Ultra-thin MXene nanometer material as well as preparation method and application thereof

A nano-material and ultra-thin technology, applied in the field of electrochemistry, can solve problems such as complex operation procedures, limited applications, and poor selectivity, and achieve good application prospects, unique metal conductivity, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 ultra-thin MXene nanomaterial

[0034] (1) The preparation method is as follows

[0035] 1. Preparation of multilayer MXene nanomaterials

[0036] Add 120 mL of 40% hydrofluoric acid to a plastic beaker, then place it in an oil bath, and slowly add 1 g of Ti 3 AlC 2 Stir continuously, react at 25°C for 72h, centrifuge the product at 3500rpm for 5min, wash with water, repeat several times until pH = 6, and dry in vacuum at 60°C for 12h to obtain multilayer MXene nanomaterials.

[0037] 2. Preparation of ultrathin MXene nanomaterials

[0038] Add 0.5g of multilayer MXene to 100mL dimethyl sulfoxide (DMSO), heat and stir in an oil bath at 25°C for 100h, then let it stand for 3h, then ultrasonicate for 5h, centrifuge the product at 3500rpm for 10min, and pump the supernatant Filter and dry in a vacuum oven at 60°C for 12 hours to obtain ultrathin MXene nanomaterials.

[0039] (2) Test results

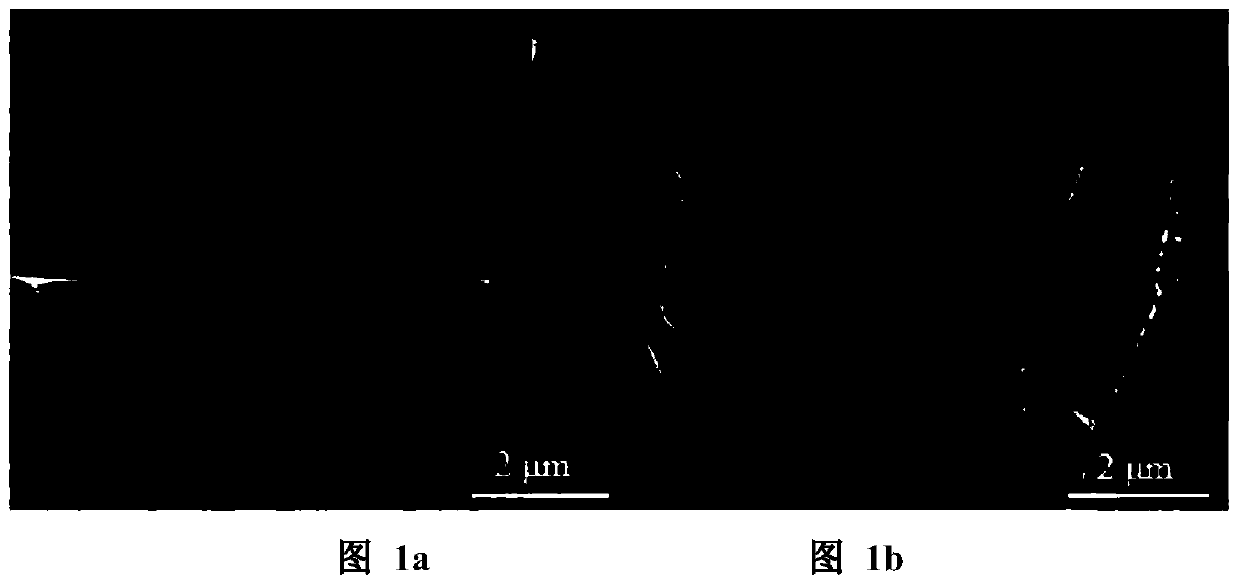

[0040] Figure 1a is the SEM topography of ultra-thin MXene n...

Embodiment 2

[0042] Embodiment 2 Preparation of Modified Electrode

[0043] (1) Electrode pretreatment

[0044] Use 0.1, 0.3, 0.05μm A1 respectively 2 o 3 Polish the glassy carbon electrode. Then, ultrasonic cleaning was performed with acetone, ethanol, and ultrapure water for 1 min in sequence. The glassy carbon electrode is used as the working electrode, the Ag / AgCl electrode is used as the reference electrode, and the platinum wire is used as the counter electrode. -3 mol / L K 3 Fe(CN) 6 The electrochemical cyclic voltammetry (CV) test was carried out in the 1mol / L KCl solution, and the scanning range was -0.2-1.0V (vs.Ag / AgCl). After the test, the electrodes were cleaned with ultrapure water and dried with high-purity nitrogen gas for later use.

[0045] (2) Preparation of ultrathin MXene nanomaterial modified electrode

[0046] The ultra-thin MXene nanomaterial prepared in Example 1 was dissolved in water, and 5 μL of the ultra-thin MXene nanomaterial aqueous solution with a co...

Embodiment 3

[0057] Example 3 Ultrathin MXene Nanomaterial Modified Electrode Catalytic Detection Performance of Catechol

[0058] (1) Detection performance of ultra-thin MXene nanomaterial modified electrode for different concentrations of catechol

[0059] The ultra-thin MXene modified electrode prepared in Example 2 (two) is used as the working electrode, the Ag / AgCl electrode is the reference electrode, and the platinum electrode is the auxiliary electrode, and 1.0, 1.5, 2.0 , 2.5, 3.5, 4.5, 5.5, 6.5, 7.5, 8.5 μmol / L (a-j) of catechol, the test results are shown in Figure 5, Figure 5a is the differential pulse voltammogram at different catechol concentrations, Figure 5b It is a calibration diagram of the peak current changing with the concentration of catechol. When the concentration of catechol in the supporting electrolyte gradually increases, the oxidation peak current of the modified electrode will gradually increase, which proves that the modified electrode has a good catalytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com