Automatic gluing device

A glue coating device and power device technology, which is applied to the surface coating liquid device, coating, metal processing equipment, etc., can solve the problems of large safety hazards, high labor intensity, low efficiency, etc., and achieve high-efficiency and automatic operation High degree, the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

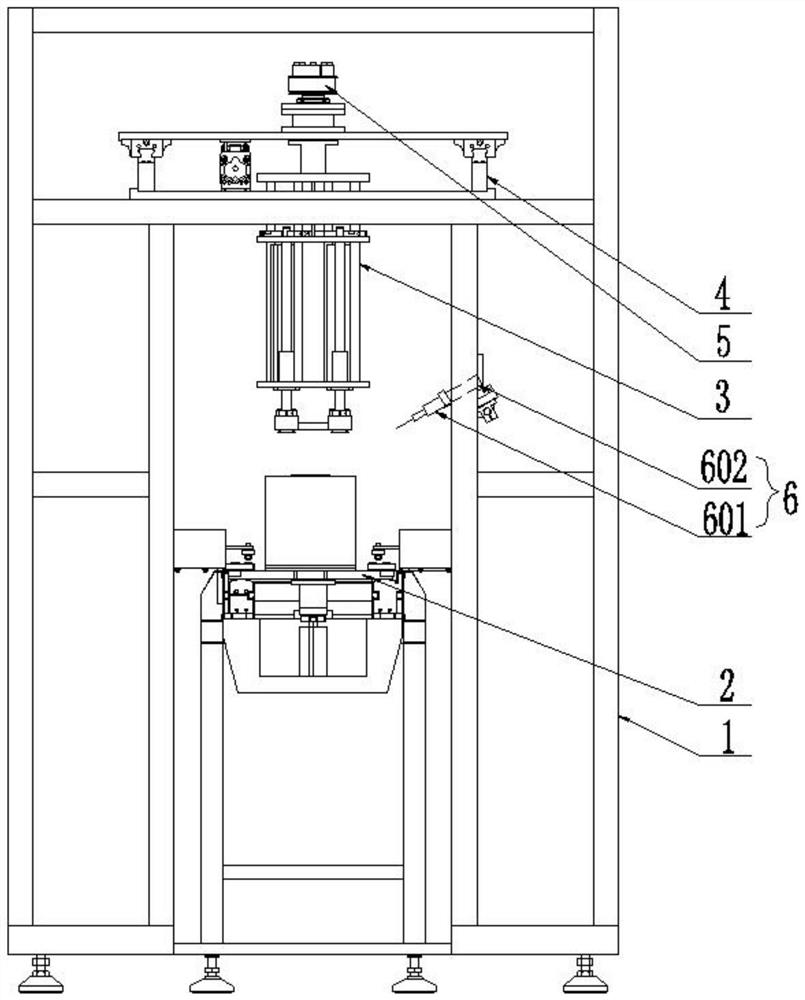

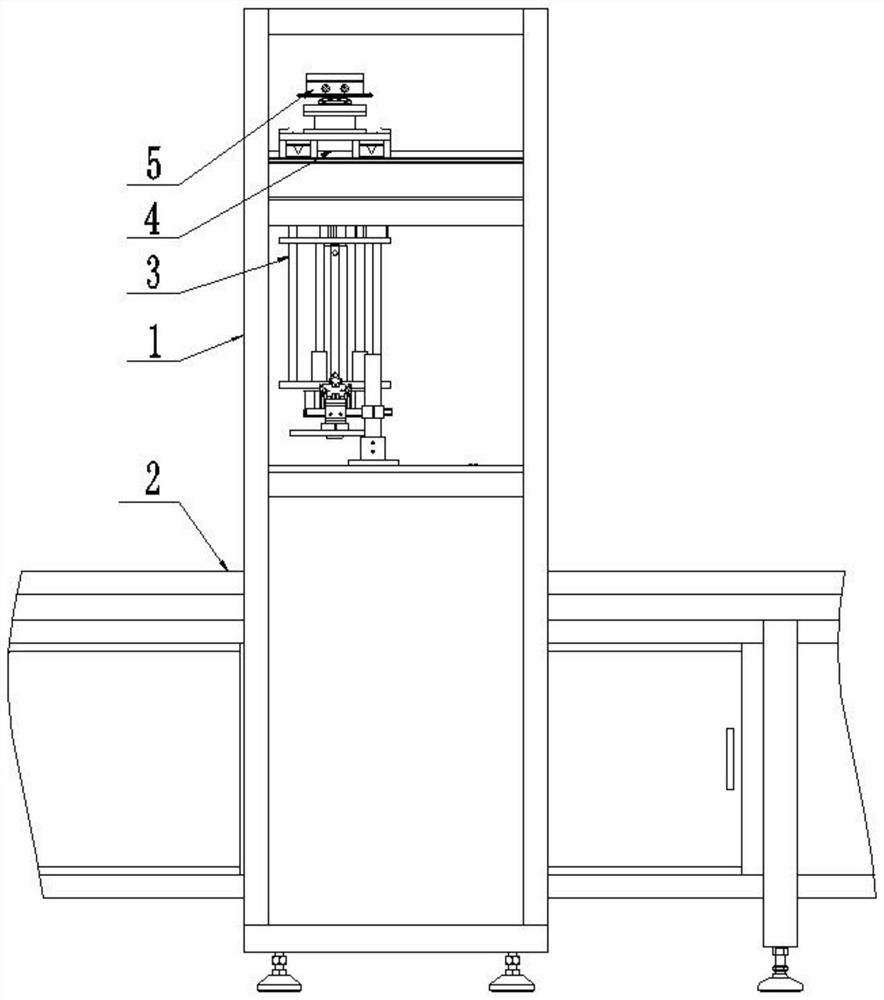

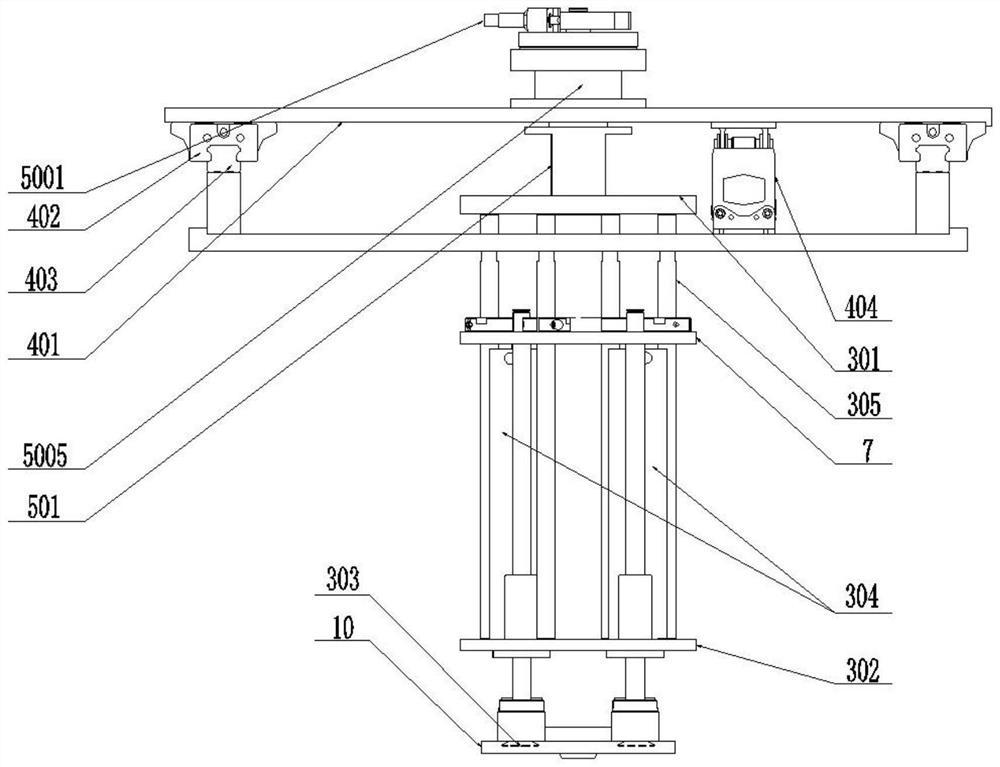

[0038] like figure 1 , figure 2 and image 3As shown, the automatic gluing device of the present invention includes a frame 1, a transmission line 2 arranged in the frame 1, a translation mechanism 4 arranged on the frame 1, a rotation mechanism 5 arranged on the translation mechanism 4, and a rotation mechanism 5. The grasping mechanism 3 connected by the mechanism 5 and the gluing mechanism 6 arranged on the frame 1, the grasping mechanism 3 and the gluing mechanism 6 are arranged above the transmission line 2, and the grasping mechanism 3 includes two fixed intervals. The top plate 301 and the bottom plate 302 arranged at a distance and parallel to each other, the suction cup 303, and the first power device 304 arranged on the bottom plate 302 to drive the suction cup 303 to extend and retract in the vertical direction, the top plate 301 and the bottom plate 302 are connected by a column 305, so The bottom plate 302 is connected with the suction cup 303 through the first...

Embodiment 2

[0040] like Figure 4 , Figure 5 and Image 6 As shown, this embodiment is a further improvement made on the basis of the first embodiment. The third moving device 502 includes a swing cylinder 5001, a first timing pulley 5002 and a second timing pulley 5003 that are connected to the swing cylinder 5001 and can swing synchronously with the swing cylinder 5001. The first timing pulley 5001 is synchronized by The belt 5004 is connected with the second synchronous pulley 5003, and the second synchronous pulley 5003 is connected with the rotating shaft 501 through the bearing 5005; the rotation angle of the swing cylinder 5001 is 270°, and the first synchronous pulley 5002 is connected with the second synchronous belt The ratio of the pitch circle diameters of the wheel 5003 is 1:0.64. This is achieved by using two synchronous pulleys of different sizes, since the ratio of the pitch circle diameters of the first synchronous pulley 5002 and the second synchronous pulley 5002 is...

Embodiment 3

[0042] like Figure 7 As shown, this embodiment is a further improvement made on the basis of the first embodiment. A mounting seat 7 parallel to the bottom plate 302 is also provided on the upright column 305 between the top plate 301 and the bottom plate 302 . The mounting seat 7 is provided with a positioning device, and the positioning device includes a positioning rod 701 and a driving positioning rod 701 The fifth power device 702 that is telescopic in the vertical direction, the mounting seat 7 is connected to the positioning rod 701 through the fifth power device 702; a guide shaft 8 is also provided between the mounting seat 7 and the bottom plate 302; the fifth power device 702 for the cylinder. The positioning of the cylinder cover can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com