Cyanide particle removal electrode and preparation method and method and apparatus for treating high-concentration cyanide-containing wastewater

A particle electrode and cyanide wastewater technology, which is applied in the direction of neutralization water/sewage treatment, water/sewage treatment, metallurgical wastewater treatment, etc., can solve the problems of inability to oxidize wastewater, cyanide oxidation, and high electricity costs. Achieve the effect of light weight, less floor space and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

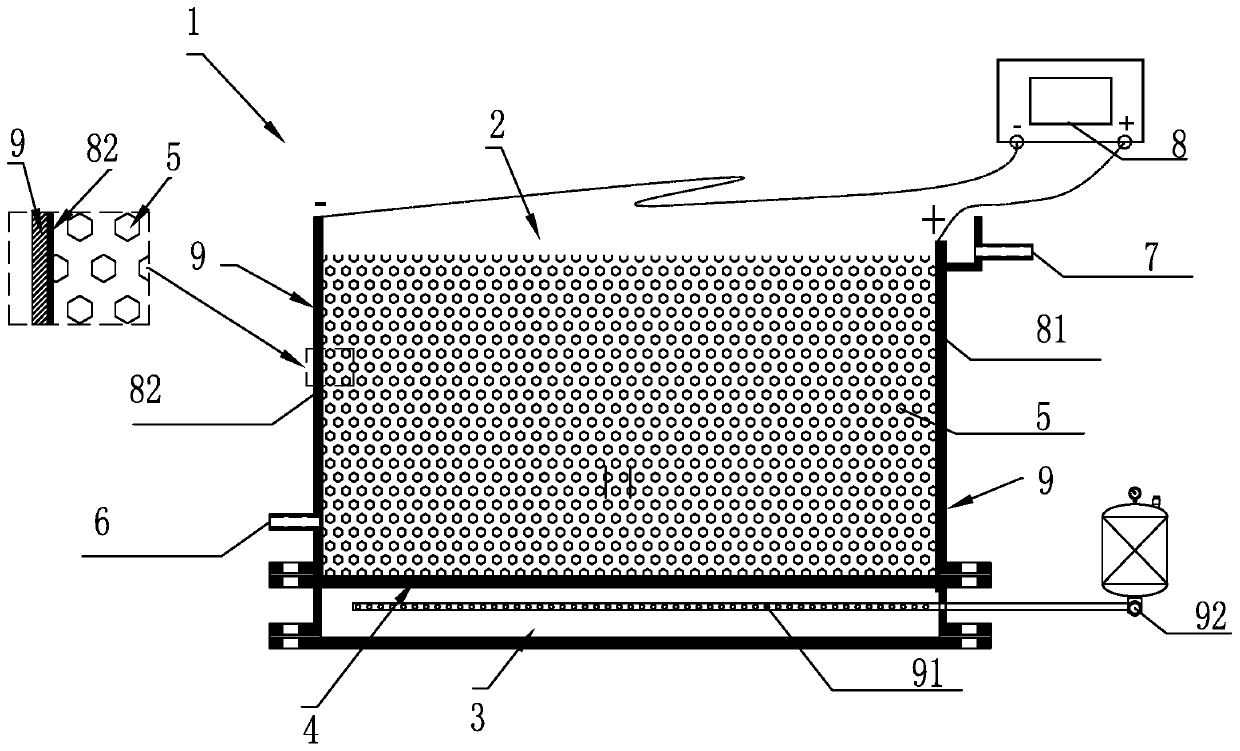

[0052] 1. Cyanide removal particle electrode

[0053] The invention provides a new cyanide-removing particle electrode capable of effectively removing cyanide ions in industrial wastewater with a cyanide ion concentration of 2000-3000 mg / L (high-concentration cyanide-containing wastewater in the industry).

[0054] The particle electrode for removing cyanide is composed of foam metal, metal salt and binder.

[0055] The foamed metal is used as the substrate of the particle electrode for removing cyanide, and there are many three-dimensional network holes evenly distributed thereon. The metal salt is used as a catalyst, and the binder uniformly consolidates the metal salt on the surface of the foam metal and the inner surface of the three-dimensional network holes.

[0056] The metal foam can be nickel foam, copper foam or titanium foam. These metal foams not only have numerous three-dimensional network holes, but also can be produced according to the size of the three-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com