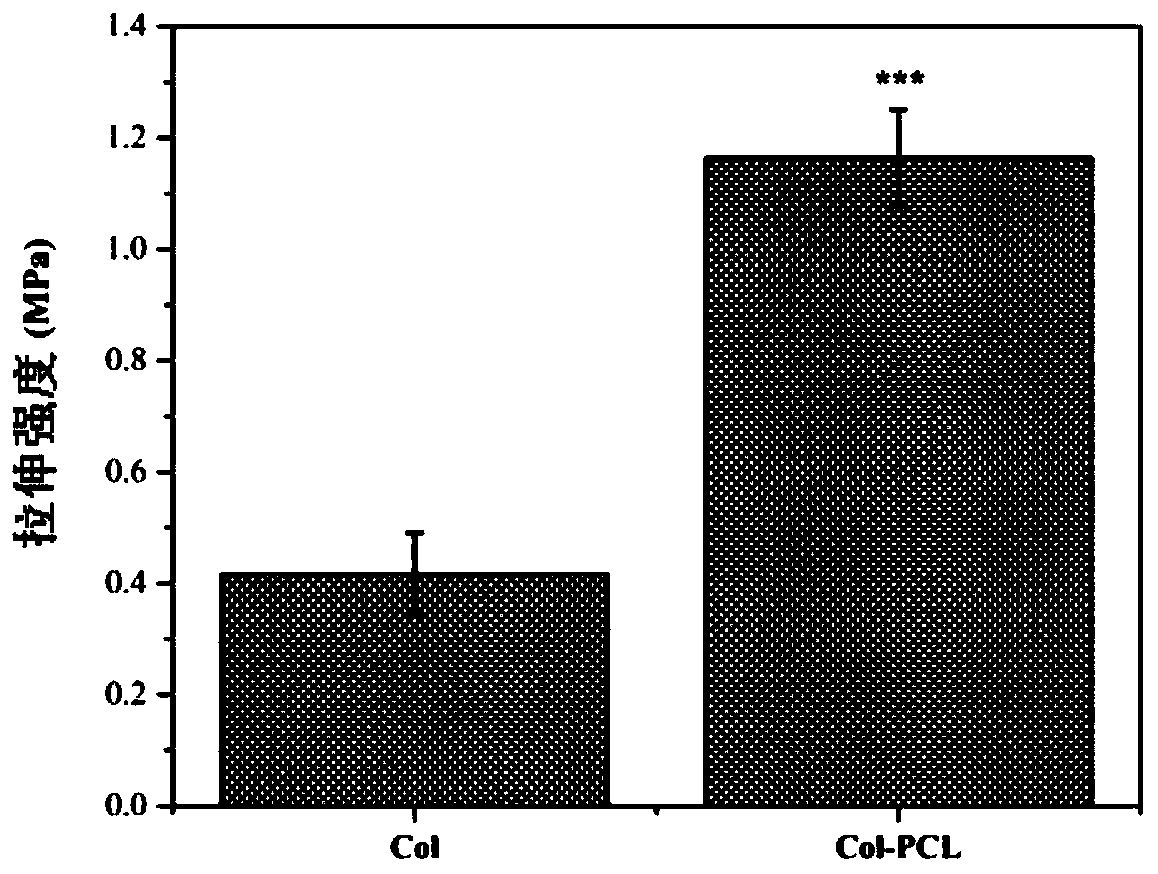

Suture-resistant collagen-based corneal regeneration and repair material and preparation method thereof

A technology for collagen-based cornea and repair materials, applied in suture-resistant collagen-based cornea regeneration and repair materials and its preparation, can solve the problems of insufficient tensile strength and unfavorable conventional suture, and achieve low cost, good composite stability, and biological good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Shred the purified bovine Achilles tendon type Ⅰ collagen with scissors, dissolve it with 0.01mol / L hydrochloric acid solution, and use a laboratory high-shear mixer to shear at high speed under ice bath conditions, and the speed is 6000-7000rpm ;

[0029] (2) Continue stirring the Col solution obtained in step (1) with a stirring paddle, and slowly add a certain amount of 15 mg / mL EDC / NHS cross-linking agent into the stirring Col solution, and stir at 4°C for 24 hours , wherein the mass ratio of Col:EDC:NHS is 6:1:1;

[0030] (3) Get a small amount of crosslinked Col solution in step (2) and concentrate in a far-infrared drying oven, and calculate the concentration of Col solution, and adjust the final concentration of Col solution to be 5mg / mL;

[0031] (4) Slowly stir the Col solution obtained in step (3) at room temperature for 2 hours, and centrifuge to remove air bubbles, wherein the rotating speed of the stirring paddle is 120rpm;

[0032] (5) Inject the Co...

Embodiment 2

[0037] (1) Cut the purified bovine Achilles tendon type Ⅰ collagen with scissors, dissolve it with 0.01mol / L hydrochloric acid solution and shear it at high speed with a laboratory high-shear mixer under ice bath conditions, and the speed is 6000-7000rpm ;

[0038] (2) Continue to stir the Col solution obtained in step (1) with a stirring paddle, and slowly add a certain amount of 15mg / mL EDC / NHS crosslinking agent into the stirring Col solution, and stir at 4°C for 24h , wherein the mass ratio of Col:EDC:NHS is 6:1:1;

[0039] (3) Get a small amount of crosslinked Col solution in step (2) and concentrate in a far-infrared drying oven, and calculate the concentration of Col solution, and adjust the final concentration of Col solution to be 6mg / mL;

[0040] (4) Slowly stir the Col solution obtained in step (3) at room temperature for 2 hours, and centrifuge to remove air bubbles, wherein the rotating speed of the stirring paddle is 120rpm;

[0041](5) Inject the Col solution ...

Embodiment 3

[0045] (1) Cut the purified bovine Achilles tendon type Ⅰ collagen with scissors, dissolve it with 0.01mol / L hydrochloric acid solution and shear it at high speed with a laboratory high-shear mixer under ice bath conditions, and the speed is 6000-7000rpm ;

[0046] (2) Continue to stir the Col solution obtained in step (1) with a stirring paddle, and slowly add a certain amount of 15mg / mL EDC / NHS crosslinking agent into the stirring Col solution, and stir at 4°C for 24h , wherein the mass ratio of Col:EDC:NHS is 6:1:1;

[0047] (3) Get a small amount of crosslinked Col solution in step (2) and concentrate in a far-infrared drying oven, and calculate the concentration of Col solution, and adjust the final concentration of Col solution to be 6.5mg / mL;

[0048] (4) Slowly stir the Col solution obtained in step (3) at room temperature for 2 hours, and centrifuge to remove air bubbles, wherein the rotating speed of the stirring paddle is 120rpm;

[0049] (5) Inject the Col soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com