PETG blow molded bottle matte glass effect color masterbatch and preparation method thereof

A glass effect and color masterbatch technology is applied in the field of PETG bottle blowing matte glass effect color masterbatch and its preparation. The effect of smooth surface, increased production process and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

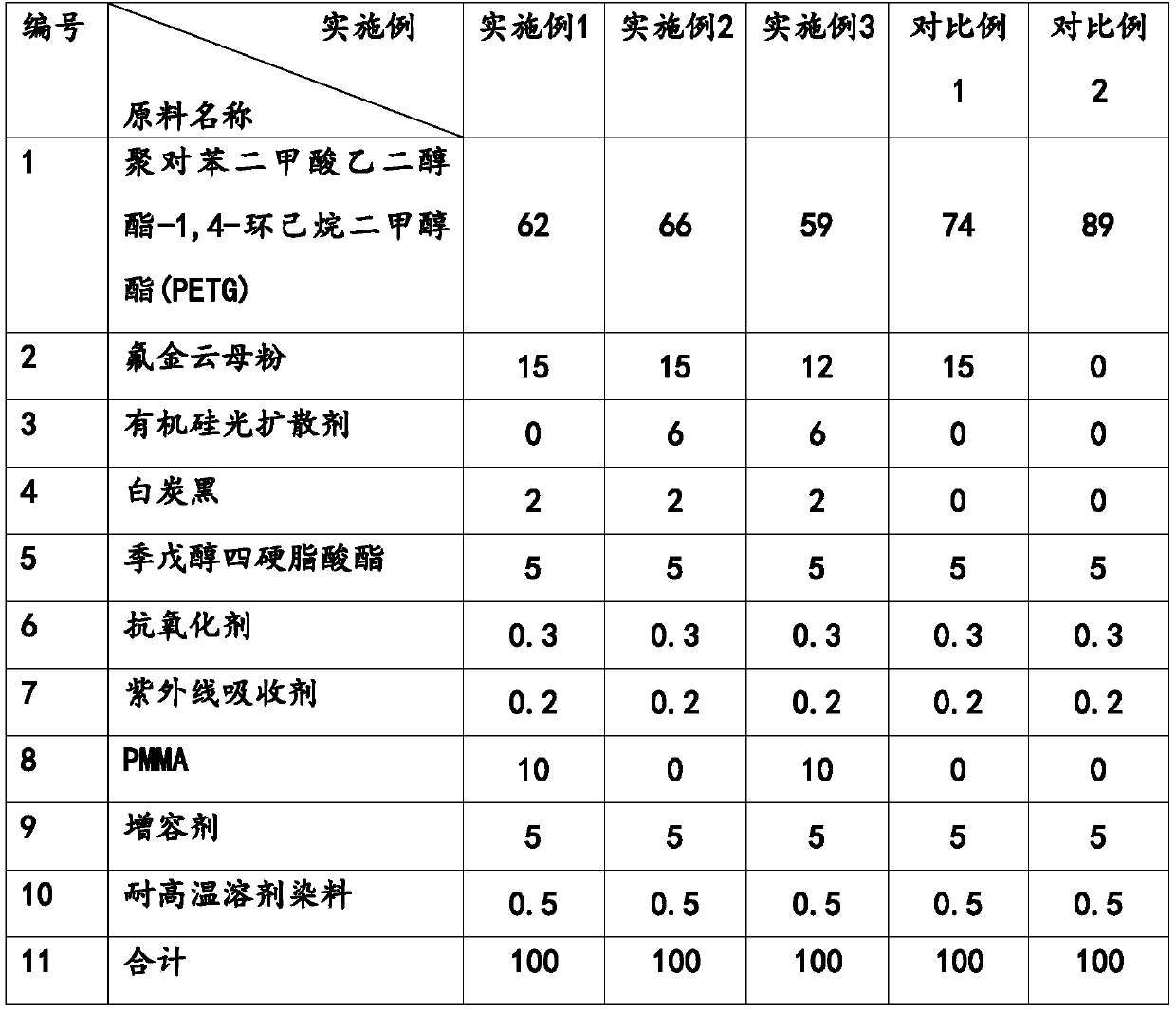

Examples

preparation example Construction

[0050] The preparation method of PETG bottle blowing matte glass effect color masterbatch of the present invention comprises the following steps:

[0051] (1) Dry all raw materials at 80°C for 2 hours for later use;

[0052] (2) Put PETG, white carbon black, and silicone light diffusing agent into a high-speed mixer and mix for 3-10 minutes at a speed of 1200-1500rpm / min, then add fluorphlogopite powder, antioxidant, and UV absorber according to the formula , PMMA and compatibilizer are mixed at a low speed of 400rpm / min for 1 to 3 minutes to obtain a mixed material;

[0053](3) Select a high-speed twin-screw extruder with a screw length-to-diameter ratio of 1:44, set the host speed of the high-speed twin-screw extruder to 450-600rpm / min, and the feeding speed to 350-410rpm / min, set The temperature of the high-speed twin-screw extruder is 190 °C in the first zone, 230 °C in the second area, 240 °C in the third area, 240 °C in the fourth area, 240 °C in the fifth area, 240 °C ...

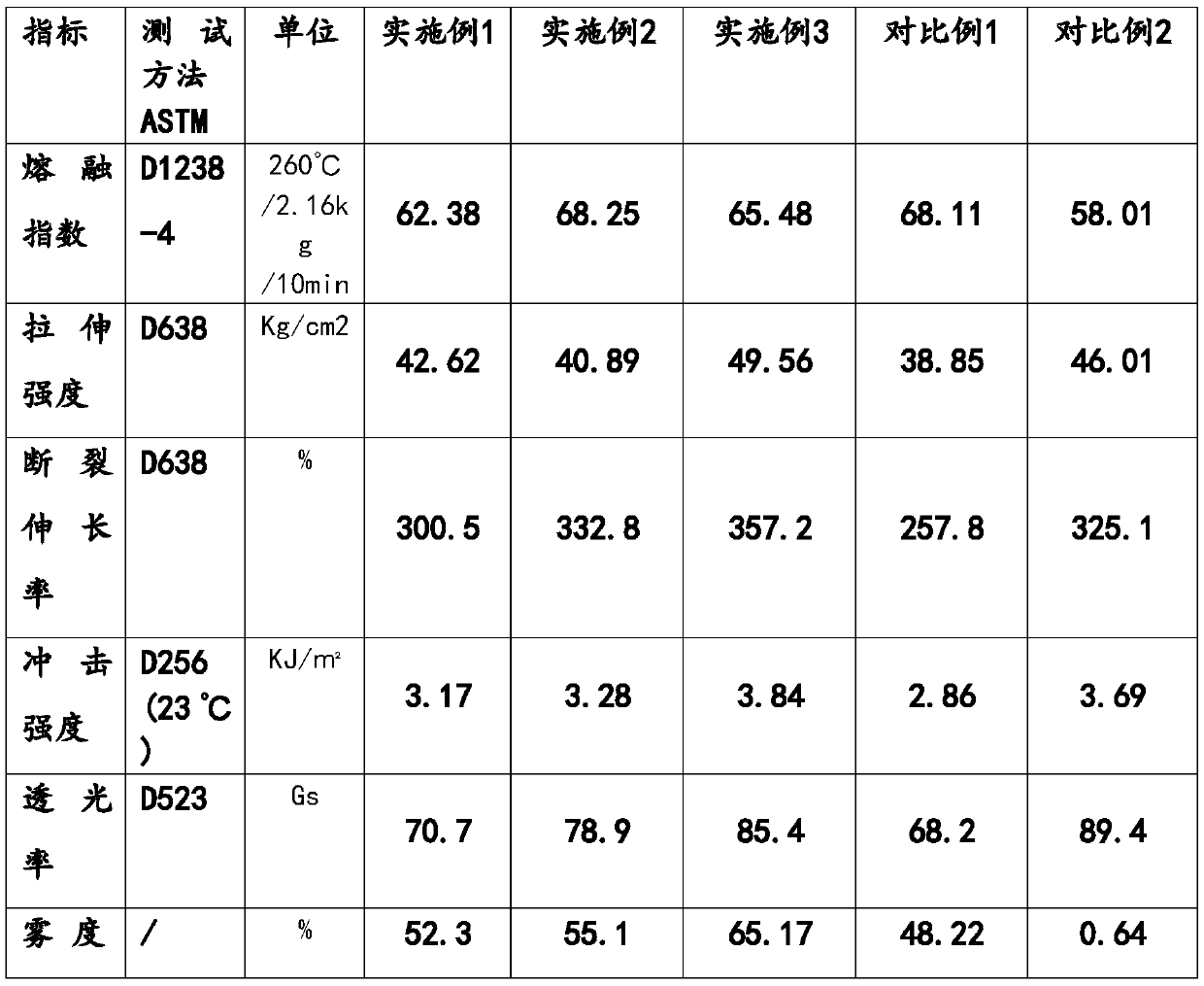

Embodiment 1

[0068] No organic silicon light diffusing agent was added in Example 1, the amount of mica powder was larger than that of Example 3, and the light transmittance and haze were both smaller than that of Example 3.

Embodiment 2

[0069] No PMMA was added in Example 2, resulting in lower light transmittance and haze than Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com