Pneumatic impact reamer and reaming construction process

The technology of hole reamer and air guide hole is applied in the field of reamer, which can solve the problems of increasing the cost of mud use, affecting the drilling efficiency of hole reaming, complicated binding structure, etc., so as to improve the effect of hole cleaning and the efficiency of hole reaming and rock breaking. The effect of improving and high rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

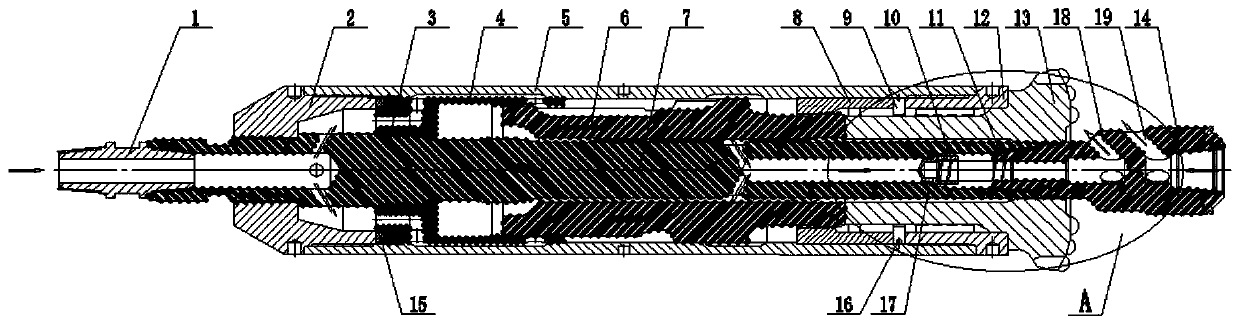

[0028] like Figure 1-2 As shown, a pneumatic impact reamer, the reamer is connected to the drilling machine through the drill pipe, including the upper joint 1, the upper end cover 2, the mandrel 7, the outer cylinder 5, the hammer 6 and the drill bit 13, and the upper joint 1 adopts a conversion buckle Type upper joint 1, the upper joint 1 is connected with the air supply end, the upper joint 1 is connected with the mandrel 7, the mandrel 7 is located on the central axis of the outer cylinder 5, the upper end cover 2 is connected with the mandrel 7 and the outer cylinder 5 through threads, and the outer cylinder 5 is successively fitted with a support sleeve 3 and a bushing 4, the hammer 6 is set inside the bushing 4, the outer cylinder 5 and the spacer 8, the bushing 4 and the spacer 8 are respectively located at both ends of the hammer 6, and the drill bit 13 passes through The spline sleeve 12 is fixedly installed inside the outer cylinder 5, and the drill bit 13 is locat...

Embodiment 2

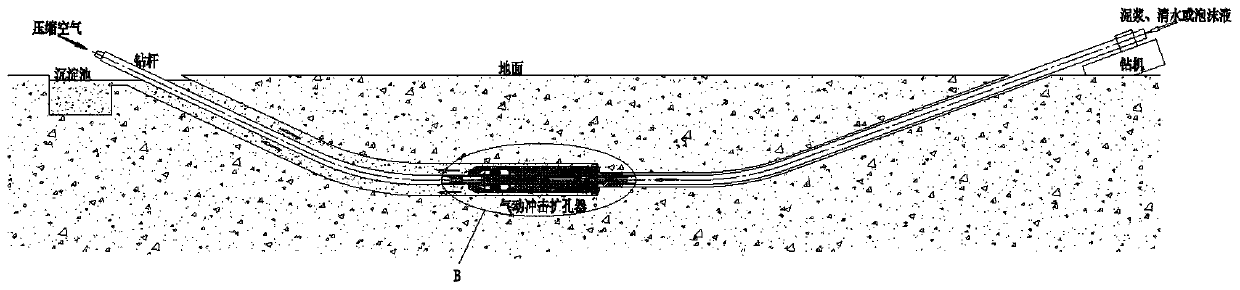

[0036] like Figure 3-4 As shown, a chip removal and reaming process in a drill pipe with a pneumatic impact reamer mainly uses a pneumatic percussion reamer described in Example 1 to realize the chip removal and reaming process in a drill pipe. The specific implementation process is as follows:

[0037] A plurality of air guide holes 18 and liquid guide holes 19 are set on the mandrel 7 of the reamer or the righting joint 14, as the passage for gas and liquid to enter the drill hole; the pneumatic impact reamer (abbreviated as reamer) is used for the pilot hole Reaming construction after the construction is completed. After the construction of the pilot hole is completed, the pilot drill bit is removed, and the liquid delivery end of the reamer is connected to the drill pipe connected to the pilot bit before. The air supply end is also connected to the drill pipe, and the air supply end is drilled The rod is then connected with the air compressor through a rotary joint and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com