AgGaS2-based intermediate-band semiconductor material and preparation method thereof

A semiconductor and intermediate zone technology, which is applied in the field of AgGaS2-based intermediate zone semiconductor materials and their preparation, can solve the problems of lack of semiconductor materials, inability to meet the use requirements of high-efficiency solar cells, low dispersion, etc., and achieves improved photoelectric conversion efficiency and high degree of automation. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

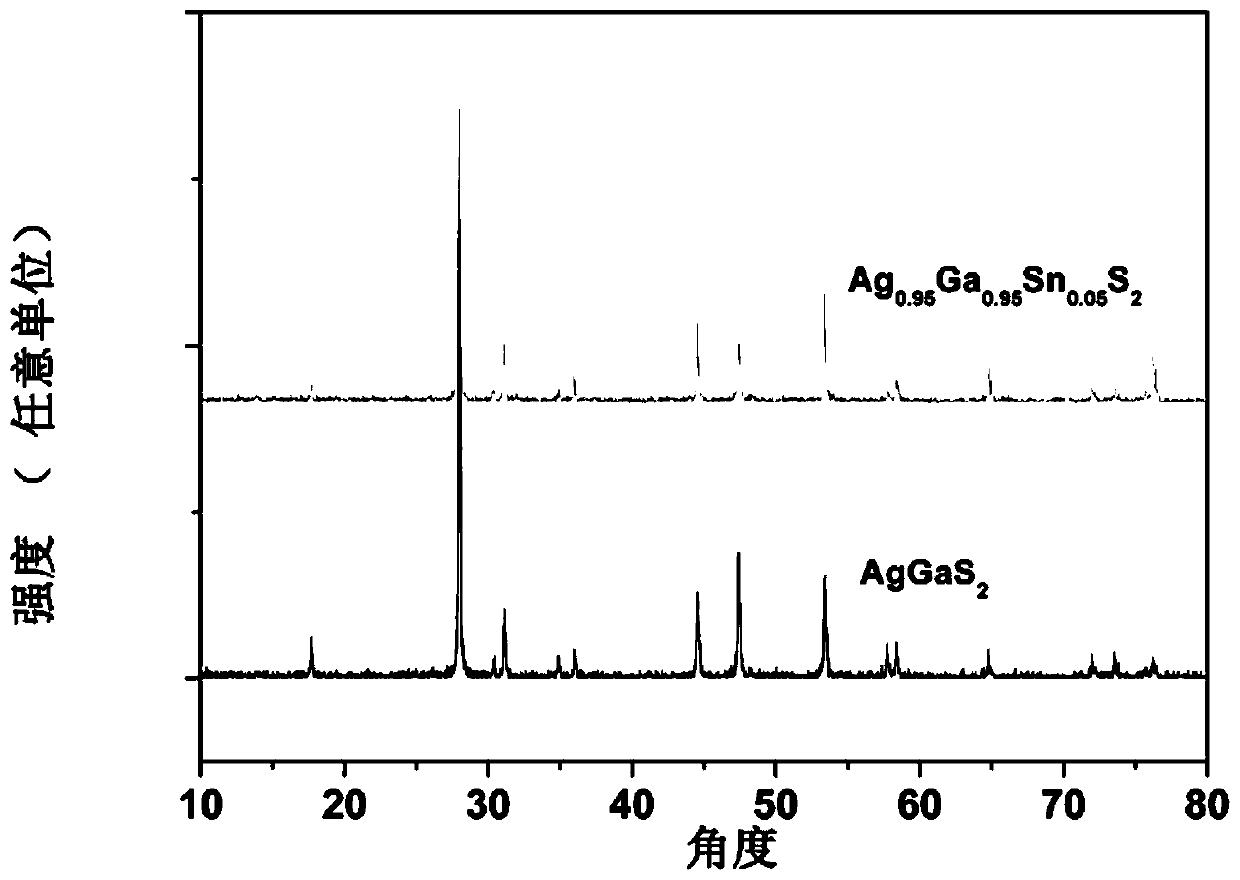

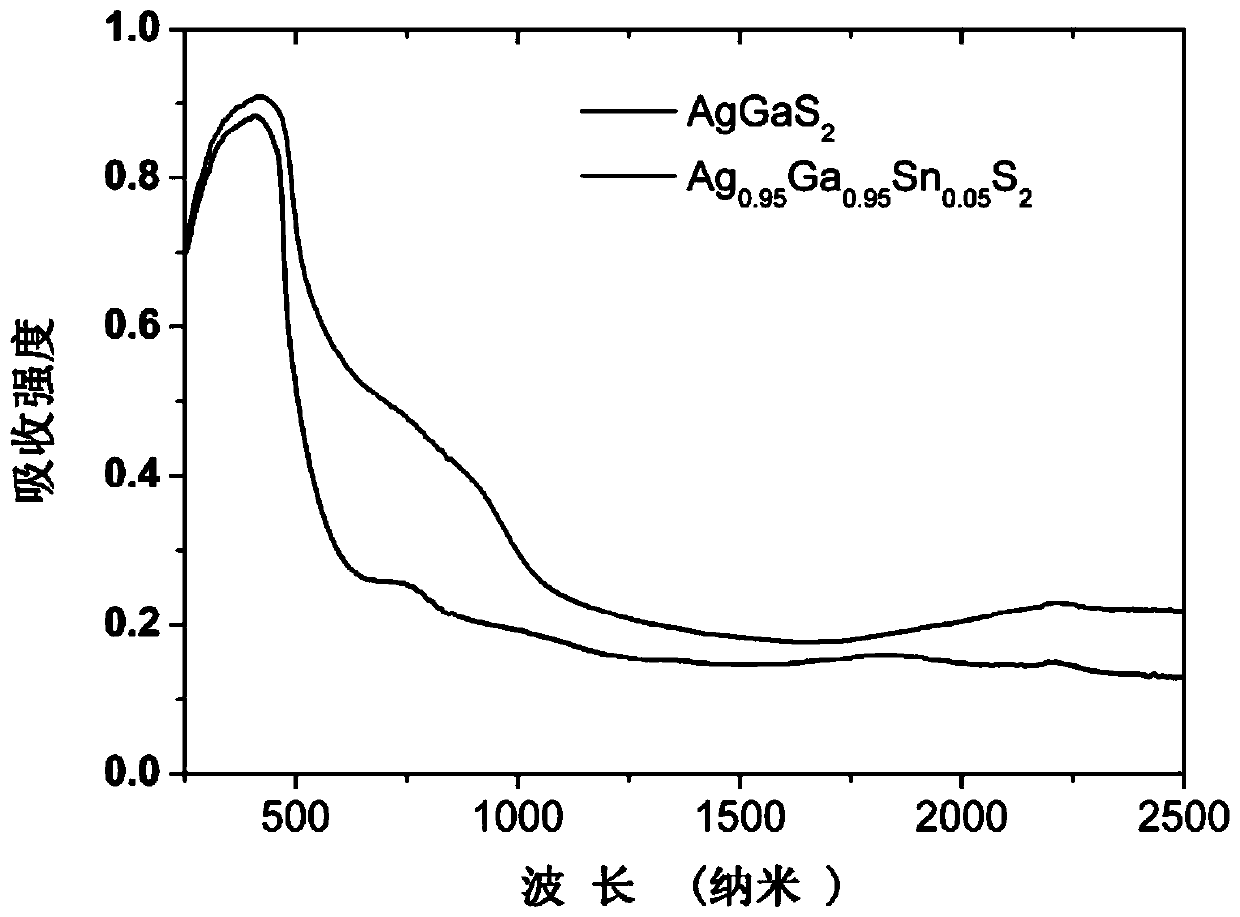

[0031] AgGaS 2 It is a compound with a chalcopyrite structure, and it has a good light-absorbing ability, and is suitable as a parent compound for high-efficiency intermediate-band semiconductor materials. In this embodiment, AgGaS with excellent photoelectric performance 2 It is the parent semiconductor of the intermediate band, and the intrinsic semiconductor AgGaS is doped with the group VI element Sn 2 Ga sites, introducing an intermediate impurity band into the band gap of the intrinsic semiconductor can effectively improve the AgGaS 2 The optical absorption ability makes it have better optical absorption and improves AgGaS 2 Comprehensive performance of semiconductors in the field of solar cells.

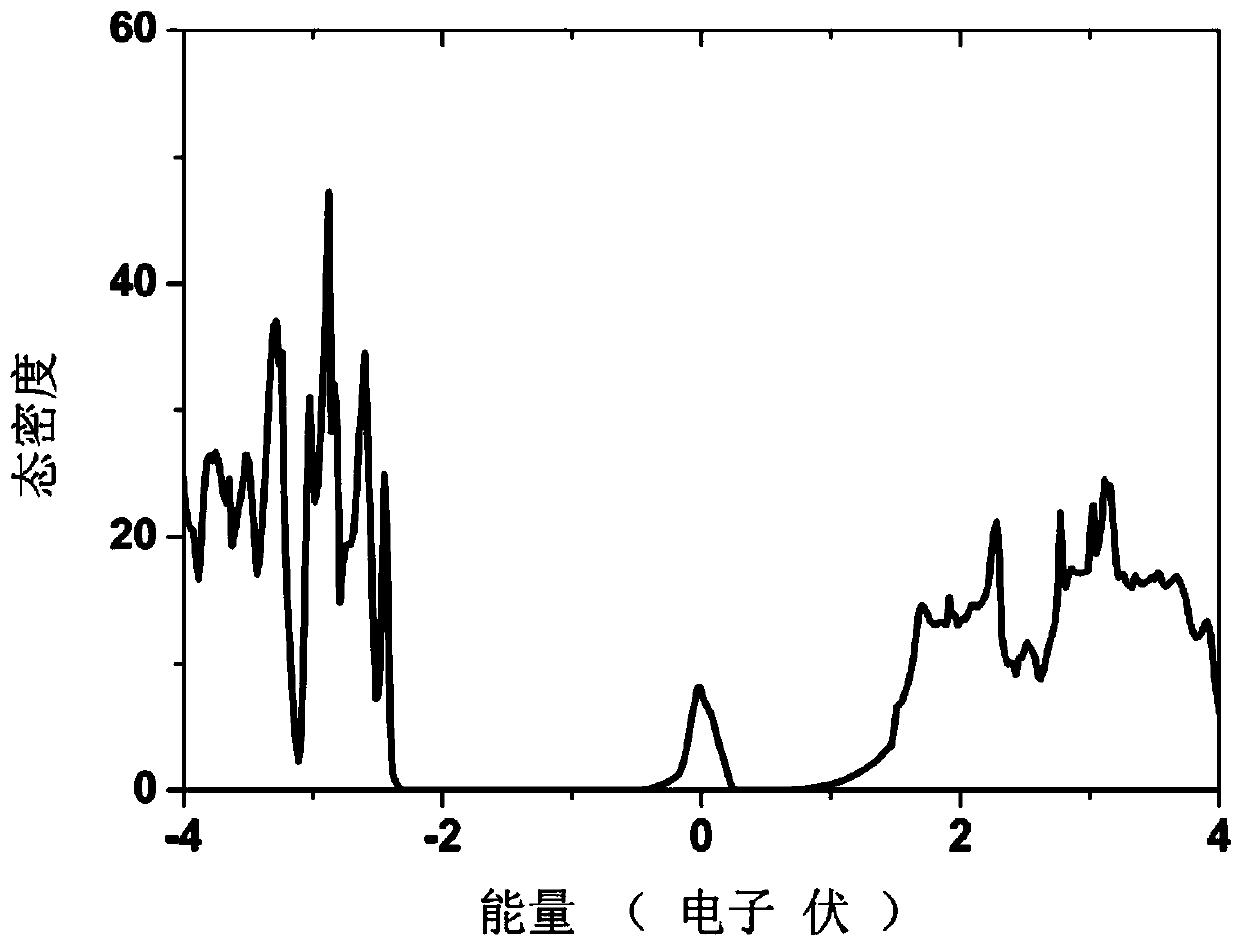

[0032] The electronic density of states was calculated using the first-principles calculation method. AgGaS 2 It is a chalcopyrite structure compound with 16 atoms in the tetragonal unit cell. The doping calculation model adopts a 2×2×2 supercell model, which contains 64...

Embodiment 2

[0046] a AgGaS 2 A method for preparing a base intermediate band semiconductor material, specifically comprising the following steps:

[0047] (1) Ag powder, Ga block, S powder and Sn powder (all with a purity of 5N) are vacuum-packaged in a quartz glass tube according to the stoichiometric ratio;

[0048] (2) Carry out primary sintering of the quartz glass tube, the temperature of the primary sintering is 800° C., and the sintering time is 80 hours. The obtained primary sintered sample is ground and vacuum-packed in the quartz glass tube again;

[0049] (3) The quartz glass tube is subjected to secondary sintering, the temperature of the secondary sintering is 800°C, and the sintering time is 80 hours, and the obtained secondary sintering sample is ground to obtain the product AgGa 1-x sn x S 2 (x=0.01).

[0050] The quartz glass tubes in step (2) and step (3) are sintered in a muffle furnace, and ground in an agate mortar.

Embodiment 3

[0052] a AgGaS 2 A method for preparing a base intermediate band semiconductor material, specifically comprising the following steps:

[0053] (1) Ag powder, Ga block, S powder and Sn powder (all with a purity of 5N) are vacuum-packaged in a quartz glass tube according to the stoichiometric ratio;

[0054] (2) Carry out primary sintering of the quartz glass tube, the temperature of the primary sintering is 900° C., and the sintering time is 60 hours, and the obtained primary sintering sample is ground and vacuum-packed in the quartz glass tube again;

[0055] (3) The quartz glass tube is subjected to secondary sintering, the temperature of the secondary sintering is 900°C, and the sintering time is 60 hours, and the obtained secondary sintered sample is ground to obtain the product AgGa 1-x sn x S 2 (x=0.04).

[0056] The quartz glass tubes in step (2) and step (3) are sintered in a muffle furnace, and ground in an agate mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com