Preparation method of multifunctional printed cotton-containing fabric

A technology for cotton-containing fabrics and cotton fabrics, which is applied in the directions of dyeing, plant fibers, dry-cleaning fiber products, etc., can solve the problems of easy breeding of bacteria, impossibility of cotton-containing fabrics to be soiled, etc. Conducive to long-term use and the effect of purifying the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

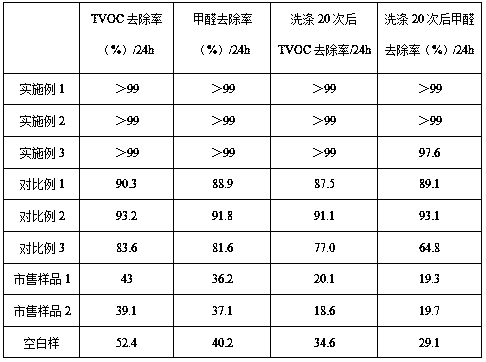

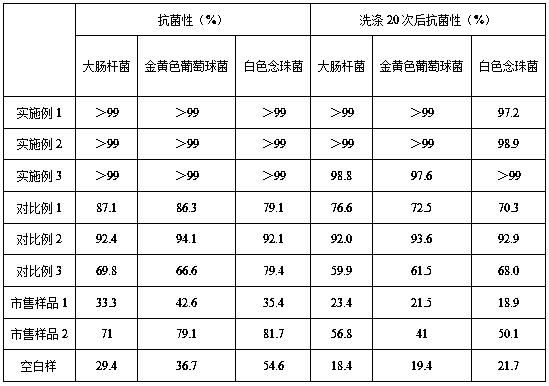

Examples

Embodiment 1

[0032] S1, pre-processing

[0033] Desizing, using enzyme desizing method for desizing treatment, adding 50g of singeed cotton fabric to 1.5L desizing finishing solution (amylase 1.5g, NaCl3g, penetrant 2g), stirring to make it Fully infiltrated, double dipping and second rolling on the padding machine, the liquid retention rate of the cotton fabric is 70%, put it in a steamer after standing for 15 minutes, and steam it at 100°C for 10 minutes, then wash it with hot water for 1~2 times, and wash it with warm water for 1 times, washed in cold water for 2 to 3 times, dehydrated and dried to obtain desized cotton-containing fabric;

[0034]Scouring, adding the obtained desized cotton fabric to the prepared 1L scouring and finishing solution with a temperature of 85°C (caustic soda 25g, surfactant 4g, sodium bisulfite 3g, trisodium phosphate 4g), stirring well Infiltration, second dipping and second rolling on the padding machine, the cotton-containing fabric has a liquid rate of...

Embodiment 2

[0039] S1, pre-processing

[0040] Desizing, using enzyme desizing method for desizing treatment, adding 50g of singeed cotton and linen fabric with a weight ratio of cotton to linen of 1:1, into 1.5L desizing finishing solution (amylase contains 2.5 g, NaCl contains 6g, penetrating agent contains 2g), stir to make it fully infiltrated, double dipping and rolling on the padding machine, the cotton and linen fabric has a liquid rate of 75%, put it in a steamer after standing for 20 minutes, and steam at 102°C Treat for 8 minutes, then wash 1-2 times with hot water, 1 time with warm water, 2-3 times with cold water, dehydrate and dry to obtain desized cotton-containing fabric;

[0041] Scouring, adding the obtained desized cotton and linen fabric to the prepared 1L scouring and finishing solution with a temperature of 85°C (caustic soda 35g, surfactant 6g, sodium bisulfite 4g, trisodium phosphate 4g), stirring fully Infiltration, second dipping and second rolling on a padding m...

Embodiment 3

[0046] S1, pre-processing

[0047] Desizing, using enzyme desizing method for desizing treatment, adding 50g of singeed cotton wool fabric with a weight ratio of cotton to hemp of 2:1, into 1.5L desizing finishing solution (amylase contains 3g, NaCl contains 8g, penetrating agent contains 2g), stir to make it fully infiltrated, double dipping and two rolling on the paddle car, the cotton and wool fabric has a liquid rate of 75%, put it in a steamer after standing for 20 minutes, and steam at 105 ° C for 5 minutes, Then wash with hot water for 1-2 times, warm water for 1 time, cold water for 2-3 times, dehydration and drying to obtain desized cotton-containing fabrics;

[0048] Scouring, adding the obtained desized cotton wool fabric to 1L of scouring and finishing liquid prepared at a temperature of 85°C (caustic soda 45g, surfactant 8g, sodium bisulfite 4g, trisodium phosphate 4g), stirring to fully infiltrate , two dipping and two rolling on the paddle car, the cotton-conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com