A kind of preparation method of microcapsules with double-layer coating structure and the prepared microcapsules

A double-layer coating and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., can solve the problems of limited repair ability and difficult to meet the needs of coating repair, and achieve strong crack propagation ability and enhanced structure Acid corrosion resistance and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

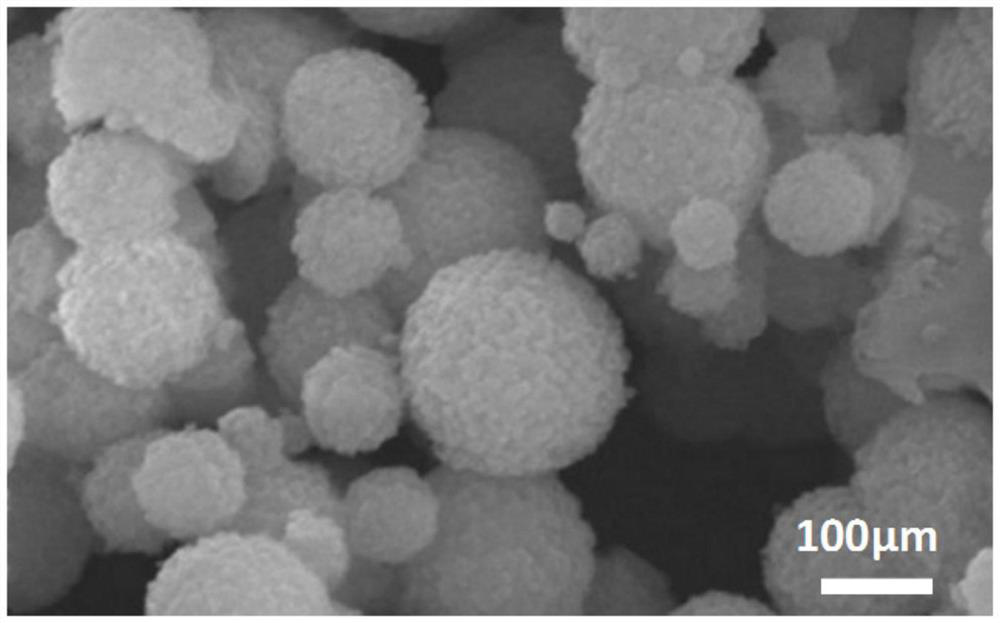

[0072] Preparation of microcapsules with double-layer coating structure

[0073] (1) Polystyrene / coated tung oil

[0074] Weigh 0.05g of initiator AIBN and add it to 12g of styrene (ST), stir thoroughly in a round bottom flask, then heat in a water bath at 80°C for 1.5h, and cool to room temperature for use. Weigh 5g of tung oil, add 1g of emulsifier sodium dodecylbenzenesulfonate, add 20g of deionized water, add 10g of the above-mentioned PS prepolymer, adjust the stirring rate, and emulsify and disperse the mixed solution in a three-necked flask for 10min to obtain a uniform emulsion . Add 0.5g resorcinol to the obtained emulsion, slowly raise the temperature to 60°C, and react for 2.5h. After the end, cool the microcapsule mixture to room temperature, wash the microcapsules with a mixed solution of ethanol and water and suction filter, and dry the product at low temperature .

[0075] (2) Polystyrene / polyaniline / tung oil

[0076]First, 0.466g of aniline was added to wat...

Embodiment 2

[0084] Preparation of microcapsules with double-layer coating structure

[0085] (1) Polystyrene / coated tung oil

[0086] Weigh 12g of styrene (ST) into a flask, add 0.06g of initiator AIBN, stir well, heat in a water bath at 80°C for 1.5h, cool to room temperature at 26°C, and set aside to obtain PS prepolymer. Weigh 5g of tung oil into a three-necked flask, add 1g of emulsifier sodium dodecylbenzenesulfonate, add 20g of deionized water, add 5g of the above PS prepolymer, adjust the magnetic stirring speed to 200r / min, and make the mixed solution in the three-necked flask Emulsify and disperse in the flask for 10 minutes to obtain a uniform emulsion. Add 0.5g resorcinol to the obtained emulsion, slowly heat up to 60°C at a rate of 2°C / min, and react for 2.5h. After the end, cool the microcapsule mixture to room temperature 26°C, wash the microcapsules with 60v% ethanol aqueous solution and pump Filter, and vacuum-dry the product at 45°C to obtain polystyrene / coated tung oil...

Embodiment 3

[0100] A method for preparing microcapsules with a double-layer coating structure, comprising the following steps:

[0101] (1) Polystyrene / coated linseed oil, tung oil

[0102] Weigh 15g of styrene (ST) into a flask, add 0.06g of initiator AIBN, stir thoroughly, heat in a water bath at 78°C for 1.5h, cool to room temperature at 26°C, and set aside to obtain a PS prepolymer. Weigh 5g of linseed oil and 5g of tung oil into a three-necked flask, add 1g of emulsifier sodium dodecylbenzenesulfonate, add 30g of deionized water, and stir evenly. Add 2-3 drops of n-octanol dropwise, then add 8g of the above PS prepolymer, adjust the magnetic stirring speed to 200r / min, and emulsify and disperse the mixed solution in a three-necked flask for 20min to obtain a uniform emulsion. Add 0.6g resorcinol to the obtained emulsion, slowly heat up to 65°C at a rate of 3°C / min, and react for 2 hours. After the end, cool the microcapsule mixture to room temperature 26°C, wash the microcapsules wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com