Sleeve pipe for through-wall screw rod, and through-wall assembly applying sleeve pipe

A technology of wall-penetrating screw and sleeve, which is applied in the field of wall-penetrating screw sleeve and wall-penetrating components, which can solve problems such as trouble, low efficiency of sleeve installation, easy slipping of sleeve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

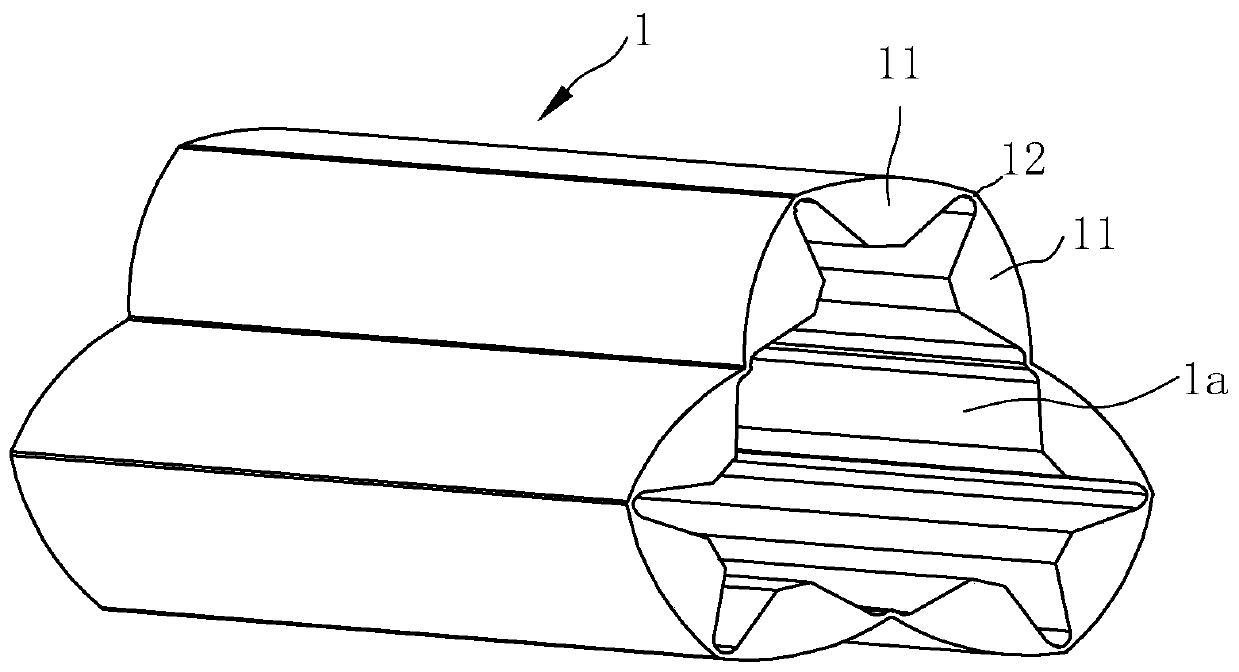

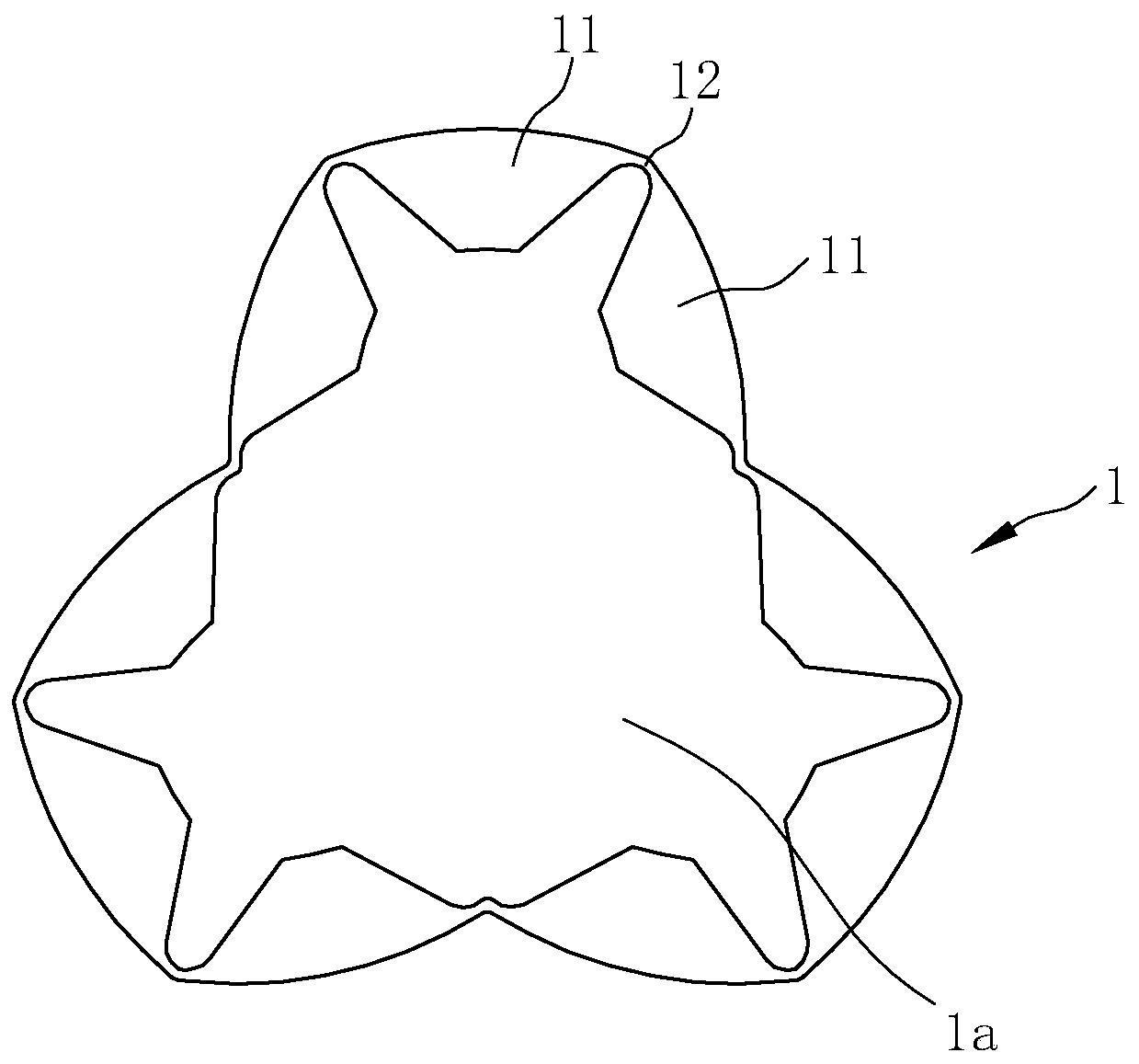

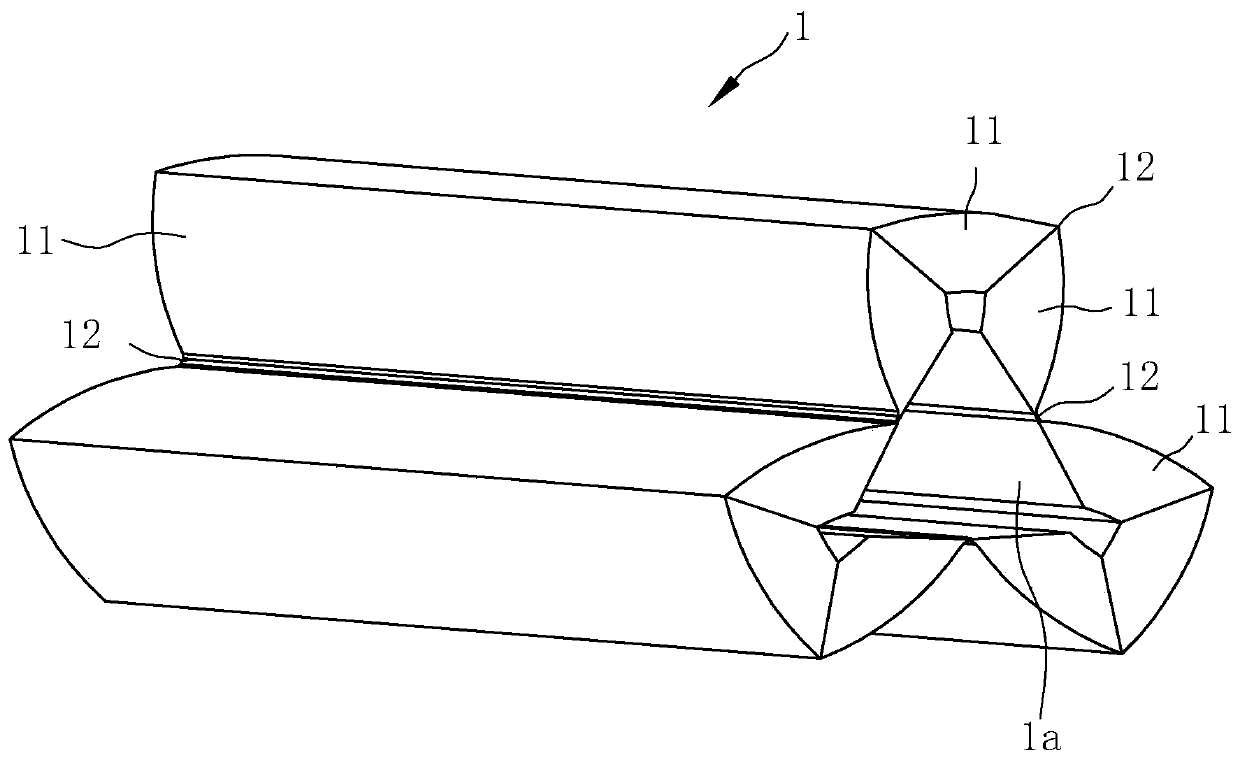

[0058] Such as Figure 1~6 Shown is a preferred embodiment of the bushing for the wall-penetrating screw according to the embodiment of the present invention. The casing for the wall-penetrating screw includes an integrally formed pipe body 1, which is provided with a perforation 1a extending axially through the pipe body 1, and the radial dimension of the pipe body 1 can be adjusted;

[0059] The tubular body 1 has a contracted state formed by shrinking radially inward after being compressed in a natural state. For example, the natural state of the sleeve in this embodiment can be figure 1 with figure 2 state in , the contracted state can be image 3 with Figure 4 state in Figure 5 with Image 6 The state in is the expansion state of the casing; in other embodiments, it can also be Figure 5 with Image 6 is the natural state of the casing, Figure 1 ~ Figure 4 Both are in the contracted state of the casing;

[0060] The pipe body 1 includes a connecting wall 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com