Preparation and immune-enhancement use of lucid ganoderma liquid fermentation extracellular active polysaccharides

A liquid fermentation, active polysaccharide technology, applied in the direction of fermentation, organic active ingredients, medical preparations containing active ingredients, etc., can solve the problems of long production cycle and low production efficiency, and achieve the effect of good immune activity and enhanced immune activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of ganoderma lucidum liquid-fermented extracellular active polysaccharide, in which slant medium: 39g of potato dextrose agar dissolved in 1L of deionized water and sterilized.

[0029] The formula of seed medium: glucose 30g / L, yeast powder 3g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, pH natural.

[0030] The recipe of the fermentation medium:

[0031] Formula 1: Glucose 20-30g / L, yeast powder or yeast extract 2-4g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, pH natural.

[0032] Formula 2: Galactose 20-30g / L, yeast powder or yeast extract 2-4g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, pH natural.

[0033]Formula 3: fructose 20-30g / L, yeast powder or yeast cream 2-4g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, pH natural.

[0034] Formula 4: Mannose 20-30g / L, yeast powder or yeast extract 2-4g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, pH natural.

[0035] Formula 5: xylose 20-30g / L, yeast powder or yeast extract 2-4g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H...

Embodiment 1

[0038] Step 1: Ganoderma lucidum liquid fermentation culture: first transfer the Ganoderma lucidum strain to the flat PDA medium, the flat PDA medium is: glucose 30g / L, yeast powder 3g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, natural pH, cultured in a 25-30°C incubator for 5-7 days to activate, after the mycelium covered the plate, pick about 3-6mm 2 Bacteria blocks of large and small sizes are inserted into 250mL shake flasks with a liquid volume of 100mL to carry out liquid fermentation and culture for 7-10 days to obtain a first-class seed liquid;

[0039] Step 2: Insert 10% of the inoculum into the secondary medium, the secondary seed liquid medium is: glucose 30g / L, yeast powder 3g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, pH is natural, after cultivating for 7-10d, the secondary seed liquid is obtained, then according to the inoculum amount of 10%, it is inserted into the culture liquid of different medium formulations, cultivated on a shaker for 7-10d, and the rotati...

Embodiment 2

[0061] The seed liquid was inoculated into the fermentation medium formula 2 for cultivation, and the extracellular liquid was collected according to the method in Example 1 for alcohol precipitation treatment to obtain the large molecular weight polysaccharide component 20E.

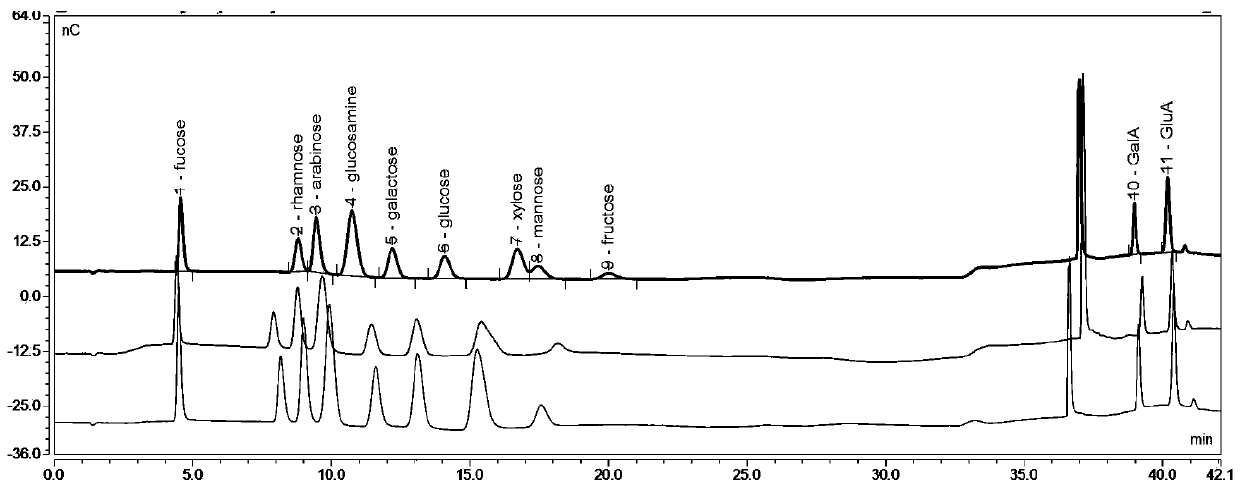

[0062] With galactose as the carbon source and yeast powder as the nitrogen source, the yield of the 20E component obtained is 1.52g / L. The polysaccharide content of this component is 70.53%, and its monosaccharide composition and molar percentage are glucose (56.16%), Xylose (2.78%), Mannose (7.54%), Galactose (33.53%);

[0063] With glucose as carbon source and yeast extract as nitrogen source, the yield of 20E component is 1.88g / L, the polysaccharide content of this component is 66.84%, and its monosaccharide composition and mole percentage are glucose (13.12%), xylose (2.93%), mannose (2.98%), galactose (80.97%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com