Porous ceramic material, solid electrolyte material as well as preparation method and lithium ion battery thereof

A solid electrolyte, porous ceramic technology, applied in ceramic products, secondary batteries, circuits, etc., can solve the problems of insufficient promotion of lithium ion conduction efficiency, stability, insufficient ion conductivity, and insufficient lithium ion conduction efficiency, and achieve good Lithium ion conductivity and stability, the effect of improving lithium ion conductivity and stability, and good lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] Another aspect of the present invention provides a method for preparing a solid electrolyte material, comprising the following steps:

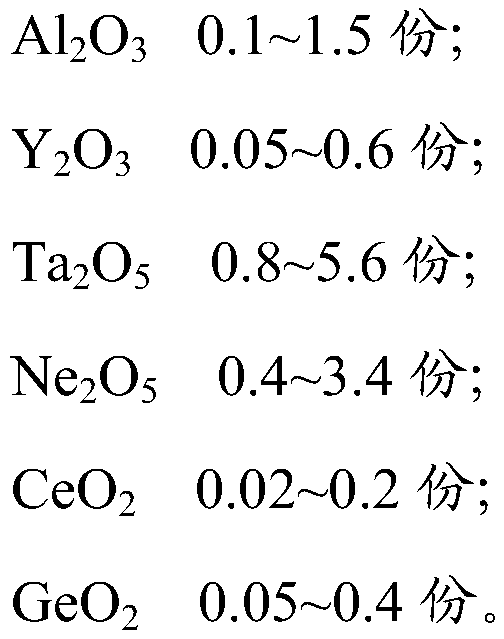

[0072] S01: Put Li 7 La 3 Zr 2 o 12 100 copies, Li 7 La 3 Zr 2 o 12 For LiOH, La 2 o 3 and ZrO 2 Formed according to the chemical formula; Al 2 o 3 0.1~1.5 copies; Y 2 o 3 0.05~0.6 parts; Ta 2 o 5 0.8~5.6 parts; Ne 2 o 5 0.4~3.4 parts; CeO 2 0.02~0.2 parts; GeO 2 0.05 to 0.4 parts of sintering treatment, each of the raw materials is powder, to obtain a ceramic material precursor;

[0073] S02: pulverize the ceramic material precursor, and undergo secondary sintering to obtain a porous ceramic material;

[0074] S03: activating the porous ceramic material;

[0075] S04: Fill the pores of the activated porous ceramic material with an organic lithium ion compound and perform annealing treatment, the organic lithium ion conductor includes 30-50 parts by mass of polyvinylidene fluoride, 20-30 parts by mass Polyethy...

Embodiment 1

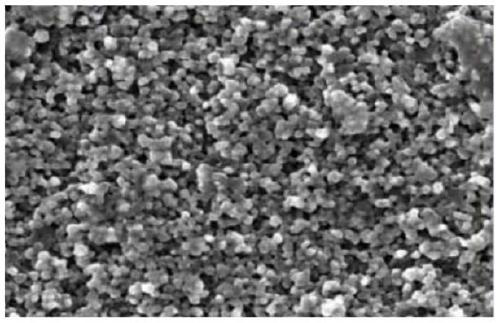

[0085] On the one hand, this embodiment provides a porous ceramic material, which is prepared by the following preparation method: weigh 700g of LiOH, 150g of La 2 o 3 and 200g of ZrO 2 The chemical formula of the powder composition ratio is Li 7 La 3 Zr 2 o 12 The composition of; and Al 2 o 3 0.1g, Y 2 o 3 0.05g, Ta 2 o 5 1g, Ne 2 o 5 2.4g, CeO 2 0.05g and GeO 2 The powder of 0.2g is uniformly dispersed and mixed by ball milling; the porous ceramic precursor is synthesized in an argon high temperature and high pressure sintering furnace. The temperature is 900°C, the argon pressure is 20MPa, and the sintering time is 3h.

[0086] The above-mentioned porous ceramic precursor is prepared into a uniform and dense powder by vibrating ball mill crushing and grinding, and then microwave sintered in a microwave sintering furnace, and the powder particles form sintering necks to form a bond to prepare a porous ceramic material. The microwave temperature is 900°C,...

Embodiment 2

[0096] On the one hand, this embodiment provides a porous ceramic material, which is prepared by the following preparation method: weigh 700g of LiOH, 150g of La 2 o 3 and 200g of ZrO 2 The chemical formula of the powder composition ratio is Li 7 La 3 Zr 2 o 12 Composition; Al 2 o 3 1g, Y 2 o 3 0.5g, Ta 2 o 5 2.3g, Ne 2 o 5 1.4g, CeO 2 0.02g and GeO 2 The powder of 0.1 g is uniformly dispersed and mixed by ball milling; the porous ceramic precursor is synthesized in an argon high-temperature and high-pressure sintering furnace. The temperature is 900°C, the argon pressure is 30MPa, and the sintering time is 5h.

[0097] The above-mentioned porous ceramic precursor is prepared into a uniform and dense powder by vibrating ball mill crushing and grinding, and then microwave sintered in a microwave sintering furnace, and the powder particles form sintering necks to form a bond to prepare a porous ceramic material. The microwave temperature is 900°C, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com