Impregnated paper decorative material with mildew-proof effect and preparation method thereof

A decorative material and impregnated paper technology, which is applied in the direction of special paper, pulp raw material addition process, paper, etc., can solve the problems of unfavorable long-term use, affecting appearance, weak mildew resistance, etc., to achieve long-term use, improve use effect, improve The effect of anti-mold and bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

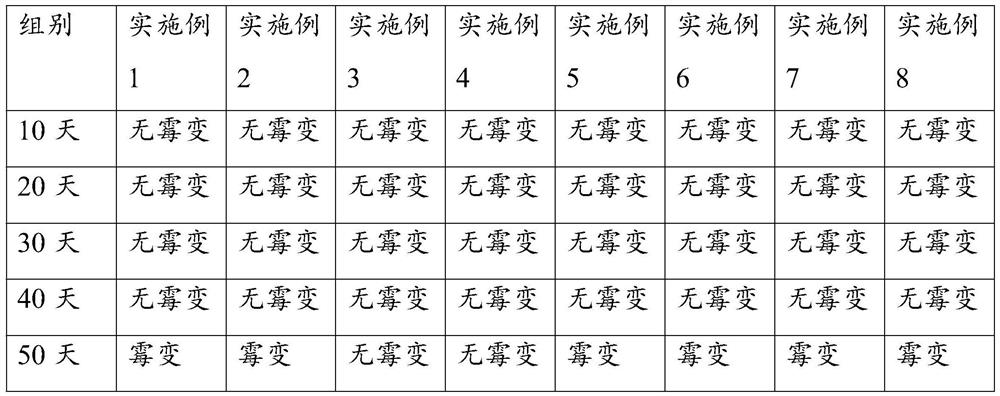

Examples

Embodiment 1

[0024] (1) Preparation of modified layer mixture: Weigh raw materials corresponding to weight parts, 80 parts of melamine, 80 parts of formaldehyde, 40 parts of montmorillonite, 5 parts of ethyl p-hydroxybenzoate, 5 parts of polyvinylpyrrolidone, modified 8 parts of agent and 40 parts of water, then put melamine, formaldehyde, montmorillonite, ethyl p-hydroxybenzoate, polyvinylpyrrolidone and water into the reaction kettle for stirring and mixing, so that the speed is 150r / min and the temperature is 70°C , stirred for 30 minutes, put the modifier into the reaction kettle, and then further increased the temperature to maintain it at 105°C, and at the same time input 3000HZ electromagnetic waves to make the rotation speed 250r / min, stirred for 8 minutes, and then cooled to make the temperature 30°C, you can get Modified layer mix;

[0025] (2) Apply the modified layer mixture prepared in step 1) to the two ends of the base paper respectively, then use a scraper to remove the red...

Embodiment 2

[0029] (1) Preparation of modified layer mixture: Weigh raw materials corresponding to parts by weight, 85 parts of melamine, 85 parts of formaldehyde, 45 parts of montmorillonite, 5.5 parts of ethyl p-hydroxybenzoate, 5.5 parts of polyvinylpyrrolidone, modified 8.5 parts of agent and 45 parts of water, then put melamine, formaldehyde, montmorillonite, ethyl p-hydroxybenzoate, polyvinylpyrrolidone and water into the reaction kettle for stirring and mixing, so that the speed is 150r / min and the temperature is 70°C , stirred for 30 minutes, put the modifier into the reaction kettle, and then further increased the temperature to maintain it at 105°C, and at the same time input 3000HZ electromagnetic waves to make the rotation speed 250r / min, stirred for 8 minutes, and then cooled to make the temperature 30°C, you can get Modified layer mix;

[0030] (2) Apply the modified layer mixture prepared in step 1) to the two ends of the base paper respectively, then use a scraper to remov...

Embodiment 3

[0034] (1) Preparation of modified layer mixture: Weigh raw materials corresponding to weight parts, 90 parts of melamine, 90 parts of formaldehyde, 50 parts of montmorillonite, 6 parts of ethyl p-hydroxybenzoate, 6 parts of polyvinylpyrrolidone, modified 9 parts of agent and 50 parts of water, then put melamine, formaldehyde, montmorillonite, ethyl p-hydroxybenzoate, polyvinylpyrrolidone and water into the reaction kettle for stirring and mixing, so that the speed is 150r / min and the temperature is 70°C , stirred for 30 minutes, put the modifier into the reaction kettle, and then further increased the temperature to maintain it at 105°C, and at the same time input 3000HZ electromagnetic waves to make the rotation speed 250r / min, stirred for 8 minutes, and then cooled to make the temperature 30°C, you can get Modified layer mix;

[0035] (2) Apply the modified layer mixture prepared in step 1) to the two ends of the base paper respectively, then use a scraper to remove the red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com