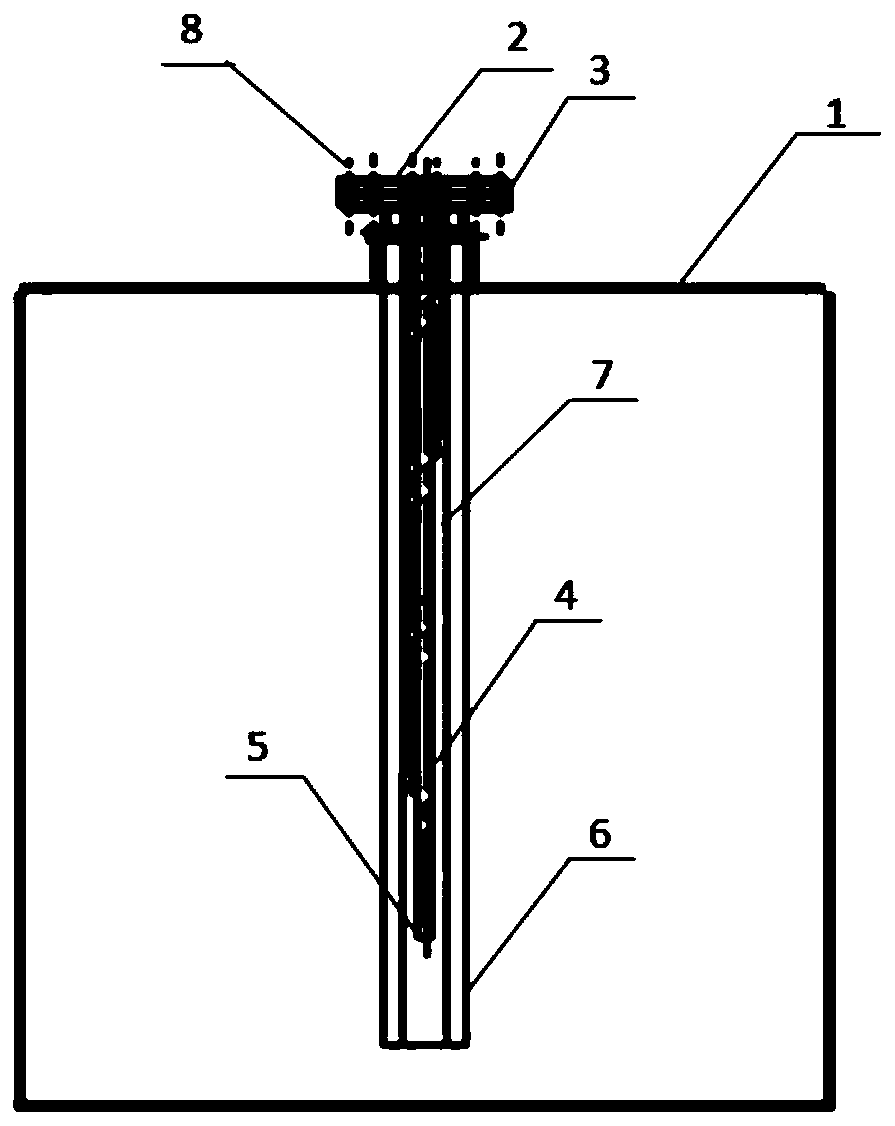

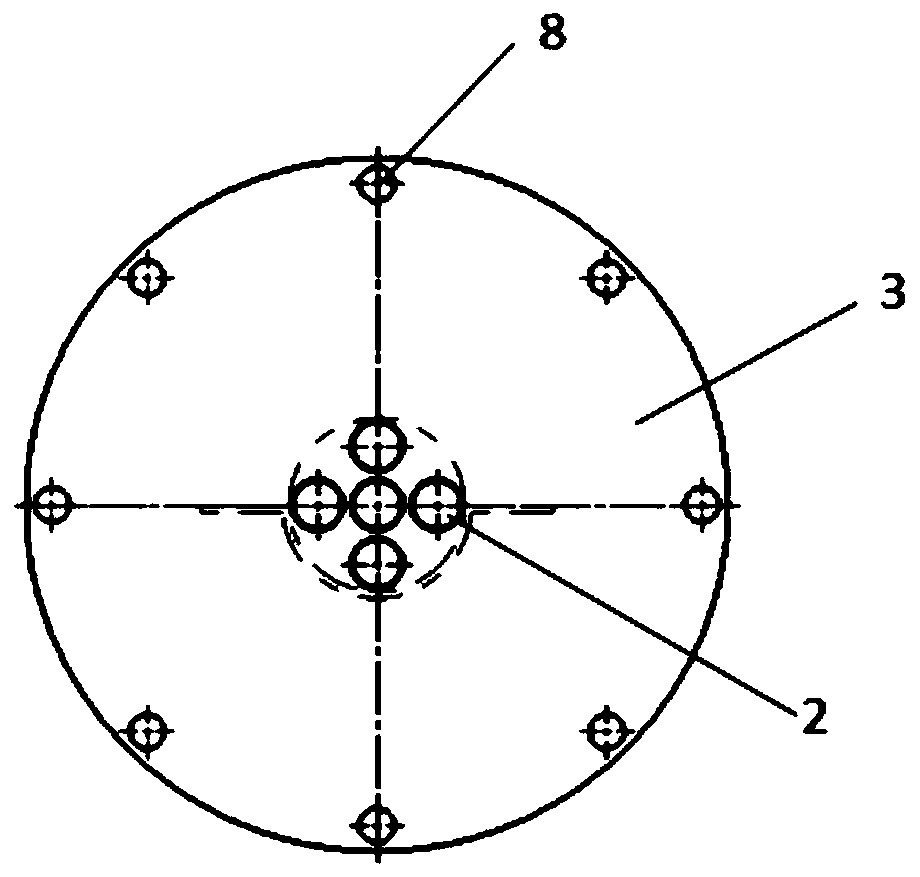

[0029] Such as Figure 1 ~ Figure 2 and Figure 5 As shown, the remover injection device of the present invention includes a flue 1, the flue gas circulates in the flue 1, the flue gas flows from front to back along the flue 1, and the remover spray gun 4 is set in the flue 1, The stripper spray gun 4 comprises the stripper inlet 2 of the upper end, the stripper spray gun flange plate 3 fixed by the bolt 8, the stripper outlet 5 arranged at the lower end of several quantity stripper spray guns 4 and the stripper outlet 5 which is welded on the stripper by the bracket. Remover deflector 6 except the nozzle 7 of agent spray gun 4, the length of remover deflector 6 perpendicular to flue 1 is (n+1) / of the length of the longest one in nozzle 7 n, n is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com