Biomass composite material as well as preparation method and application thereof

A composite material and biomass technology, applied in the field of bio-environmental material preparation, can solve the problems of single heavy metal passivation method, limited passivation performance, damage to soil structure, etc., and achieve the effect of improving soil physical and chemical properties and reducing effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

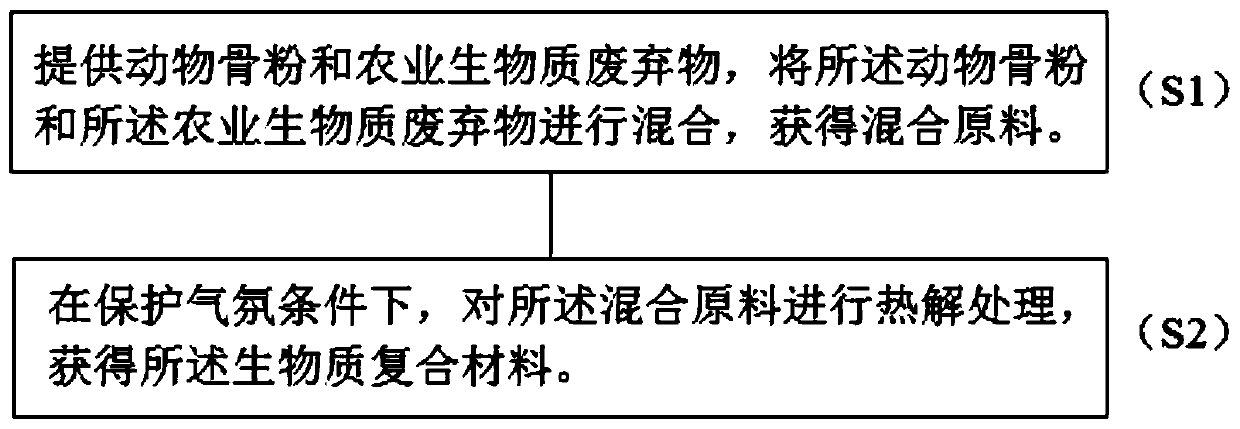

[0030] The embodiment of the present invention provides a kind of preparation method of biomass composite material, see figure 1 ,include:

[0031] S1. Provide animal bone meal and agricultural biomass waste, disperse the animal bone meal and the agricultural biomass waste in water, perform ultrasonic stirring, solid-liquid separation, and dry the obtained solid phase to obtain mixed raw materials.

[0032] The animal bone meal refers to animal waste bones or leftovers from meat product processing that are formed by crushing, mainly animal bones, and the animal bones are bones of common animals, such as: pig bones, beef bones, sheep bones, chicken bones, etc. At least one of bone, duck bone and fish bone. In order to obtain a product with a better adsorption effect, it is preferable to mix the bone powder obtained by pulverizing the bone with agricultural waste.

[0033] The agricultural biomass waste is at least one of bamboo chips, wood chips, straw, bagasse, fruit shells,...

Embodiment 1

[0052] Both the bamboo chips and the pulverized bovine bones were dissolved in water and dispersed, and the mass ratio of the bamboo chips to the bovine bones was controlled to be 1:1 to obtain a suspension. The above suspension was stirred and ultrasonicated, and the ultrasonic time was controlled to be 30 min, the suspension was separated, and then the obtained solid-phase mixed raw material was dried.

[0053] The dried mixed raw materials were subjected to high-temperature pyrolysis under a nitrogen atmosphere. The pyrolysis temperature was controlled at 600°C, and the heating rate was 5°C / min. After reaching the specified 600°C, pyrolysis was continued for 1 hour to obtain pyrolysis products. Wash with water and dry.

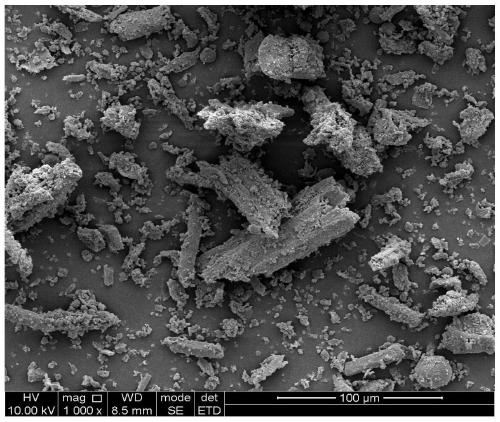

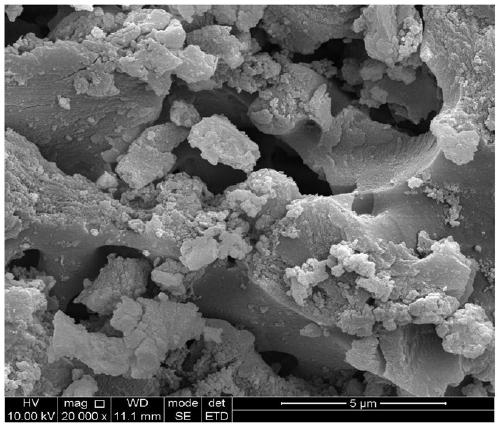

[0054] Scanning electron microscopy (SEM) was used to scan the dried pyrolysis product, and the obtained results were as follows: figure 2 and image 3 shown. from figure 2 and image 3 It can be seen that bamboo charcoal and beef bone charcoal are m...

Embodiment 2~ Embodiment 6

[0059] The preparation methods of the biomass composite materials in Examples 2 to 6 are the same as those in Examples, except for the types, amounts and related process parameters of raw materials, which are listed in Table 1.

[0060] The biomass composite material obtained in each example includes the corresponding char generated by the pyrolysis of the raw material.

[0061] The information of the raw material of table 1 embodiment 2~embodiment 6 and relevant process parameter

[0062]

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com