Operation monitoring platform for medium-frequency electric furnace

A technology for operation monitoring and intermediate frequency electric furnaces, which is applied in the direction of furnaces, crucible furnaces, furnace components, etc., can solve the problems of difficult prediction and deployment of electric furnace operation, low operating capacity and valley value of the main transformer, high peak value of total operating power, etc., to achieve shortening The effect of reducing downtime, reducing work intensity, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

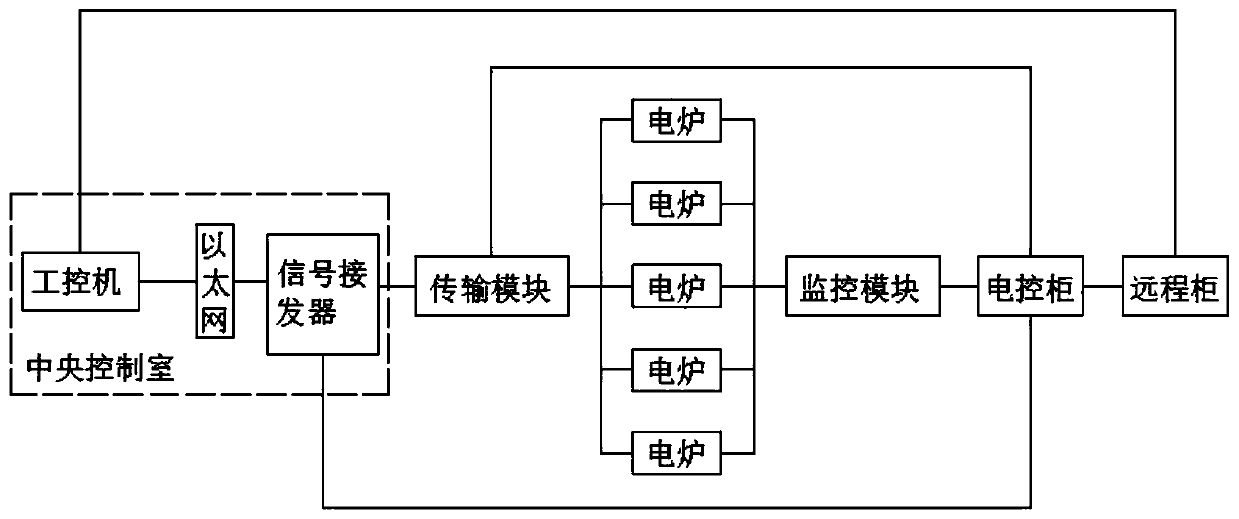

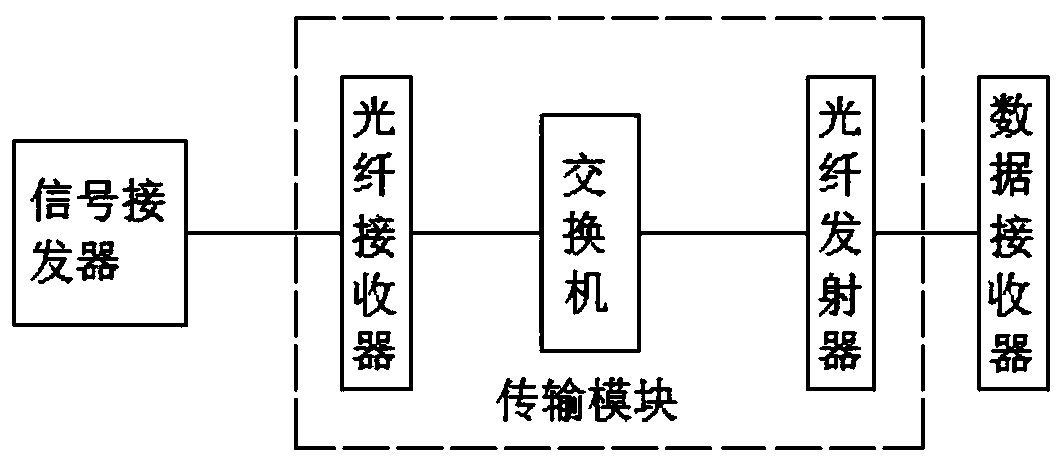

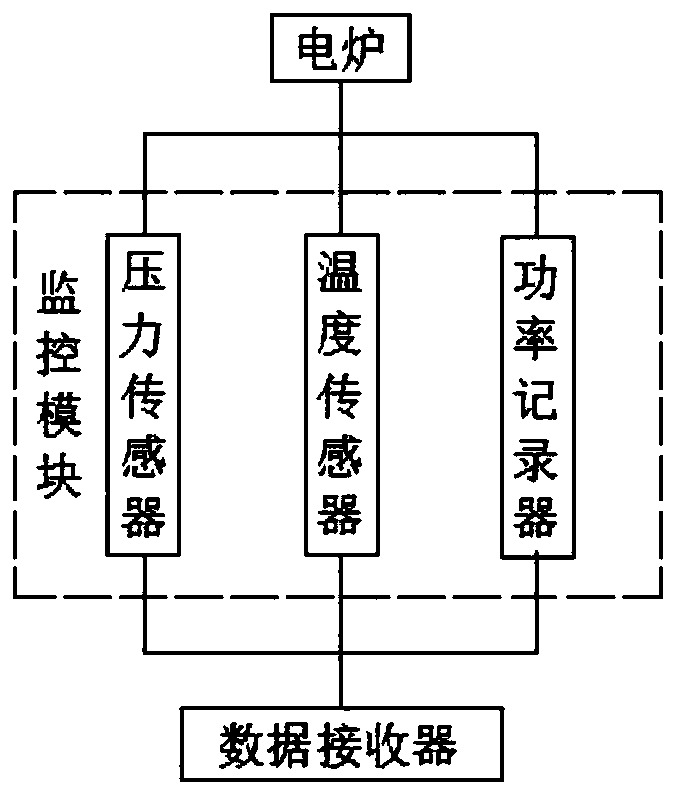

[0019] refer to Figure 1-5 , an intermediate frequency electric furnace operation monitoring platform, including a central control room and a plurality of electric furnaces, the central control room is connected to a transmission module through a signal connection, and the transmission module includes a fiber optic receiver and a fiber optic transmitter, wherein the fiber optic receiver and the fiber optic transmitter The electrical balance between them is connected to the switch, and the optical fiber receiver and the signal receiver are connected by signals. The central control room includes the industrial computer and the signal transmitter, and the signal transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com