Fully degradable non-woven material for medical treatment and public health

A medical and sanitary, non-woven technology, applied in the field of medical and sanitary materials, can solve the problems of insufficient antibacterial and bacteriostatic properties, incomplete degradation, poor strength or toughness, etc., and achieves good water absorption effect, excellent moisture absorption performance, and high use comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

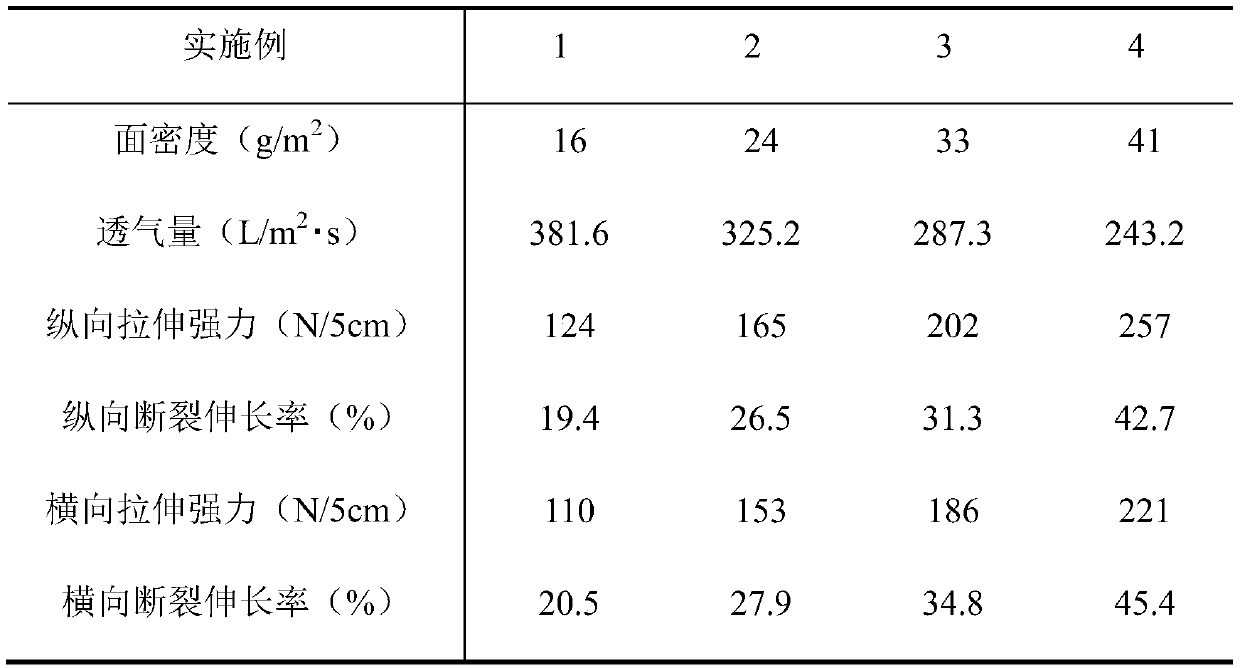

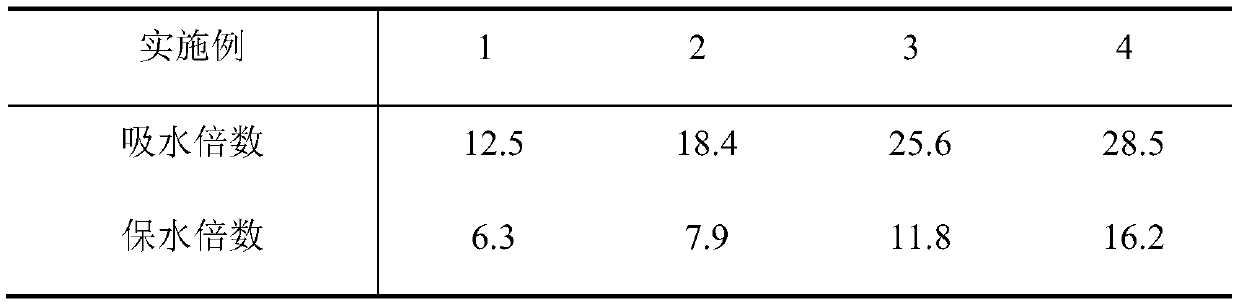

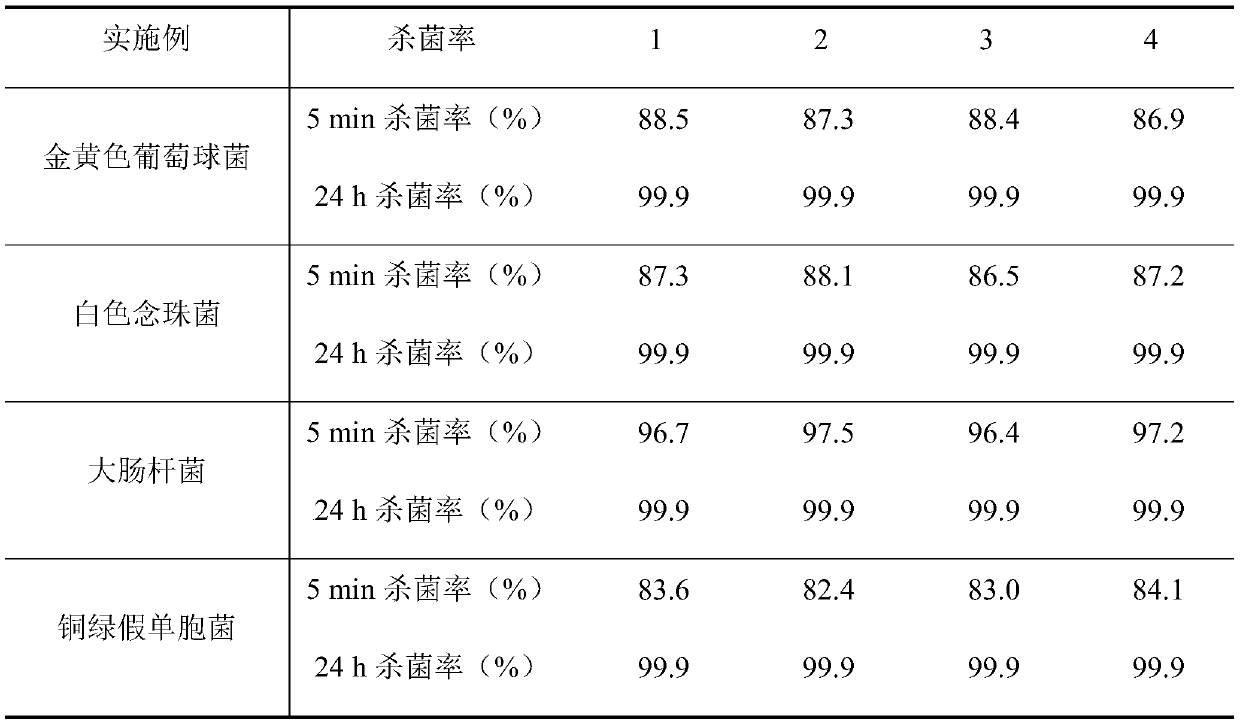

Examples

Embodiment 1

[0030] A fully degradable non-woven fabric material for medical and sanitation. The non-woven fabric material is composed of polyvinyl alcohol grafted modified polylactic acid, polybutylene succinate, modified lignin, dopamine, and nano-silver.

[0031] Further, the preparation method of the modified lignin is to carry out wet ball milling of lignin, and then use ionic liquids [Bmim]Cl and [Emim]OAc to modify the lignin after ball milling to obtain modified lignin .

[0032] Further, the synthesis method of polyvinyl alcohol grafted modified polylactic acid is as follows: adding polyvinyl alcohol into dry DMSO, after dissolving, adding stannous octoate toluene solution with a mass concentration of 0.4% to 0.5%, stirring Transfer to the polymerization reactor after being uniform; another lactide is dissolved in dry DMSO, and then added to the polymerization reactor; the polymerization reactor is heated to 90°C after 3 times of vacuuming and nitrogen filling, and the reaction is...

Embodiment 2

[0043] A fully degradable non-woven fabric material for medical and sanitation. The non-woven fabric material is composed of polyvinyl alcohol grafted modified polylactic acid, polybutylene succinate, modified lignin, dopamine, and nano-silver.

[0044] Further, the preparation method of the modified lignin is to carry out wet ball milling of lignin, and then use ionic liquids [Bmim]Cl and [Emim]OAc to modify the lignin after ball milling to obtain modified lignin .

[0045] Further, the synthesis method of polyvinyl alcohol grafted modified polylactic acid is as follows: adding polyvinyl alcohol into dry DMSO, after dissolving, adding stannous octoate toluene solution with a mass concentration of 0.4% to 0.5%, stirring Transfer to the polymerization reactor after being uniform; another lactide is dissolved in dry DMSO, and then added to the polymerization reactor; the polymerization reactor is heated to 90°C after 3 times of vacuuming and nitrogen filling, and the reaction is...

Embodiment 3

[0056] A fully degradable non-woven fabric material for medical and sanitation. The non-woven fabric material is composed of polyvinyl alcohol grafted modified polylactic acid, polybutylene succinate, modified lignin, dopamine, and nano-silver.

[0057] Further, the preparation method of the modified lignin is to carry out wet ball milling of lignin, and then use ionic liquids [Bmim]Cl and [Emim]OAc to modify the lignin after ball milling to obtain modified lignin .

[0058] Further, the synthesis method of polyvinyl alcohol grafted modified polylactic acid is as follows: adding polyvinyl alcohol into dry DMSO, after dissolving, adding stannous octoate toluene solution with a mass concentration of 0.4% to 0.5%, stirring Transfer to the polymerization reactor after being uniform; another lactide is dissolved in dry DMSO, and then added to the polymerization reactor; the polymerization reactor is heated to 90°C after 3 times of vacuuming and nitrogen filling, and the reaction is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com