Hypoeutectoid steel rail post-weld heat processing method

A post-weld heat treatment and hypoeutectoid technology, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems not involved in post-weld heat treatment methods of hypoeutectoid rails, and achieve the effect of ensuring service performance and railway operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The hypoeutectoid rail welded joint obtained by flash welding at a temperature of 1200 °C was air-cooled. When the joint was cooled from 1200 °C to 180 °C, the medium-frequency induction profiling electric heating coil was used to heat the entire section of the rail welded joint area. Stop heating when the tread temperature of the rail reaches 900°C, then immediately air-cool the obtained rail welded joint to 350°C, and finally air-cool the welded joint to room temperature (25°C), thereby obtaining the post-weld heat-treated sub- Eutectoid rail welded joints.

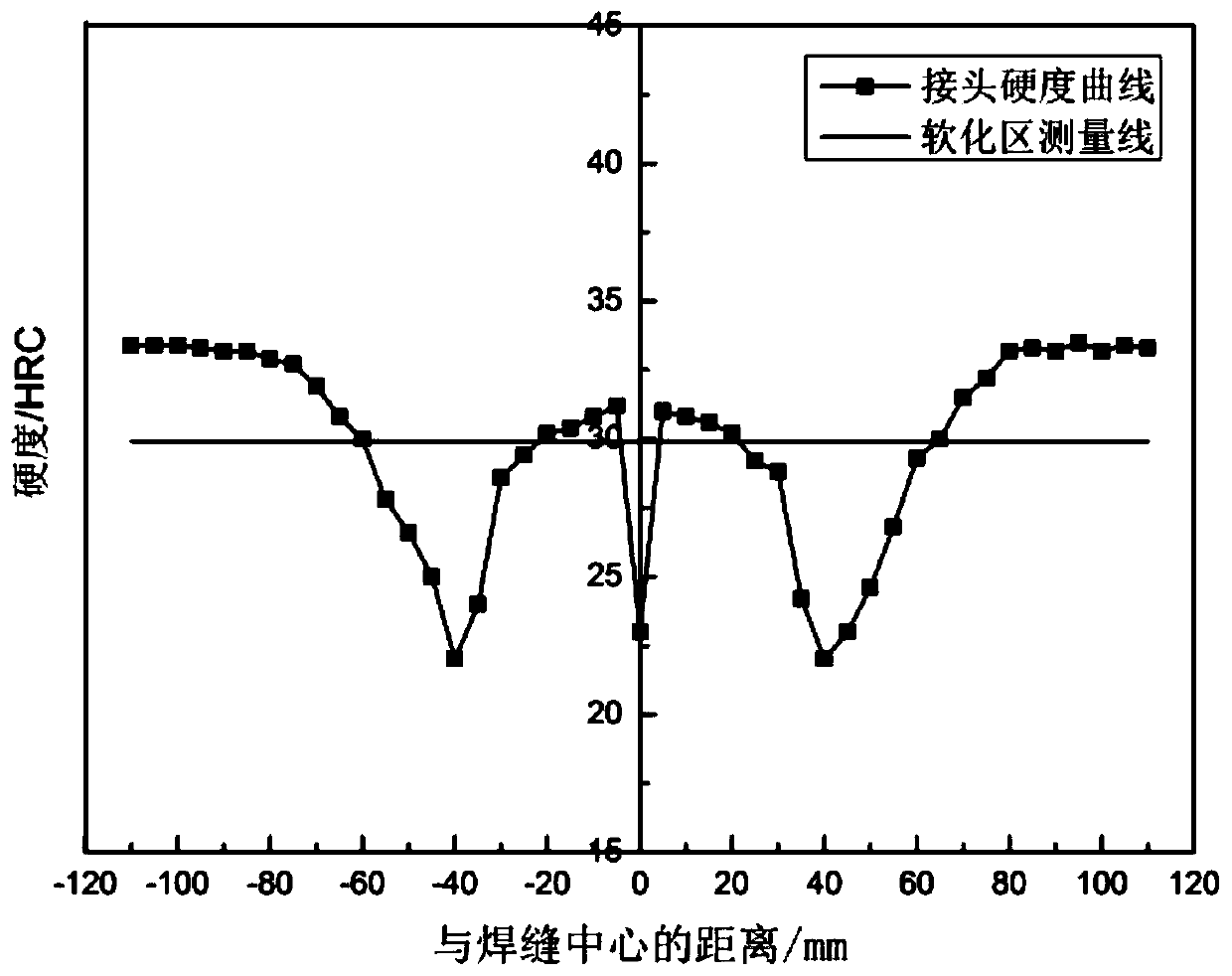

[0038] The hypoeutectoid rail welded joint obtained in this embodiment is machined into a longitudinal hardness sample, and the longitudinal Rockwell hardness test is carried out on the welded joint at a position 5 mm below the tread. The measuring points are arranged symmetrically to the left and right sides with the weld seam as the center. The measuring point spacing is 5mm. The Rockwell hardness test method ...

Embodiment 2

[0043] Air-cool the hypoeutectoid rail welded joint with a temperature of 1300°C obtained by gas pressure welding. When the welded joint is cooled from 1300°C to 200°C, use an oxygen-acetylene flame profiling heater to heat the entire section of the welded joint area of the rail . Stop heating when the tread temperature of the rail reaches 920°C, then air-cool the welded joint of the rail to 380°C, and finally air-cool the welded joint to room temperature (25°C), thereby obtaining the post-weld heat-treated hypoeutectoid rail of the present invention Welded joints.

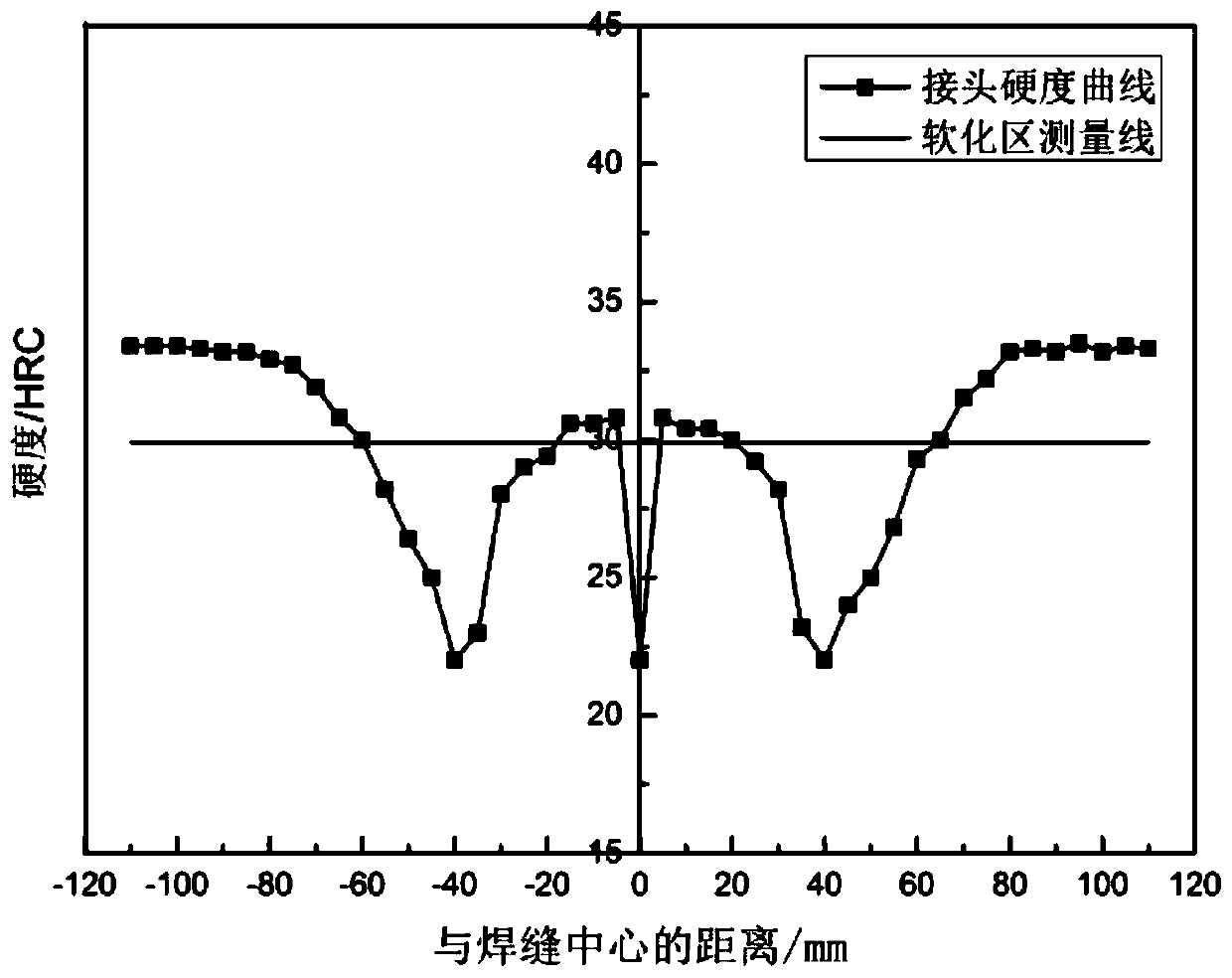

[0044] Take the longitudinal hardness sample of the hypoeutectoid rail welded joint obtained in this embodiment and carry out the longitudinal Rockwell hardness test at the position 5 mm below the rail head tread. 5mm. The Rockwell hardness test method is carried out according to the provisions of GB / T 230.1-2009, and the HRC scale is used. The longitudinal hardness data at the 5mm position below the rail hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com