3D printer with function of continuous feeding

A 3D printer and printer technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve problems affecting the continuity of printing work, affecting the efficiency of work, etc., to prevent interruptions, improve efficiency, and facilitate use and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

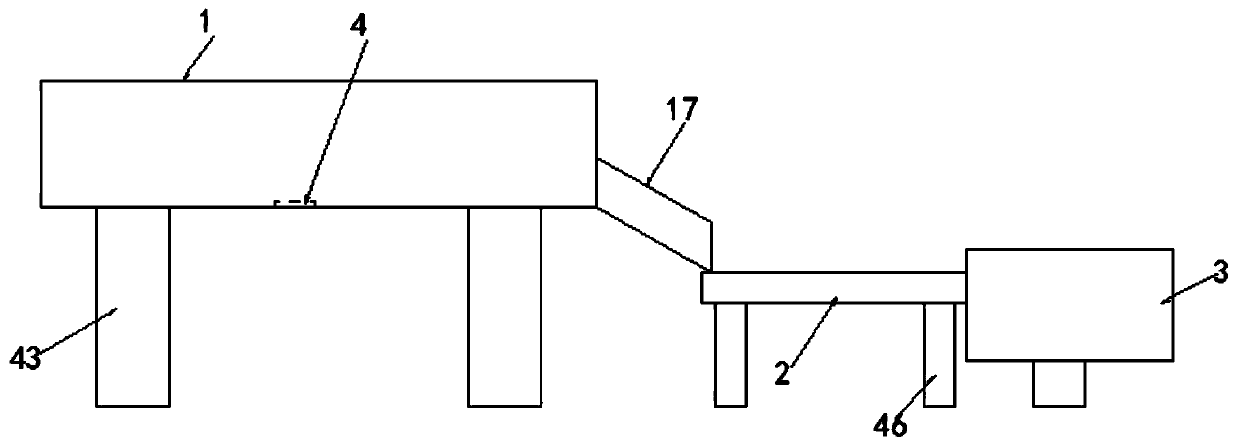

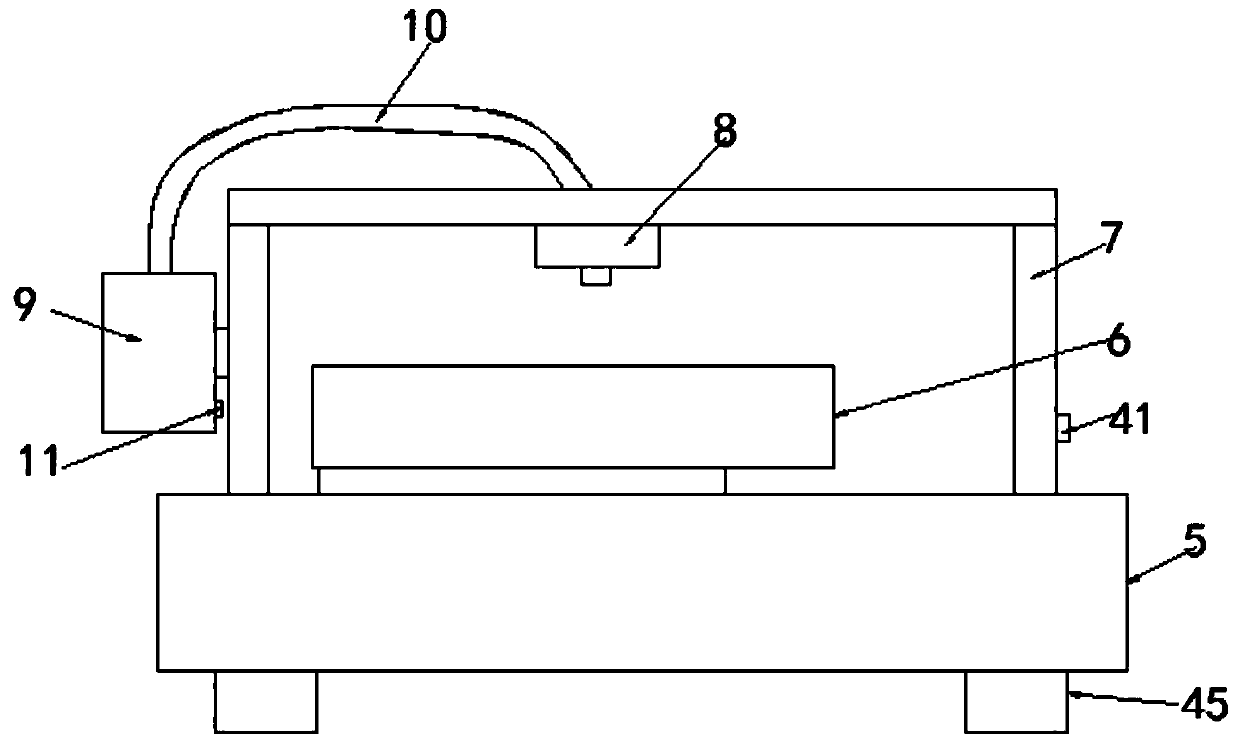

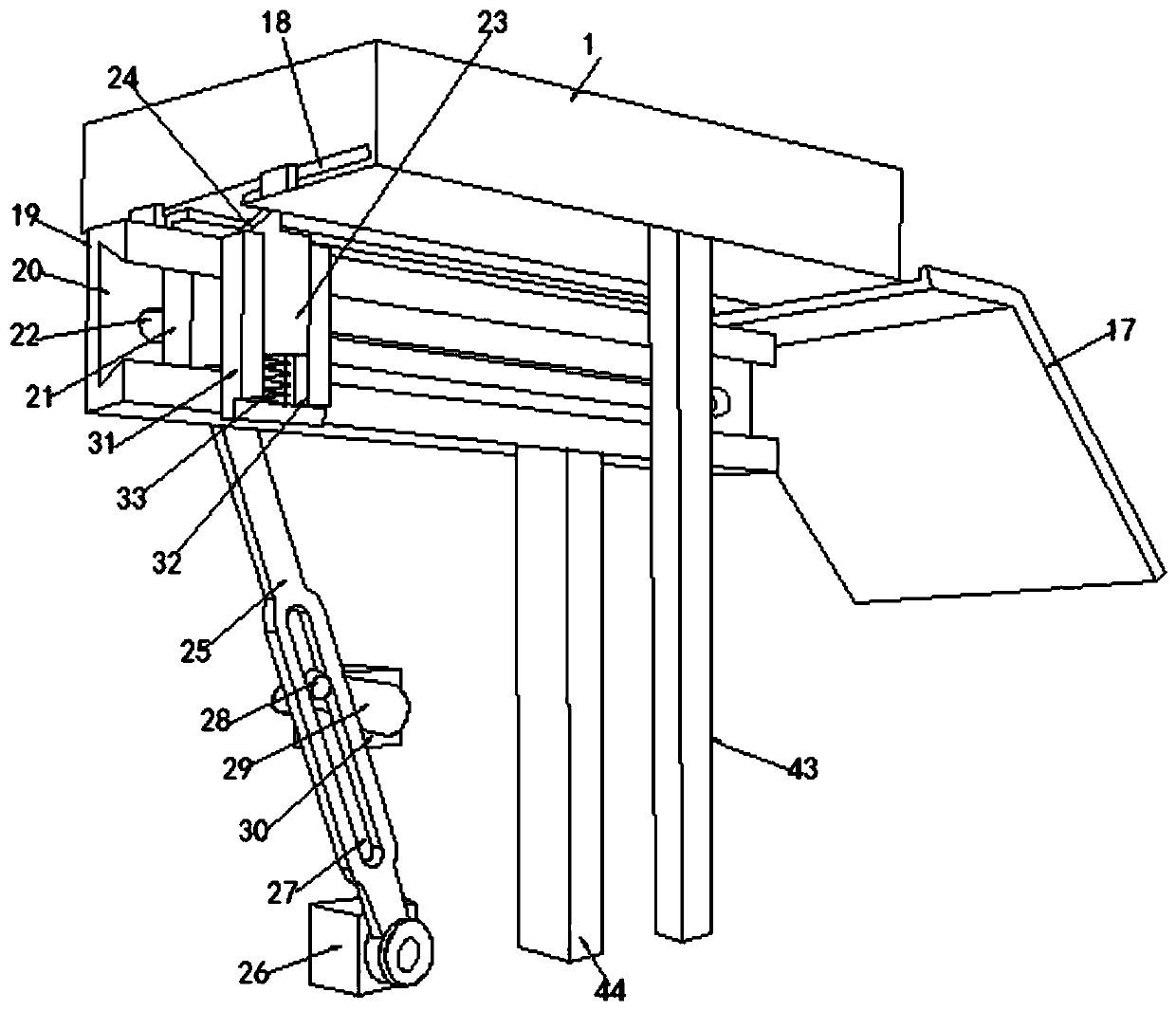

[0028] Embodiment one, such as Figure 1-4 As shown, a 3D printer with a continuous feeding function according to an embodiment of the present invention includes a storage box 1, and the storage box 1 is a cuboid storage box 1, which can store the tray to ensure subsequent supply and fixation. Table 2 and printer body 3, the fixed table 2 is fixed on one side of the printer body 3, the fixed table 2 is used to transport the feed wire 10 to the feed tray 9, and the fixed table 2 is far away from the printer body 3 One side of the storage box 1 is fixed, and the storage box 1 guarantees the supply of subsequent goods, and prevents temporary search and handling when replenishing goods. The inside of the storage box 1 is fixed with a gravity sensor 4, which can be used in time. Detect the internal material tray, so as to ensure the supply and delivery of the material tray. The printer body 3 includes a base 5, a processing table 6, a fixed frame 7, a nozzle 8, a feeding tray 9 and...

Embodiment 2

[0029] Embodiment two, such as image 3 As shown, the clamping plate 23 and the sliding plate 21 are fixed by a connecting plate 31, and the middle part of the connecting plate 31 is provided with a clamping groove 32 suitable for the clamping plate 23, and the clamping plate 23 The bottom end is fixed to the inner bottom end of the connecting plate 31 through the spring 33; the spring 33 can support and buffer the clamping plate 23, which is more conducive to the use of the clamping plate 23.

Embodiment 3

[0030] Embodiment three, such as image 3 As shown, ribs are fixed on both sides of the inclined conveying platform 17; the ribs are more conducive to the safety of the tray and prevent slipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com