Preparation method of microencapsulated flame retardant

A technology of microencapsulation and flame retardant, applied in the field of flame retardant materials, can solve problems such as poor dispersion and affect the strength of materials, and achieve the effects of reducing dosage, saving costs and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

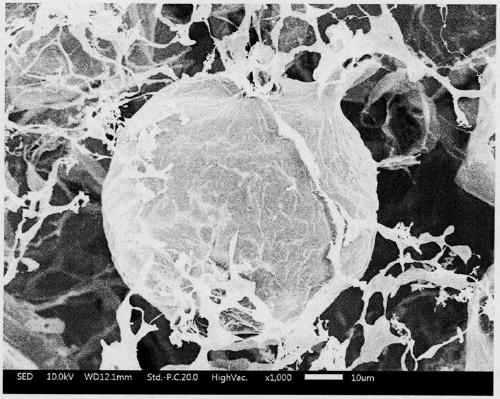

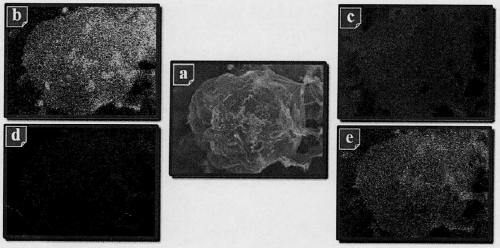

Image

Examples

Embodiment 1

[0019] A preparation method of microcapsules with good flame retardant properties, comprising the steps of:

[0020] 1) Chitosan hydrochloride powder was added to 600ml deionized water, and stirred at 300rpm / min for 30min to obtain a homogeneous solution;

[0021] 2) Add the ammonium polyphosphate suspension liquid that has been ultrasonically treated for 6 minutes into the solution prepared in step (1), the mass ratio of ammonium polyphosphate to chitosan hydrochloride is 1:3, and fully stir to obtain microencapsulated polyphosphoric acid ammonium; suction filtration, washing to obtain ammonium polyphosphate microcapsules containing a small amount of water.

[0022] 3) Add the microcapsules obtained in step (2) into the suspension containing carboxyl-modified nanocellulose, stir continuously to make it evenly mixed, and pour the mixed solution into the mold, wherein the carboxyl-modified nanocellulose and microcapsules The mass ratio of ammonium polyphosphate is 7: 3;

[00...

Embodiment 2

[0029] A preparation method of microcapsules with good flame retardant properties, comprising the steps of:

[0030] 3) Chitosan hydrochloride powder was added to 600ml deionized water, and stirred at 300rpm / min for 30min to obtain a homogeneous solution;

[0031] 4) Add the ammonium polyphosphate suspension solution that was ultrasonically treated for 6 minutes into the solution prepared in step (1), the mass ratio of ammonium polyphosphate to chitosan hydrochloride was 1:3, and fully stirred to obtain microencapsulated polyphosphoric acid ammonium; suction filtration, washing to obtain ammonium polyphosphate microcapsules containing a small amount of water.

[0032] 3) Add the microcapsules obtained in step (2) into the suspension containing carboxyl-modified nanocellulose, stir continuously to make it evenly mixed, and pour the mixed solution into the mold, wherein the carboxyl-modified nanocellulose and microcapsules The mass ratio of ammonium polyphosphate is 1:1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com