Preparation method of medical foam dressing with slow-release antibacterial effect

A foam, sustained-release technology, applied in medical science, absorbent pads, bandages, etc., can solve the problems of secondary wounds, dressing adhesion, discoloration, etc., achieve good biocompatibility, good antibacterial properties, and promote wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

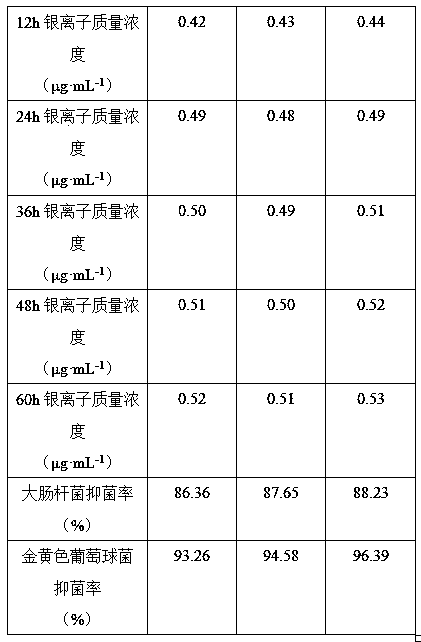

Embodiment 1

[0030] In terms of parts by weight, 10 parts of chitosan fiber, 1 part of 0.05mol / L silver nitrate solution, 0.8 part of 0.2mol / L sodium borohydride solution, 50 parts of deionized water were weighed respectively, and the chitosan fiber and deionized Mix ionic water evenly to obtain a dispersion, add 0.05mol / L silver nitrate solution to the dispersion, and stir magnetically for 10 minutes at a stirring speed of 800r / min to obtain a mixture, add 0.2mol / L boron to the mixture Sodium hydride solution, continue stirring for 1 hour, filter to obtain the filter residue, wash the filter residue twice with deionized water to obtain the silver-loaded fiber; mix zinc acetate dihydrate, sodium hydroxide and absolute ethanol in a mass ratio of 1:1:5 Mix, heat and stir at a temperature of 70°C and a stirring speed of 400r / min for 2h to obtain a reaction solution, soak the sodium alginate fiber in the reaction solution for 10min, take it out and dry it in an oven at a temperature of 50°C for...

Embodiment 2

[0032] In parts by weight, 15 parts of chitosan fiber, 2 parts of 0.05mol / L silver nitrate solution, 0.9 part of 0.2mol / L sodium borohydride solution, 55 parts of deionized water were weighed respectively, and chitosan fiber and deionized Mix the ionic water evenly to obtain the dispersion liquid, add 0.05mol / L silver nitrate solution to the dispersion liquid, and stir magnetically for 13min at a stirring speed of 850r / min to obtain the mixed liquid, add 0.2mol / L boron to the mixed liquid Sodium hydride solution, continue to stir for 1.5h, filter to obtain the filter residue, wash the filter residue 3 times with deionized water, and obtain the silver-loaded fiber; zinc acetate dihydrate, sodium hydroxide and anhydrous Mix ethanol, heat and stir at a temperature of 75°C and a stirring speed of 450r / min for 2.5h to obtain a reaction solution, soak the sodium alginate fiber in the reaction solution for 11min, take it out and place it in an oven at a temperature of 55°C Dry for 5 ...

Embodiment 3

[0034] In parts by weight, 20 parts of chitosan fiber, 3 parts of 0.05mol / L silver nitrate solution, 1.0 part of 0.2mol / L sodium borohydride solution, 60 parts of deionized water were weighed respectively, and chitosan fiber and deionized Mix ionic water evenly to obtain a dispersion, add 0.05mol / L silver nitrate solution to the dispersion, and stir magnetically for 15 minutes at a stirring speed of 900r / min to obtain a mixture, add 0.2mol / L boron to the mixture Sodium hydride solution, continue to stir for 2 hours, filter to obtain the filter residue, wash the filter residue 4 times with deionized water, and obtain the silver-loaded fiber; mix zinc acetate dihydrate, sodium hydroxide and absolute ethanol in a mass ratio of 1:1:5 Mix, heat and stir at a temperature of 80°C and a stirring speed of 500r / min for 3h to obtain a reaction solution, soak the sodium alginate fiber in the reaction solution for 12min, take it out and dry it in an oven at a temperature of 60°C for 6h , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com