Preparation method of ultra-high molecular weight polyethylene/montmorillonite nano composite material

A nano-composite material and ultra-high molecular weight technology, which is applied in the field of preparation of ultra-high molecular weight polyethylene/montmorillonite nano-composite materials, can solve the problems of poor hydrogen response, difficult industrial production, and low bulk density of polymerization products, and achieve polymerization High activity, good mechanical strength and heat resistance, good effect of hydrogen adjustment sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

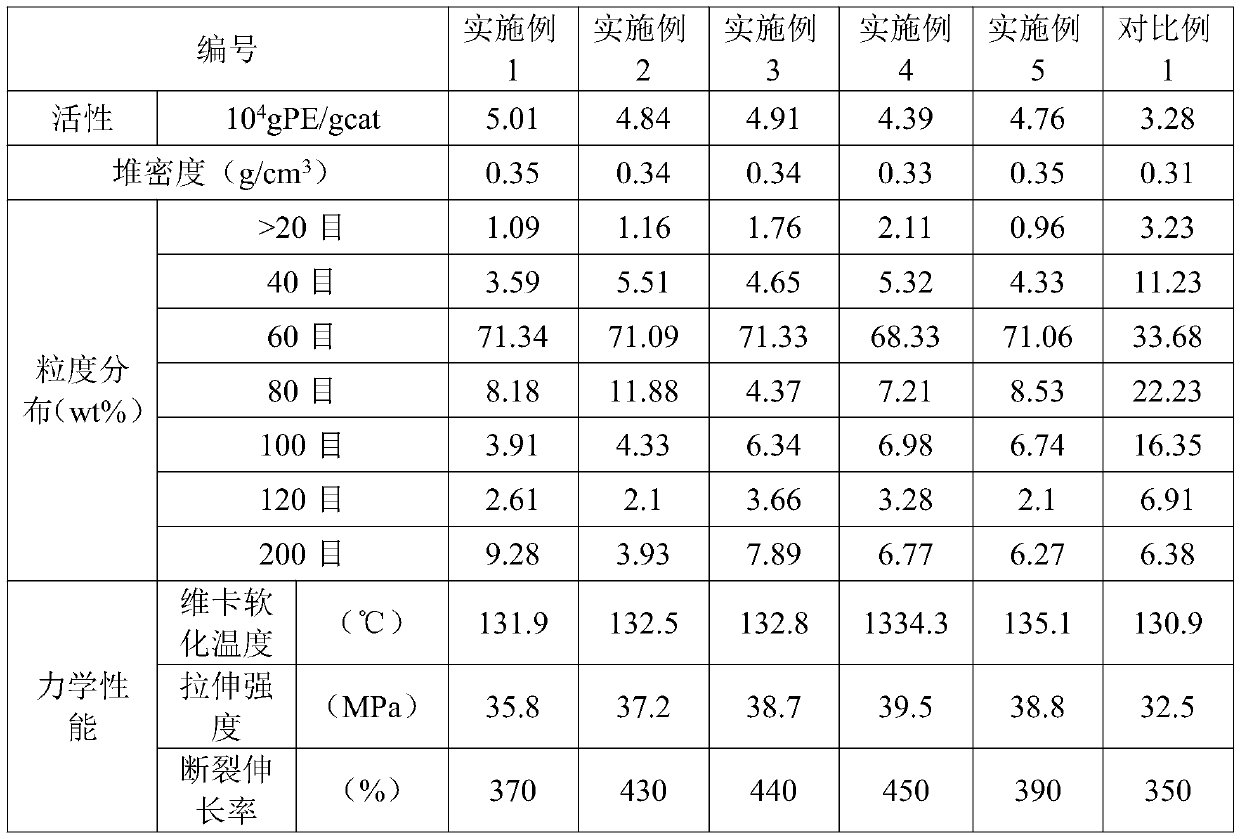

Examples

Embodiment 1

[0034] (1) Silanization treatment of montmorillonite

[0035] ① Scatter montmorillonite. Add 100g of sodium montmorillonite and 1g of sodium hexametaphosphate to 1500mL of distilled water, stir and disperse for 2h, and then continue to disperse in a high-speed disperser for 0.5h.

[0036] ② γ-aminopropyltriethoxysilane (APMS) silylated montmorillonite. Take 1g APMS in 10mL1:100 H 2 Stir in the O / ethanol system at room temperature for 2 hours, drop into the dispersed montmorillonite suspension, reflux and stir for 5 hours, filter, dry the filter cake at 120°C for 15 hours, and continue to extract the dried montmorillonite with absolute ethanol Soxhlet 24h to extract the physically adsorbed coupling agent on the montmorillonite.

[0037] (2) Preparation of montmorillonite / magnesium chloride supported titanium tetrachloride catalyst

[0038] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and a...

Embodiment 2

[0044] (1) Silanization treatment of montmorillonite

[0045] ① Scatter montmorillonite. Add 100g of sodium montmorillonite and 1g of sodium hexametaphosphate to 1500mL of distilled water, stir and disperse for 2h, and then continue to disperse in a high-speed disperser for 0.5h.

[0046] ② γ-aminopropyltriethoxysilane (APMS) silylated montmorillonite. Take 2.5g APMS in 10mL 1:100 H 2 Stir in the O / ethanol system for 2 hours at room temperature, drop into the dispersed montmorillonite suspension, reflux and stir for 5 hours, filter, and dry the filter cake at 120°C for 15 hours. Extract for 24 hours to extract the coupling agent physically adsorbed on the montmorillonite.

[0047] (2) Preparation of montmorillonite / magnesium chloride supported titanium tetrachloride catalyst

[0048] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solu...

Embodiment 3

[0054] (1) Silanization treatment of montmorillonite

[0055] ① Scatter montmorillonite. Add 100g of sodium montmorillonite and 1g of sodium hexametaphosphate to 1500mL of distilled water, stir and disperse for 2h, and then continue to disperse in a high-speed disperser for 0.5h.

[0056] ② γ-aminopropyltriethoxysilane (APMS) silylated montmorillonite. Take 5.0g APMS in 10mL 1:100 H 2 Stir in the O / ethanol system for 2 hours at room temperature, drop into the dispersed montmorillonite suspension, reflux and stir for 5 hours, filter, and dry the filter cake at 120°C for 15 hours. Extract for 24 hours to extract the coupling agent physically adsorbed on the montmorillonite.

[0057] (2) Preparation of montmorillonite / magnesium chloride supported titanium tetrachloride catalyst

[0058] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com