Improved environment-friendly water-based photoresist stripping liquid

A technology of photoresist and stripping liquid, which is applied in the directions of optics, photomechanical equipment, photosensitive material processing, etc., can solve the problems of poor conductivity, large impedance, and distortion of pattern line width, so as to weaken the protection ability and realize the selection Etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1

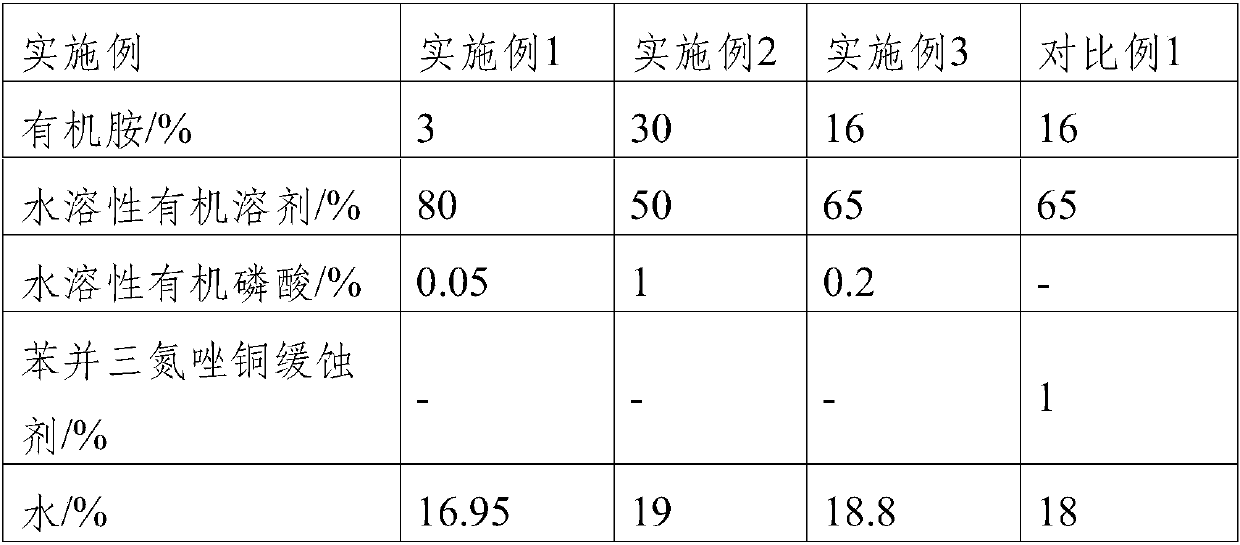

[0031] The improved environment-friendly water system photoresist stripping liquid composition (by weight percentage) among the embodiment (abbreviation S, the same below) 1-11 sees the following table:

[0032]

[0033] In Examples 1-3 and Comparative Example 1, the organic amine is triethanolamine, the water-soluble organic solvent is diethylene glycol dimethyl ether, and the water-soluble organic phosphoric acid is a compound with a primary amino group and a phosphoric acid group in the molecular structure. (1-aminobutyl) phosphoric acid.

Embodiment 4

[0034] Embodiment 4 is based on comparative example 3, difference is that organic amine is diethanolamine, water-soluble organic solvent is diethylene glycol monomethyl ether.

[0035] Embodiment 5-9 is based on embodiment 4, difference is:

Embodiment 5

[0036] Embodiment 5 The water-soluble organic phosphoric acid is the aminobis(methylene phosphoric acid) having a secondary amino group and two phosphoric acid groups in the molecular structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com