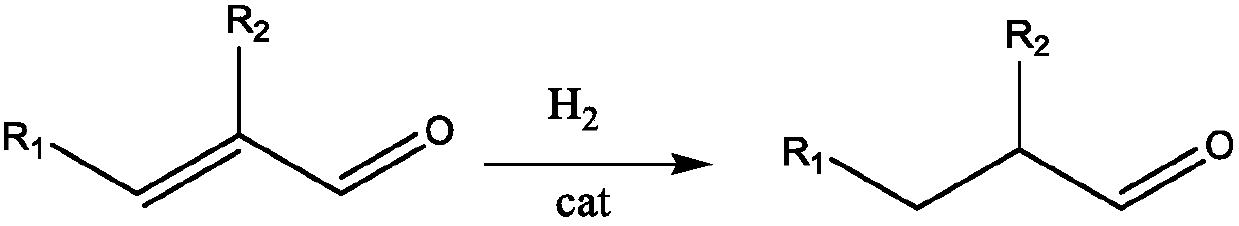

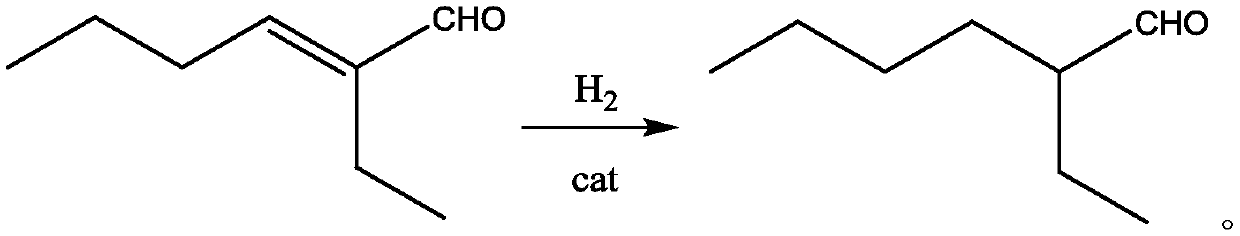

Hydrogenation catalyst, preparation method thereof, and application method of hydrogenation catalyst in alpha, beta-unsaturated aldehydes hydrogenation preparation of saturated aldehydes

A catalyst and unsaturated technology, applied in the field of fine chemicals, can solve the problems of poor stability of isooctene aldehyde, low conversion rate of raw materials, affecting catalyst properties, etc., and achieve the effects of catalyst stability, good dispersibility and good activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0079] Fill the catalyst 1 in the fixed bed reactor, the catalyst filling volume is 100ml, the reaction pressure is 1.6MPa, the temperature is 90°C, and the raw material feeding space velocity is 0.16h -1 , the hydrogen aldehyde molar ratio is 3, the conversion rate of raw materials is 99.6%, the selectivity of isooctylaldehyde is 94.3%, the selectivity of isooctyl alcohol is 3%, and the rest are polymerization high boiling point products.

Embodiment 3

[0081] Fill the catalyst 2 in the fixed bed reactor, the catalyst filling volume is 100ml, the reaction pressure is 2.0MPa, the temperature is 95°C, and the raw material feeding space velocity is 0.18h -1 , the hydrogen aldehyde molar ratio is 4, the conversion rate of raw materials is 99.5%, the selectivity of isooctylaldehyde is 93.5%, the selectivity of isooctyl alcohol is 4.7%, and the rest are polymerization high boiling point products.

Embodiment 4

[0083] Fill the catalyst 3 in the fixed bed reactor, wherein the catalyst filling volume is 100ml, the reaction pressure is 2.0MPa, the temperature is 105°C, and the raw material feeding space velocity is 0.20h -1 , the hydrogen aldehyde molar ratio is 2.5, the conversion rate of raw materials is 99.6%, the selectivity of isooctylaldehyde is 95.6%, the selectivity of isooctyl alcohol is 2.6%, and the rest are polymerized high boiling point products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com