Evaluation method suitable for underground coal mine gas extraction drilled hole sealing quality detection

A gas extraction and evaluation method technology, applied in construction and other directions, can solve the problems of drilling failure, single classification, high drilling construction cost, etc., and achieve the effect of improving utilization efficiency, scientific indicators, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

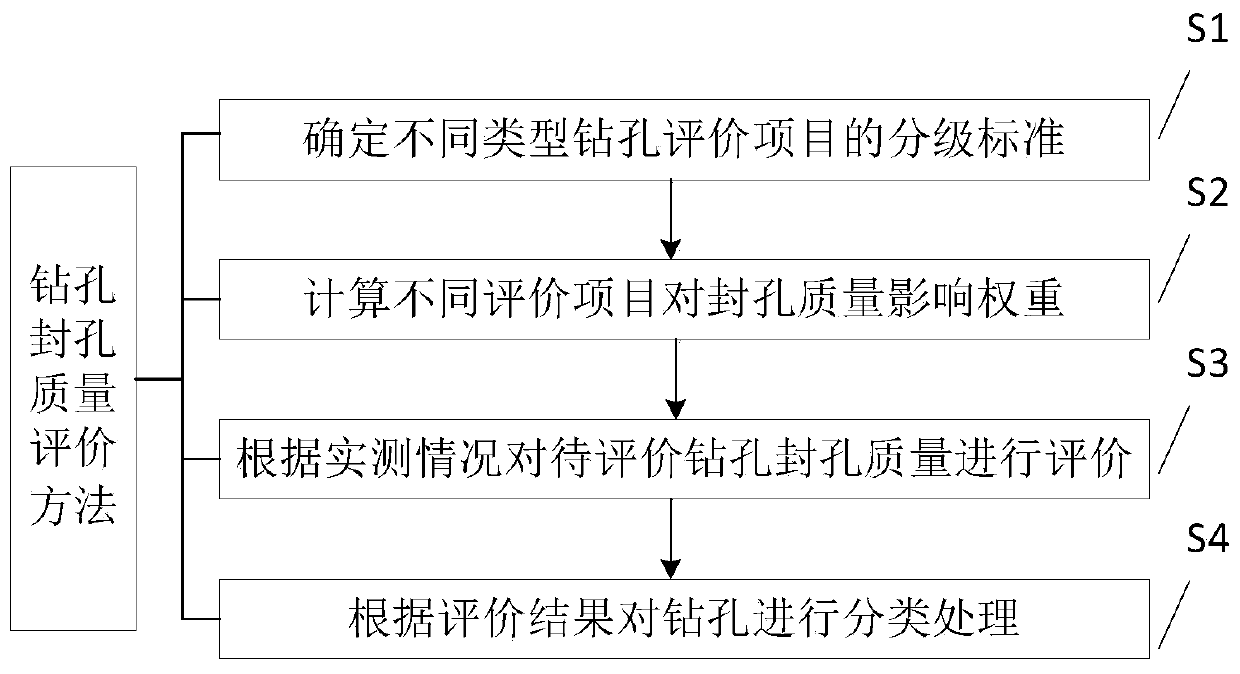

[0023] Such as figure 1 Shown, the present invention comprises the steps:

[0024] S1 Determine the grading standards for different types of drilling evaluation items,

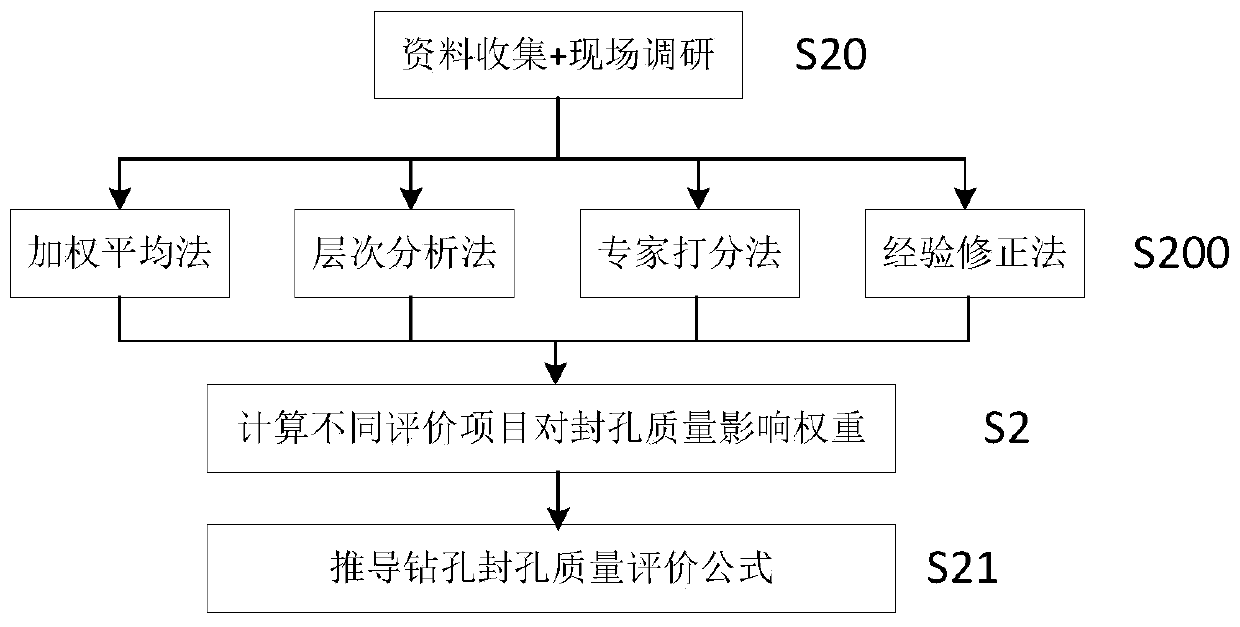

[0025] S2 calculates the impact weight of different evaluation items on the sealing quality;

[0026] S3 Evaluate the sealing quality of the drill hole to be evaluated according to the actual measurement;

[0027] S4 performs classification processing on boreholes according to the evaluation results.

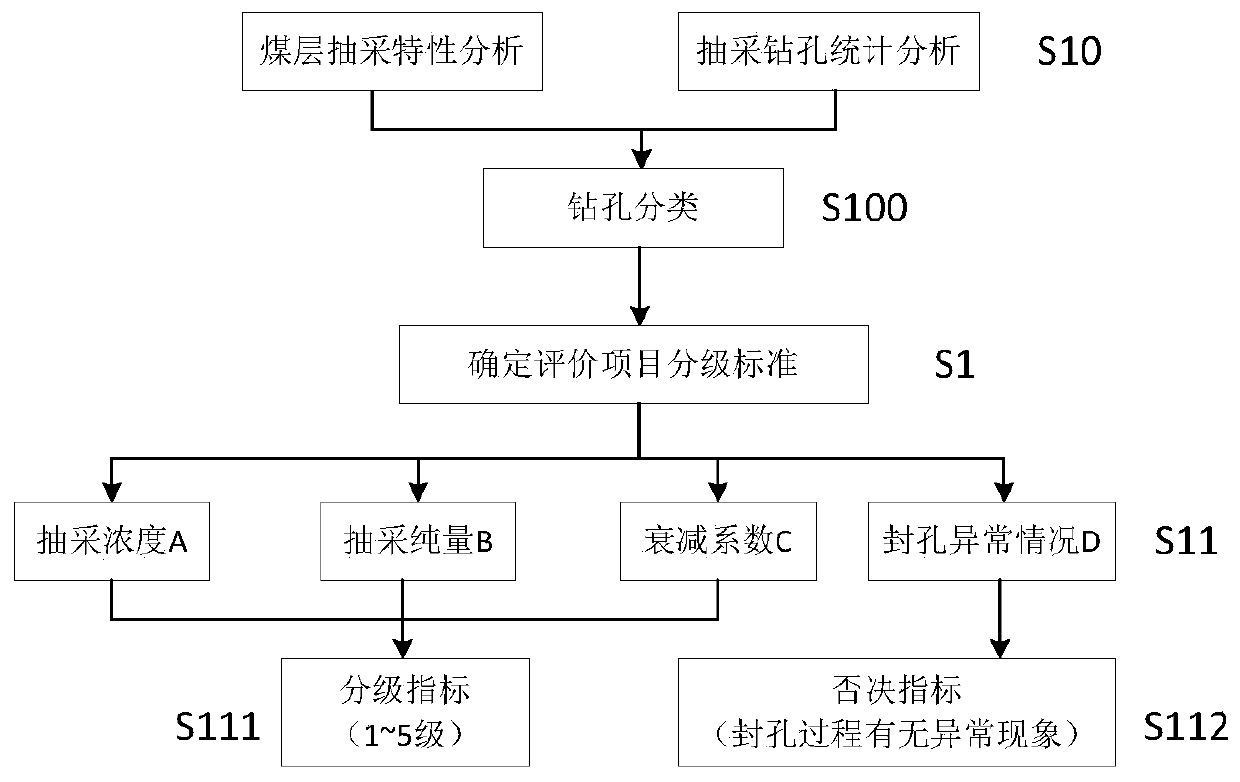

[0028] Such as figure 2 As shown, in step S1, four single-hole evaluation items (drainage concentration A, drainage scalar B, attenuation coefficient C, anomaly D ) classification index, different types of boreholes in coal mines include bed-through drilling or bedding drilling. If there is no abnormal phenomenon in the sealing process, the classification index is determined according to the extraction concentration A, the extraction scalar amount B and the attenuation coefficient C. If there is an abnorma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com