A kind of preparation method of mixed matrix flat film of mof particle modification nanotube filling silicone rubber

A mixed matrix, flat membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of reducing membrane selectivity, MMMs difficult to maintain high mechanical properties and high selectivity, uneven dispersion, etc. problems, to achieve the effect of improving separation capacity and efficiency, improving osmotic separation performance, and improving osmotic separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

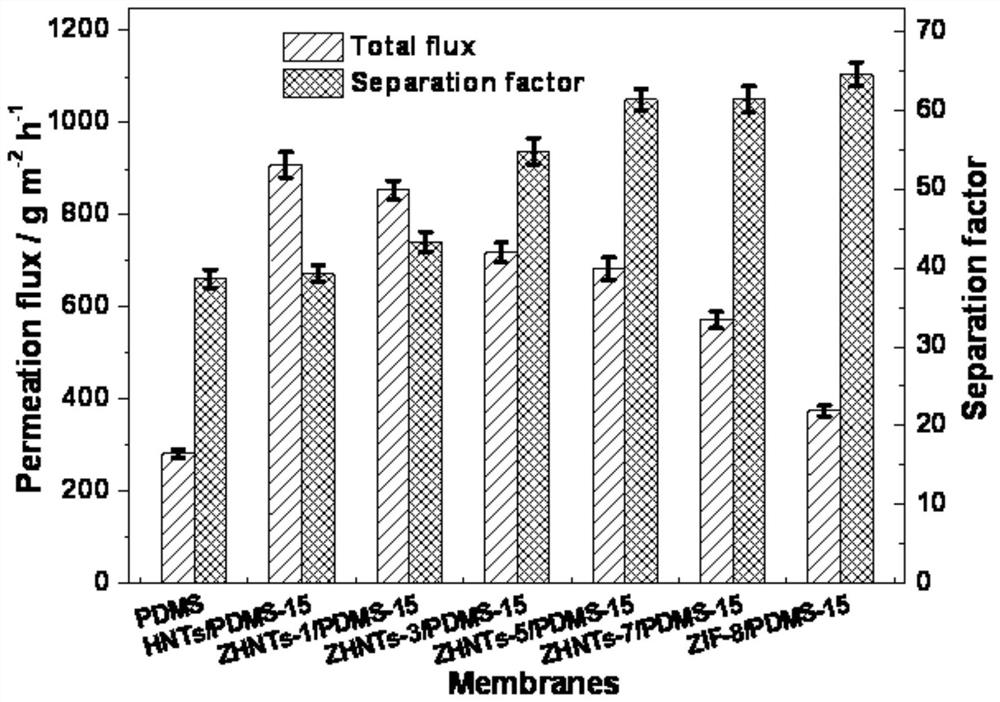

Embodiment 1

[0025] A method for preparing a MOF particle-modified nanotube filled silicone rubber mixed matrix flat film, the specific preparation steps are as follows:

[0026] 1) Add 5 g of halloysite nanotubes into a mixed solution of 180 ml of tetrahydrofuran and 40 ml of water to obtain dispersion 1.

[0027] 2) Add 2.5 g of dopamine to the dispersion 1 obtained in step 1 to obtain a suspension 2.

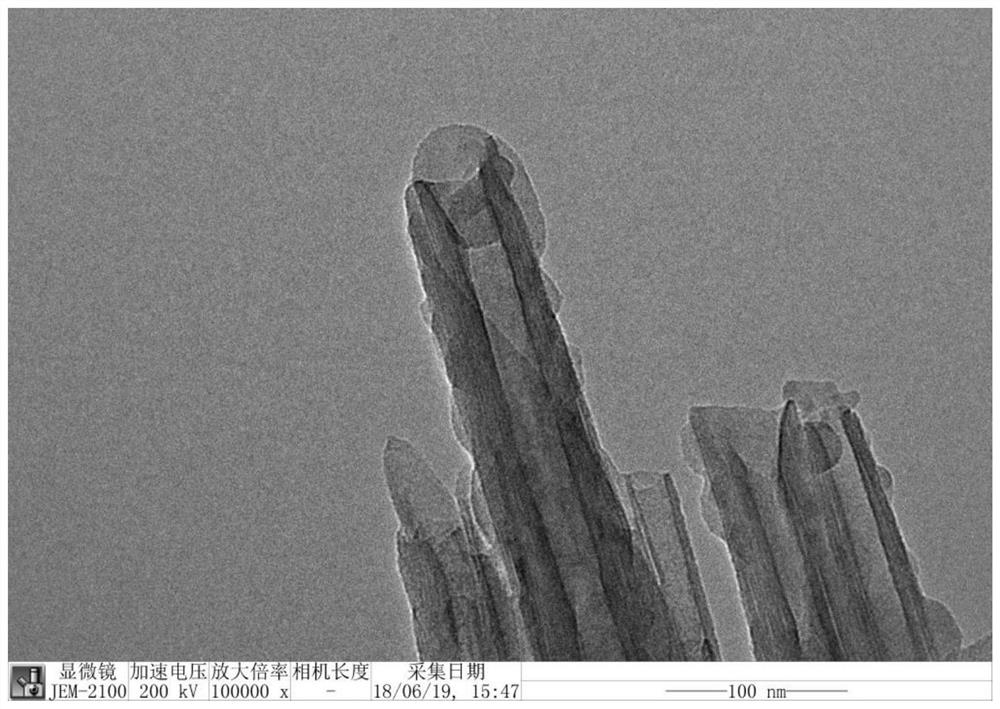

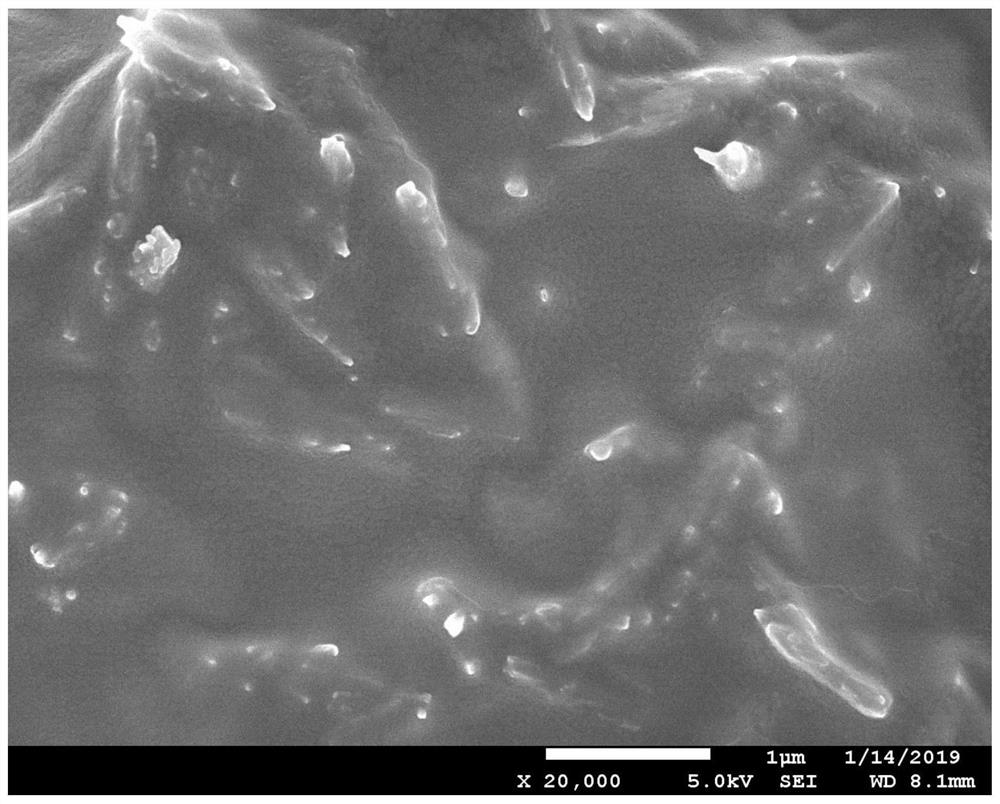

[0028] 3) The suspension 2 obtained in step 2 was continuously stirred for 48 hours, and vacuumized at room temperature. Centrifuge, wash the precipitate with THF and water for 4 times, and then dry the precipitate at 60°C under vacuum for 8h to constant weight to obtain dopamine-modified halloysite nanotubes (DHNTs);

[0029] 4) Disperse 0.5g of DHNTs obtained in step 3 in 15ml of 0.05mol / ml Zn(NO 3 ) 2 ·6H 2 O methanol solution for 10 minutes to obtain dispersion 2. Then the dispersion 2 was poured into 15 ml of 0.4 mol / L 2-methylimidazole methanol solution to react for 10 minutes....

Embodiment 2

[0035] A method for preparing a MOF particle-modified nanotube filled silicone rubber mixed matrix flat film, the specific preparation steps are as follows:

[0036] 1) Add 5 g of halloysite nanotubes into a mixed solution of 180 ml of tetrahydrofuran and 40 ml of water to obtain dispersion 1.

[0037] 2) Add 2.5 g of dopamine to the dispersion 1 obtained in step 1 to obtain a suspension 2.

[0038] 3) The suspension 2 obtained in step 2 was continuously stirred for 48 hours, and vacuumized at room temperature. Centrifuge, wash the precipitate with THF and water for 4 times, and then dry the precipitate at 60°C under vacuum for 8h to constant weight to obtain dopamine-modified halloysite nanotubes (DHNTs);

[0039] 4) Disperse 0.5g of DHNTs obtained in step 3 in 15ml of 0.05mol / ml Zn(NO 3 ) 2 ·6H 2 O methanol solution for 10 minutes to obtain dispersion 2. Then the dispersion 2 was poured into 15 ml of 0.4 mol / L 2-methylimidazole methanol solution to react for 10 minutes....

Embodiment 3

[0045] A method for preparing a MOF particle-modified nanotube filled silicone rubber mixed matrix flat film, the specific preparation steps are as follows:

[0046] 1) Add 5 g of halloysite nanotubes into a mixed solution of 180 ml of tetrahydrofuran and 40 ml of water to obtain dispersion 1.

[0047] 2) Add 2.5 g of dopamine to the dispersion 1 obtained in step 1 to obtain a suspension 2.

[0048] 3) The suspension 2 obtained in step 2 was continuously stirred for 48 hours, and vacuumized at room temperature. Centrifuge, wash the precipitate with THF and water for 4 times, and then dry the precipitate at 60°C under vacuum for 8h to constant weight to obtain dopamine-modified halloysite nanotubes (DHNTs);

[0049] 4) Disperse 0.5g of DHNTs obtained in step 3 in 15ml of 0.05mol / ml Zn(NO 3 ) 2 ·6H 2 O methanol solution for 10 minutes to obtain dispersion 2. Then the dispersion 2 was poured into 15 ml of 0.4 mol / L 2-methylimidazole methanol solution to react for 10 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com