Electric furnace feeding trolley capable of conveniently removing impurities and transporting various different materials

A charging trolley, electric furnace technology, applied in furnaces, furnace components, charge control and other directions, can solve problems such as troubles and affect the production quality of electric furnaces, and achieve the effects of convenient collection, saving charging time, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

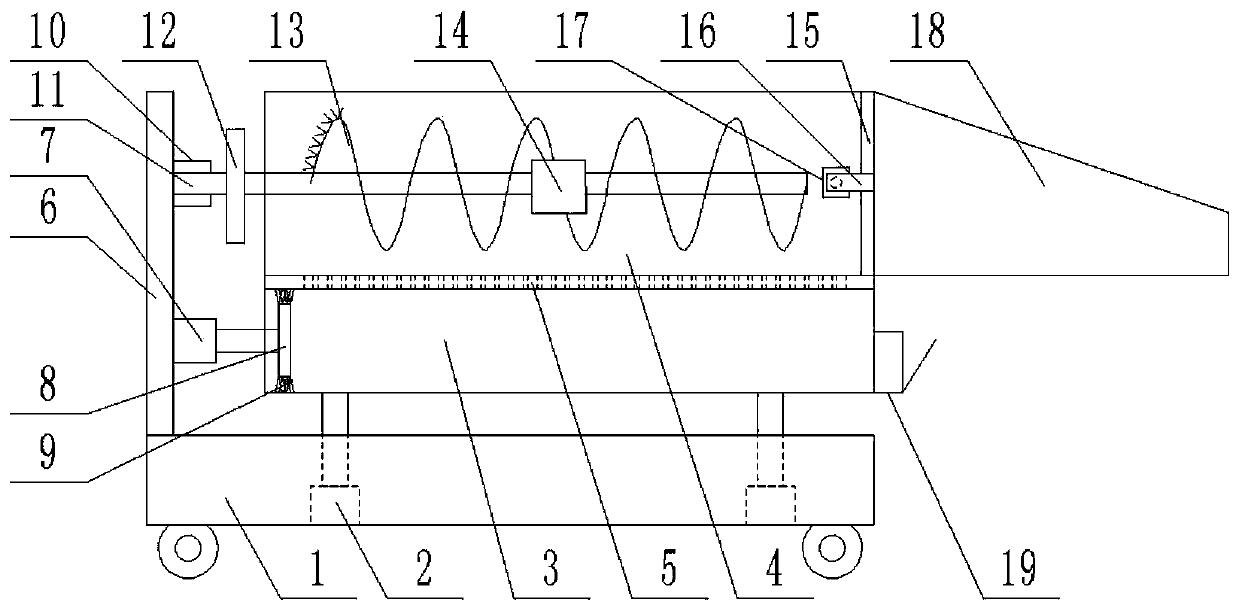

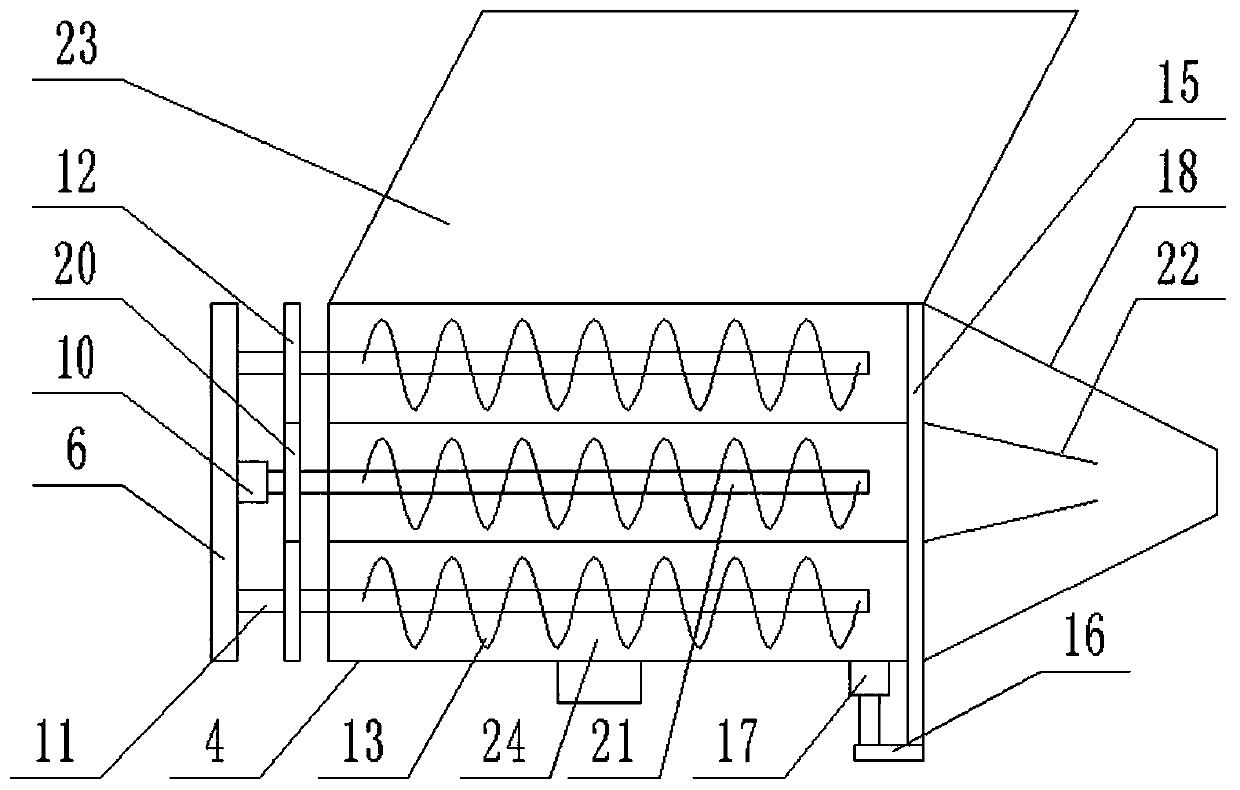

[0017] Such as figure 1 , 2 As shown, an electric furnace feeding trolley that is convenient for removing impurities and transporting various materials at the same time includes a traveling car body 1 and a feeding bin 4, and is characterized in that two ends of the inner bottom of the traveling car body 1 are vertically fixed with electric Cylinder one 2, the top of the piston rod of the electric cylinder one 2 is hinged with a miscellaneous bin 3, the top of the miscellaneous bin 3 is fixed with a sieve plate 5, and the bottom of the feeding bin 4 is fixedly connected with the top of the sieve plate 5 , the sieve plate 5 is provided with some through holes, the top of the miscellaneous collection bin 3 and the bottom of the feeding bin 4 are provided with some circular holes corresponding to the through holes, the feeding bin 4 and the miscellaneous collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com